Center plate mounting surface structure of carbon fiber hub

A mounting surface, carbon fiber technology, applied in the direction of wheels, transportation and packaging, wheels made of non-metallic materials, etc., can solve problems such as corrosion screws, potential differences, safety hazards, etc., and achieve the effect of avoiding wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

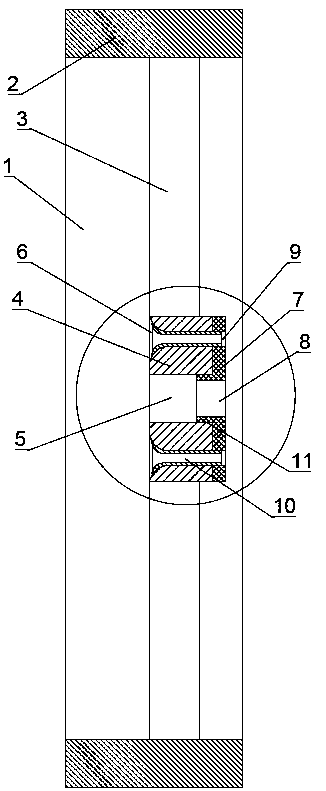

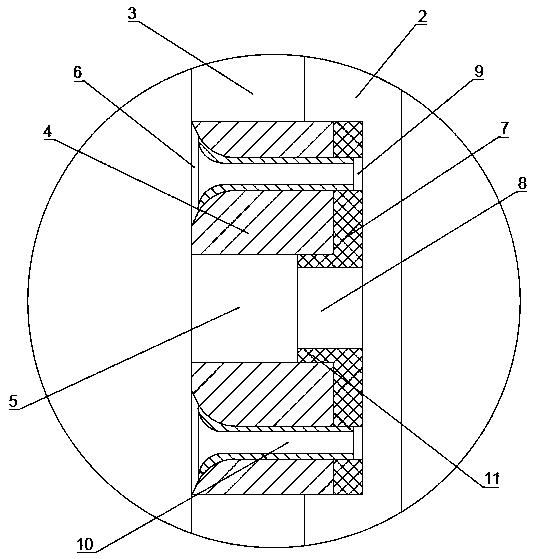

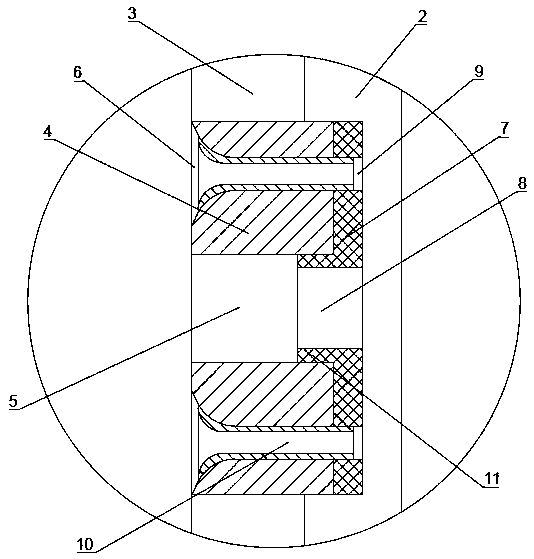

[0013] Such as figure 1 , figure 2 As shown, the center plate mounting surface structure of a carbon fiber hub described in this embodiment includes a hub body 1. The hub body 1 includes a rim 2, a spoke 3, and a center plate 4. The center of the hub body 1 is the center plate 4. A central hole 5 is provided in the center of the middle plate 4, and a PCD hole 6 is provided on the middle plate 4 on the periphery of the central hole 5. One of the axial sides of the middle plate 4 is a mounting surface, and an aluminum alloy is attached to the mounting surface Disk surface 7, the aluminum alloy disk surface 7 is provided with a first hole 8 corresponding to the center hole 5 of the middle disk 4, and the aluminum alloy disk surface 7 on the periphery of the first hole 8 is provided with a PCD hole 6 corresponding to the middle disk 4 No. 2 hole 9, and the No. 1 hole 8 on the side of the aluminum alloy disc surface 7 that is attached to the middle plate 4 is formed with an annular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com