Crude oil tank

An oil tank and crude oil technology, applied in containers, mixers, large containers, etc., can solve the problems of low heating efficiency, multi-fuel, and high cost, and meet the requirements of improving practicability, reducing temperature loss, and ensuring the flow performance of crude oil. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

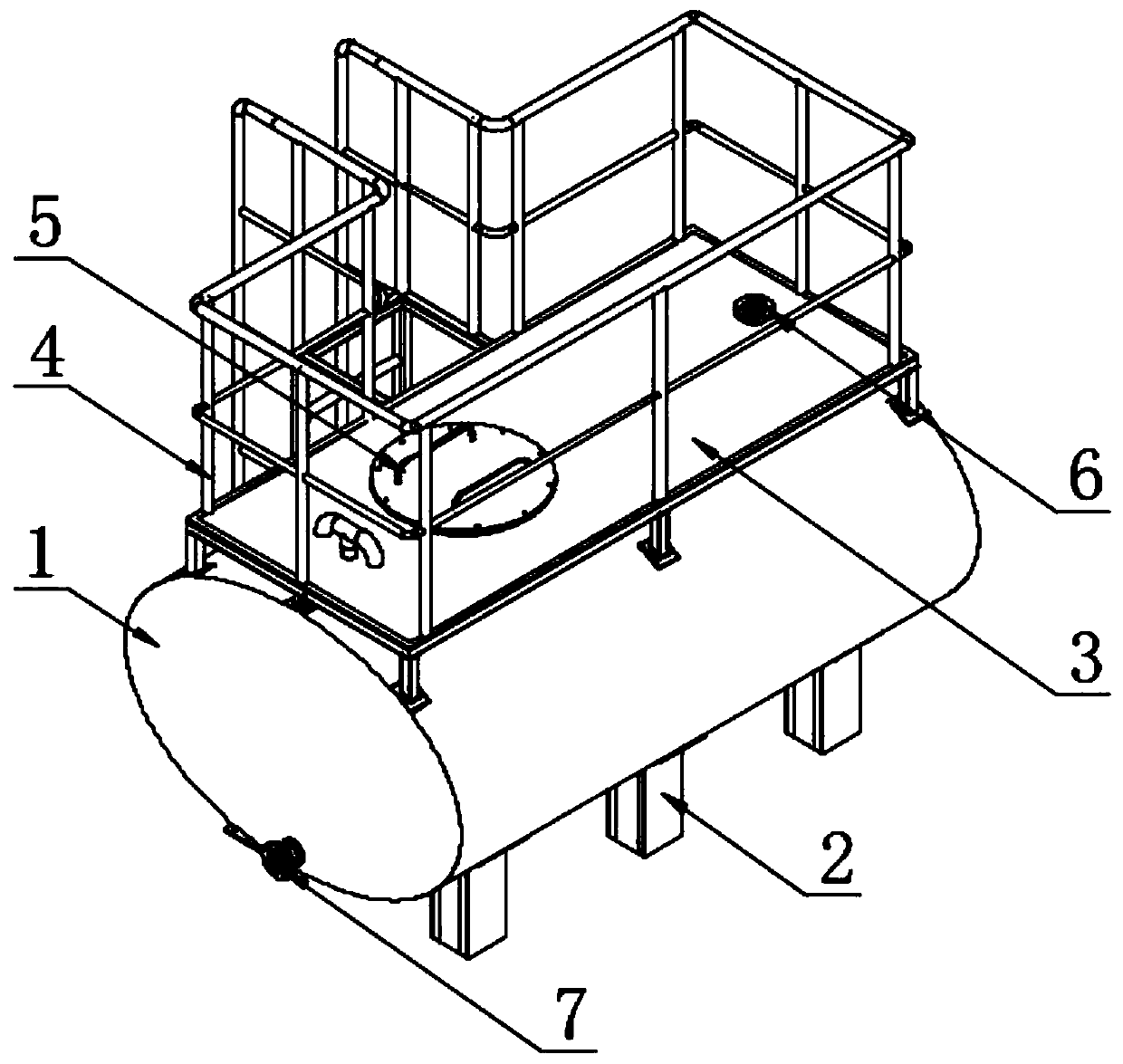

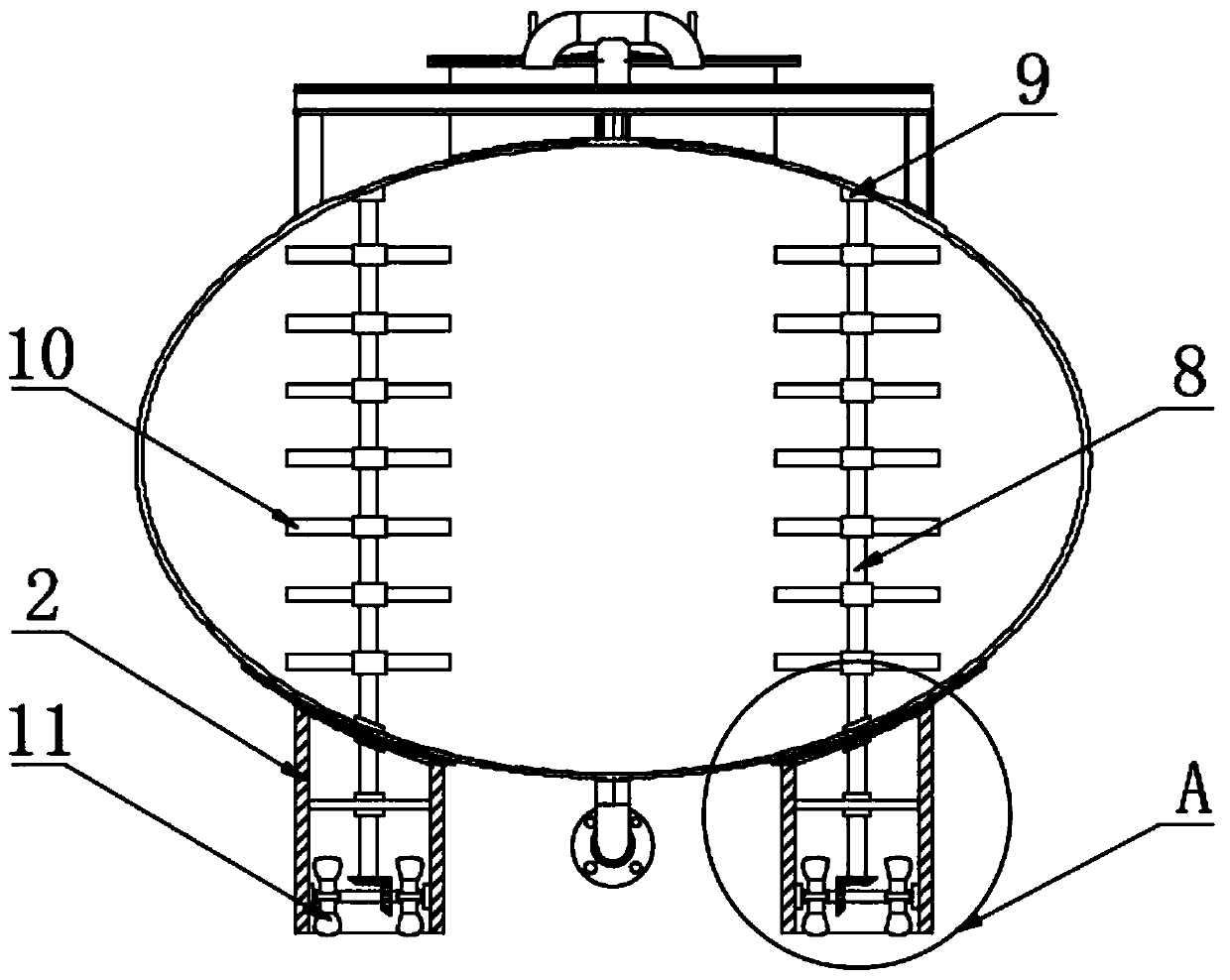

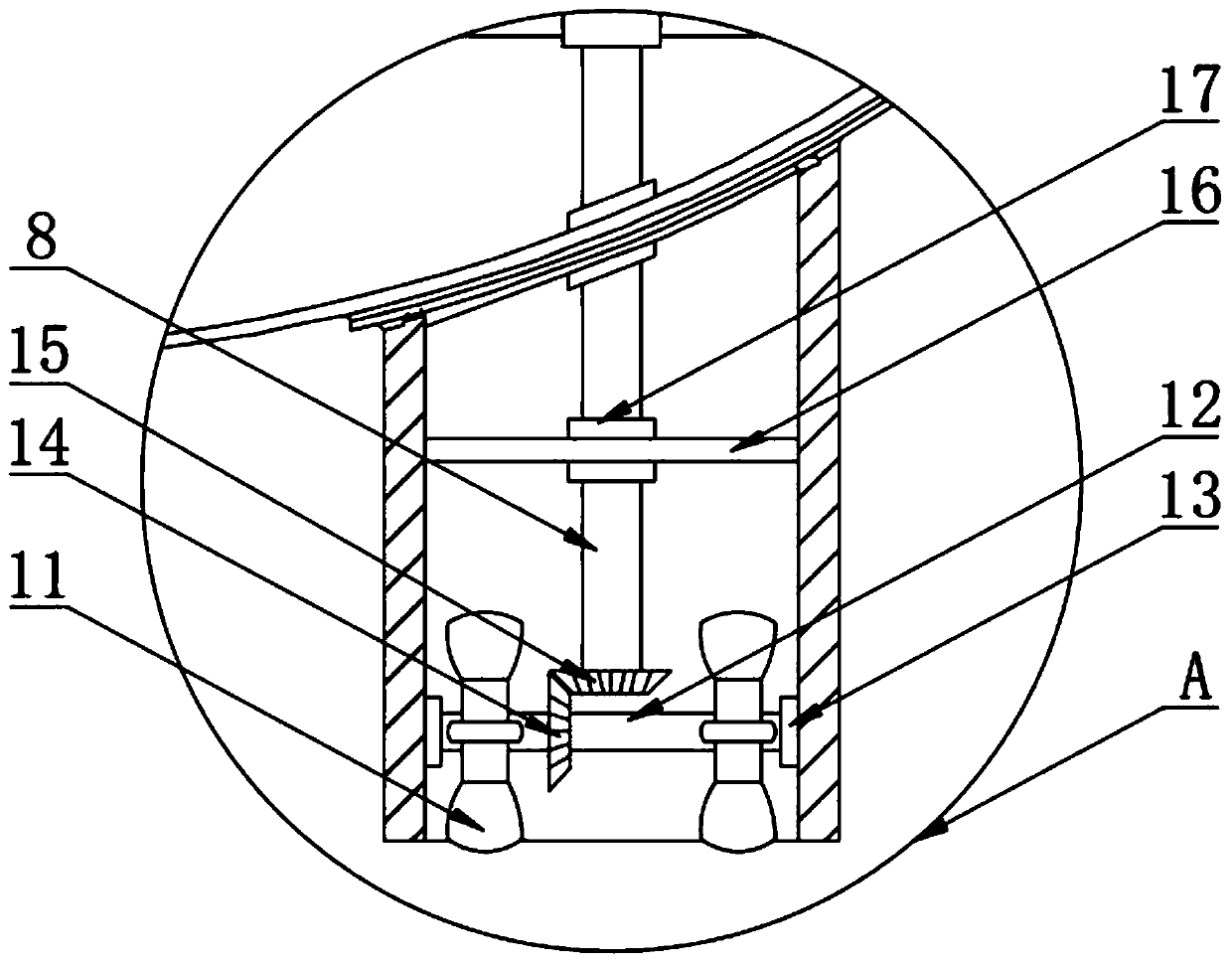

[0020] like figure 1 As shown, the present invention includes an oil tank main body 1, a plurality of sets of stirring mechanisms 2 are fixedly installed on both sides of the bottom end of the oil tank main body 1, and a top plate 3 is fixedly installed on the top of the oil tank main body 1, and the upper surface edge of the top plate 3 is fixed A protective fence 4 is installed to effectively ensure the safety of staff. An inspection cover 5 is fixedly installed on the top of the oil tank main body 1 near the side of the guardrail 4, and an oil inlet 6 is fixedly installed on the top of the oil tank main body 1 near the side of the inspection cover 5, and the inspection cover 5 and the oil inlet 6 Through the interior of the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com