A kind of rigid polyurethane foam waste recycling spraying method

A technology of rigid polyurethane and foam waste, applied in the direction of coating, device for coating liquid on the surface, etc., can solve the problems of lack of technology and difficulty in recycling and reusing rigid polyurethane, so as to save new materials, reduce pollution, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A kind of rigid polyurethane foam waste reuse spraying method, comprises the following steps:

[0020] Step S1, preparing white material, black material and polyurethane regenerated material, the mass ratio of each component is: 1 part of white material, 1 part of black material, 0.1 part of polyurethane grinding material; the white material is polyurethane Rigid foam combined polyether, the black material is isocyanate, and the polyurethane recycled material is the particles made of hard polyurethane foam waste after cleaning and drying, and the particle size of the polyurethane recycled material is 80-400 mesh;

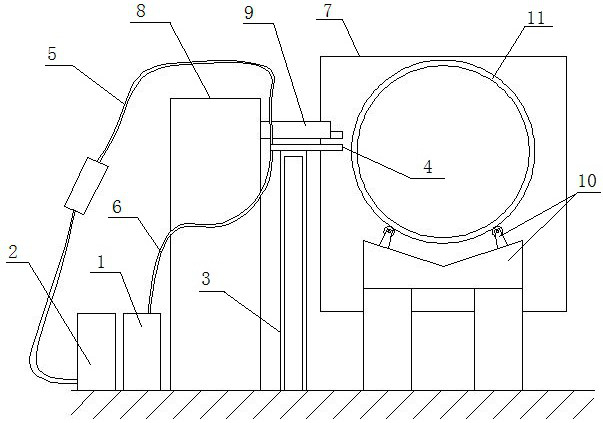

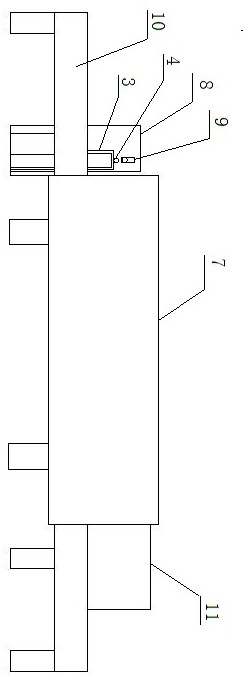

[0021] Step S2, select a fully automatic inner tube spiral transmission line 10 and high-pressure spray foaming equipment 8, the fully automatic inner tube spiral transmission line 10 is provided with a heating device 7 for heating the inner tube, and prepare the inner tube in step S1 The white material and the black material are put into the storage tank of ...

Embodiment 2

[0026] A kind of rigid polyurethane foam waste reuse spraying method, comprises the following steps:

[0027] Step S1, preparing white material, black material and polyurethane recycled material, the mass ratio of each component is: 1 part of white material, 1.5 parts of black material, 0.2 part of polyurethane recycled material; the white material is polyurethane hard Foam combined polyether, the black material is isocyanate, and the polyurethane recycled material is the particles made of hard polyurethane foam waste after cleaning and drying, and the particle size of the polyurethane recycled material is 80-400 mesh;

[0028] Step S2, same as step S2 of embodiment 1;

[0029] Step S3, spraying and foaming. During spraying and foaming, synchronous powder blowing operation is carried out under the high-pressure spray gun 9 of the high-pressure spraying and foaming equipment 8. The inner tube 11 of the heat preservation pipe with a diameter of 1.2 meters advances in a spiral th...

Embodiment 3

[0033] A kind of rigid polyurethane foam waste reuse spraying method, comprises the following steps:

[0034] Step S1, preparing white material, black material and polyurethane recycled material, the mass ratio of each component is: 1 part of white material, 1.5 parts of black material, 0.15 part of polyurethane recycled material; the black material is isocyanate, The white material is polyurethane hard foam combined with polyether, and the polyurethane recycled material is the particles made by washing and drying the rigid polyurethane foam waste, and the particle size of the polyurethane recycled material is 80-400 mesh;

[0035] Step S2, same as step S2 of embodiment 1;

[0036] Step S3, spraying and foaming. During spraying and foaming, synchronous powder blowing operation is carried out under the high-pressure spray gun 9 of the high-pressure spraying and foaming equipment 8. The inner tube 11 of the heat preservation pipe with a diameter of 1.2 meters advances in a spira...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com