Laser foaming aid composition as well as preparation method and application thereof

A technology of foaming aids and foaming polymers, which is applied in the field of laser foaming aid compositions and its preparation, can solve problems affecting personnel health, increase raw material costs and manufacturing costs, limit application fields, etc., and achieve improved laser Absorption capacity, good laser foaming effect, effect of increasing crystallization speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

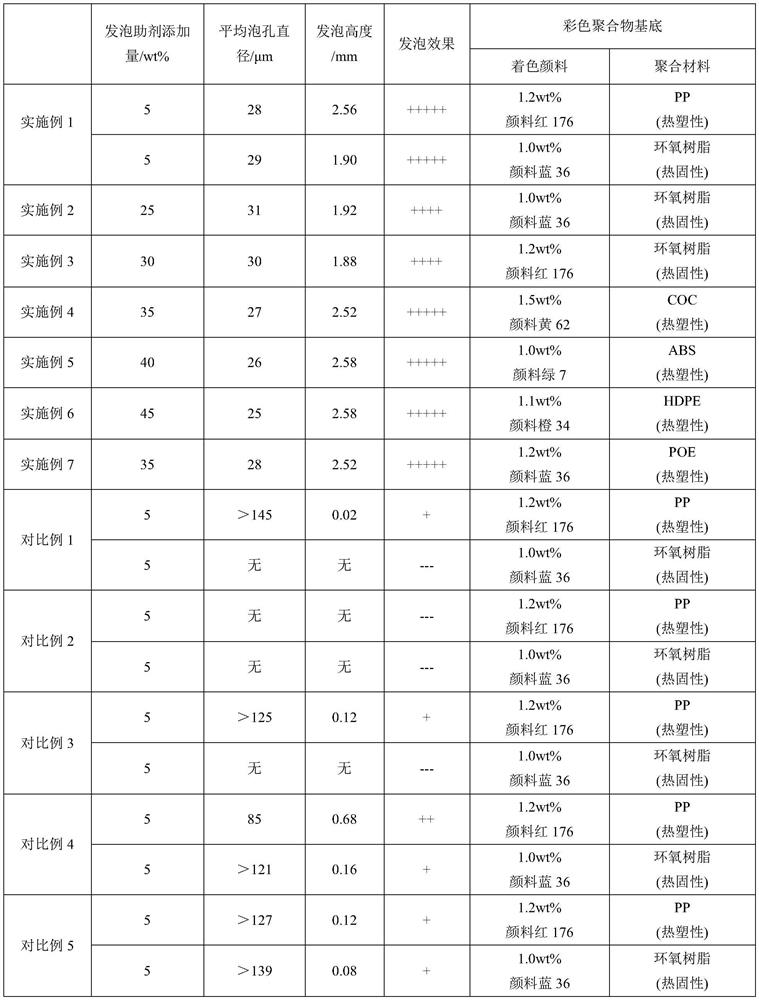

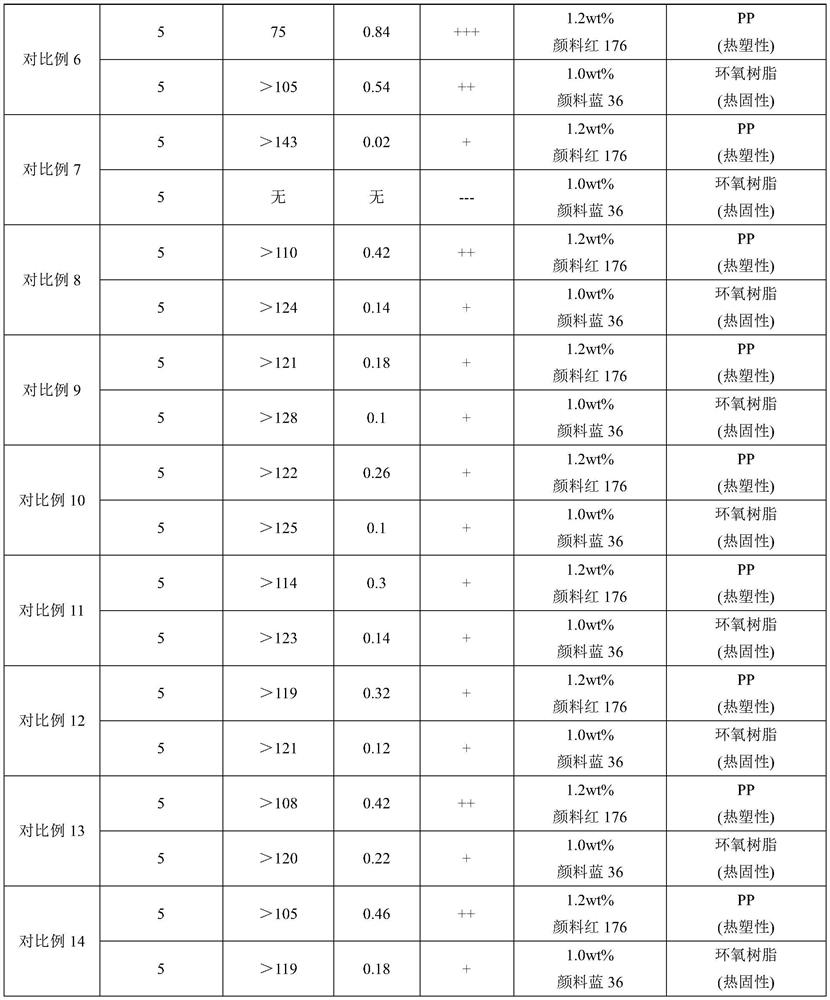

Embodiment 1

[0073] (1) Preparation of laser foaming aid composition:

[0074] 1) 10g polystyrene is dissolved in 100mL toluene to obtain polystyrene toluene solution;

[0075] 2) 9g graphene oxide (the average sheet diameter is 8 μm, the number of sheet layers is 5 layers, and the oxygen content is 25wt%) and 1g boron nitride (the average sheet diameter is 10 μm, and the number of sheet layers is 15 layers, ) were mixed evenly, dispersed in 100mL ethanol, and ultrasonically treated for 18h (ultrasonic power was 1300W) to obtain a graphene oxide / boron nitride ethanol dispersion;

[0076] 3) Add 0.2g KH-550 to the mixed solution of 2mL deionized water / 50mL ethanol for pre-hydrolysis for 3h, the pre-hydrolysis temperature is 25°C, and then mix it with graphene oxide / boron nitride ethanol dispersion evenly, Obtain the dispersion mixture;

[0077] 4) Add the polystyrene toluene solution to the dispersion mixture drop by drop, and continuously stir, the stirring speed is controlled at 500r / mi...

Embodiment 2

[0085] (1) Preparation of laser foaming aid composition:

[0086] 1) 0.5g polycarbonate is dissolved in 100mL methylene chloride to obtain polycarbonate methylene chloride solution;

[0087] 2) 7.5g graphene oxide (average sheet diameter is 16 μm, sheet number is 39 layers, oxygen content is 30wt%) and 0.5g boron nitride (average sheet diameter is 15 μm, sheet number is 90 layer) were mixed evenly, dispersed in 100mL ethanol, and ultrasonically treated for 15h (ultrasonic power was 1500W) to obtain a graphene oxide / boron nitride ethanol dispersion;

[0088] 3) Add 0.15g KH-570 to the mixed solution of 1.5mL deionized water / 50mL ethanol for pre-hydrolysis for 2.5h, the pre-hydrolysis temperature is 45°C, and then homogenize it with the graphene oxide / boron nitride ethanol dispersion Mix to obtain a dispersion mixture;

[0089] 4) Add the polycarbonate dichloromethane solution dropwise into the dispersion mixture, and continuously stir, the stirring speed is controlled at 200r / m...

Embodiment 3

[0094] (1) Preparation of laser foaming aid composition:

[0095] 1) 15g polycarbonate is dissolved in 30mL methylene chloride to obtain polycarbonate methylene chloride solution;

[0096] 2) 5g graphene oxide (the average sheet diameter is 15 μm, the number of sheet layers is 45 layers, and the oxygen content is 35wt%) and 1g boron nitride (the average sheet diameter is 12 μm, and the number of sheet layers is 113 layers) Mix evenly, disperse in 100mL ethanol, and sonicate for 15h (ultrasonic power is 800W) to obtain graphene oxide / boron nitride ethanol dispersion;

[0097] 3) Add 0.05g KH-560 to the mixed solution of 1mL deionized water / 25mL ethanol for pre-hydrolysis for 1.5h, the pre-hydrolysis temperature is 60°C, and then mix it evenly with graphene oxide / boron nitride ethanol dispersion , to obtain the dispersion mixture;

[0098] 4) Add the polycarbonate dichloromethane solution dropwise into the dispersion mixture, and continuously stir, the stirring speed is contro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com