Automatic assembly equipment and method for excavator caterpillar band

A technology for assembly equipment and assembly methods, which is applied in metal processing equipment, assembly machines, metal processing, etc., can solve problems such as the inability to guarantee the straightness of crawler tracks and affect the assembly tempo, and achieve high production efficiency, low safety hazards, and improved product quality. The effect of quality and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

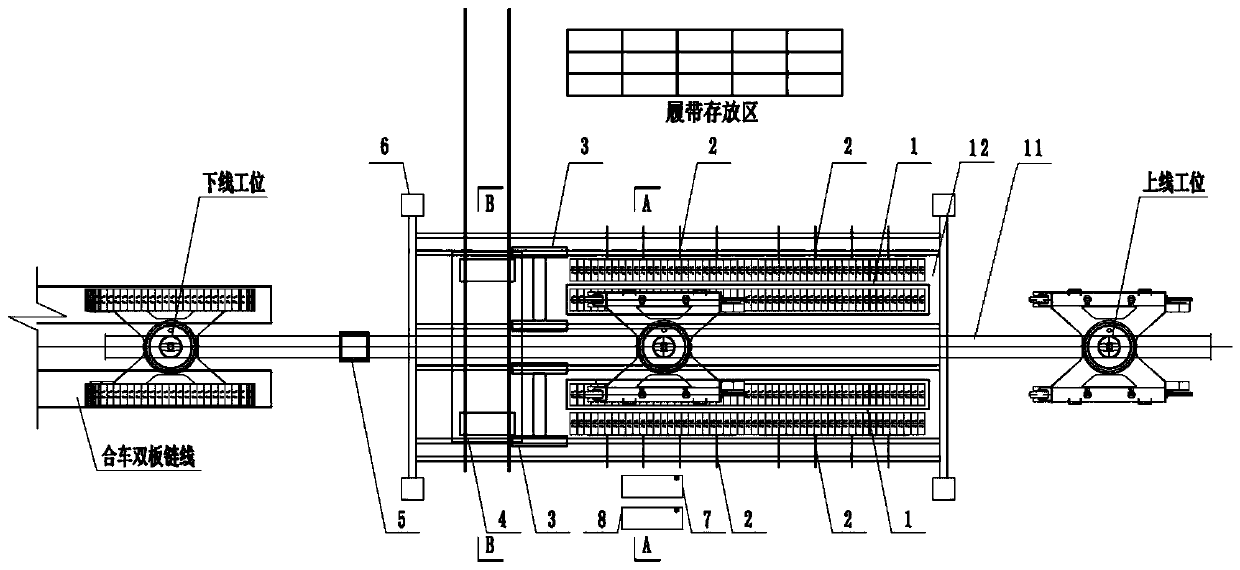

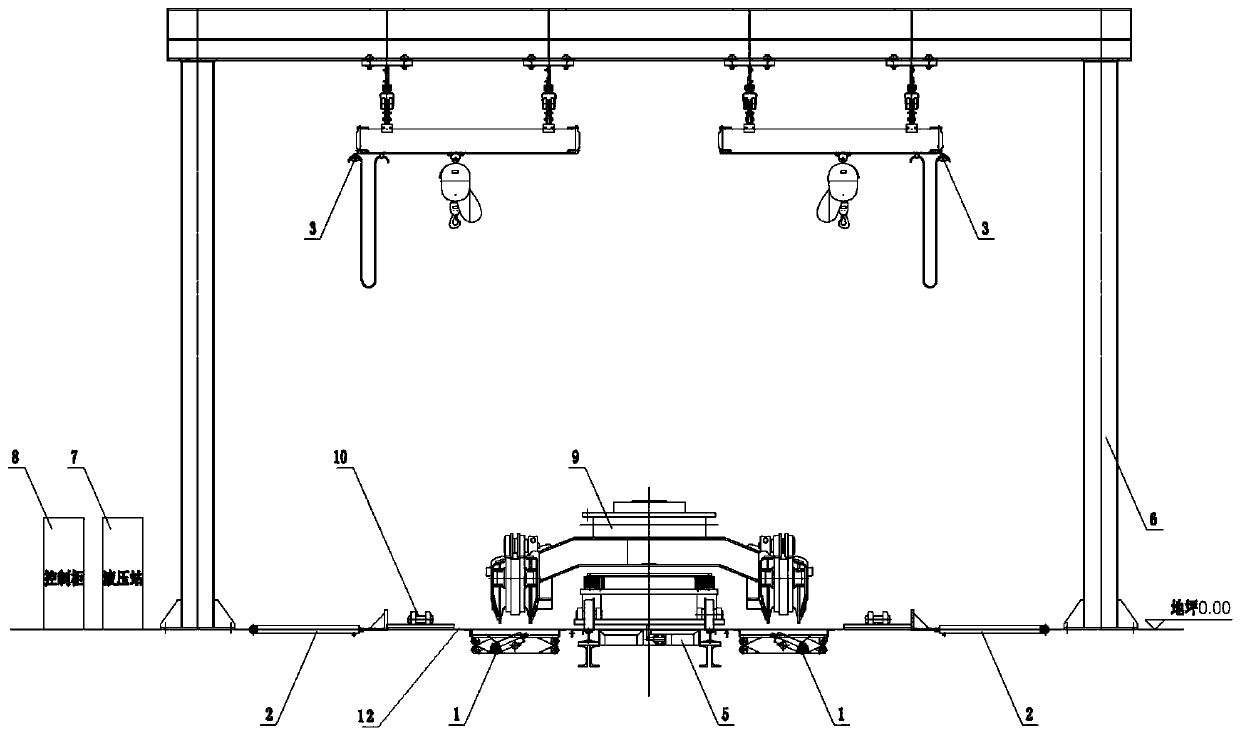

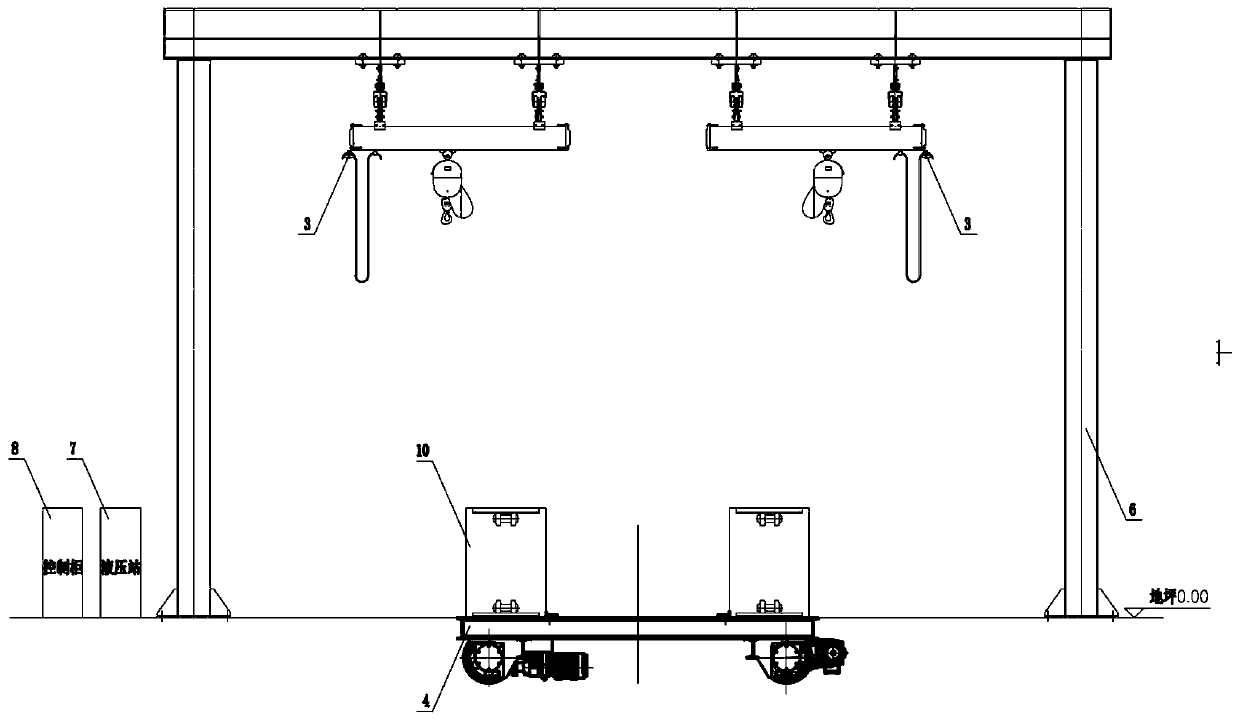

[0040] Such as Figure 1-3 As shown, the excavator crawler automatic assembly equipment in this embodiment includes: a shuttle car 5 with a lifting structure, which walks on the assembly station line 11 and is used to carry the lower frame assembly 9; a conveyor 4, transporting the crawler belt 10 To both sides of the assembly station line 11, the transportation direction is perpendicular to the assembly station line 11, and the conveyor adopts an electric cart powered by a low-voltage rail; the uncoiler 3 is located on both sides of the assembly station line 11 and lifts the crawler 10 is flattened or wrapped; spreading platform 12 is located on both sides of assembly station line 11 and carries crawlers 10 in a flattened shape; rail chain pin pressing machine (not shown), presses crawler belts 10 and rail chains are connected , and the conveyor 4 is provided with a double station corresponding to the spreading platform 12 on both sides of the assembly station line 11 and use...

Embodiment 2

[0055] The difference between this embodiment and the first embodiment is that it further includes a pusher 2 arranged on the spreading platform 12 and pushing the flattened track to the wrapping position. Like this, utilize pushing machine to be able to guarantee that the caterpillar belt that is flattened on the spreading platform is adjusted to straight line, and is positioned at the crawler belt assembly position of lower vehicle frame assembly just below, is conducive to crawler belt assembly. In order to further ensure the straightness of the track, hydraulic cylinders, air cylinders or electro-hydraulic push rods with synchronous valves can be used for the power components of multiple pushers to facilitate the effective calibration of the track; There is a positioning belt on the side, so that the crawler can be accurately positioned at the position to be wrapped and ensure the straightness of the pushed crawler.

[0056] The assembly method of this scheme can generally...

Embodiment 3

[0058] The difference between this embodiment and the above-mentioned embodiment is that the elevators 1 located on both sides of the assembly station line 11 and directly below the assembly positions of the crawler belts 10 on both sides of the lower frame assembly 19 are used to replace the elevators 1 of the shuttle car 5. structure. In this way, without lifting or lowering the lower frame assembly through the lifting function of the shuttle car, the crawler belt can be raised to the assembly position through the lifting of the elevator, so that the unwinder can wrap the crawler belt on the lower frame assembly assembly.

[0059] The upper plane of the elevator 1 in this embodiment is flush with the upper surface of the spreading platform 12 when it is not jacked up, which does not affect the flattening of the caterpillar belt by the unwinding machine on the spreading platform or interferes with the work of the pusher.

[0060] The power components of the plurality of elev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com