Composite antibacterial film and preparation method thereof

A compound antibacterial and film liquid technology, applied in the field of food preservation, can solve the problems of no antibacterial effect and limited shelf life extension effect, and achieve good antibacterial effect, good antibacterial effect, and enhanced antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

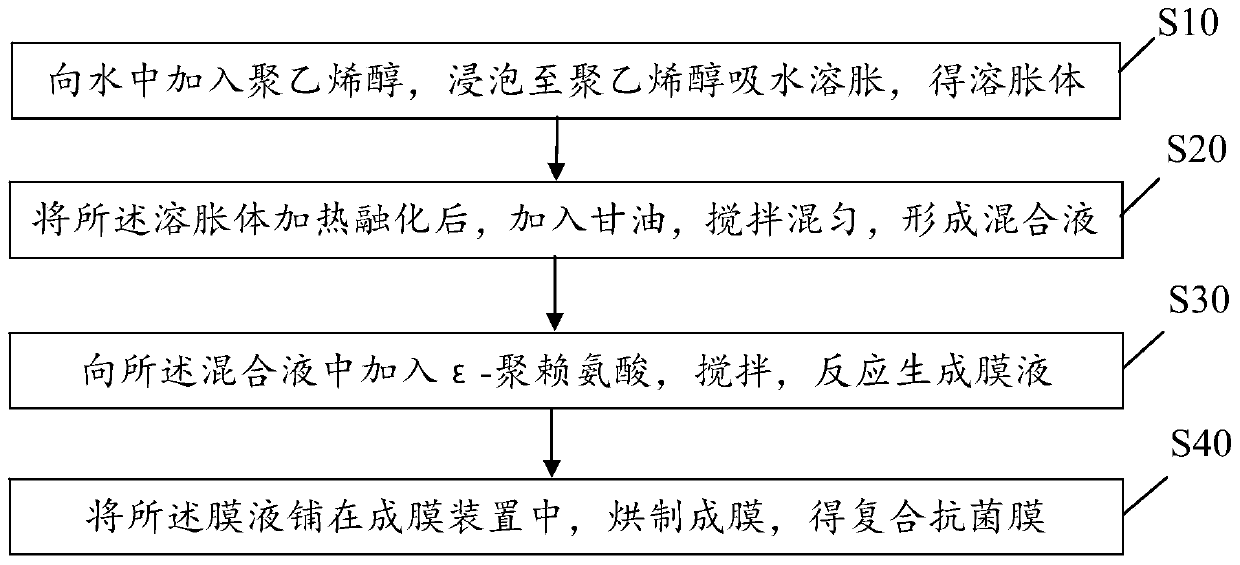

[0029] The present invention also proposes a method for preparing a composite antibacterial film, which is used for preparing the above composite antibacterial film. figure 1 It is an embodiment of the preparation method of the composite antibacterial film of the present invention.

[0030] refer to figure 1 , the preparation method of composite antibacterial film comprises the following steps:

[0031] Step S10, adding polyvinyl alcohol into the water, soaking until the polyvinyl alcohol absorbs water and swells to obtain a swollen body.

[0032] In this embodiment, polyvinyl alcohol and water are mixed according to the ratio of g:mL=1-3:100, and then soaked until the polyvinyl alcohol fully absorbs water and swells. Specifically, the soaking time is 1-3 hours.

[0033] Step S20, heating and melting the swollen body, adding glycerin, stirring and mixing to form a mixed liquid.

[0034] In specific implementation, the polyvinyl alcohol particles swelled by water absorption...

Embodiment 1

[0046] Weigh 3g polyvinyl alcohol into 100mL distilled water and soak for 1.7h, then place the polyvinyl alcohol particles swollen by water absorption in a boiling water bath and heat for 30min until completely melted, add 0.5g glycerin, stir magnetically for 20min, add 1gε-polylysine Acid, magnetically stirred for 20 minutes, put into an ultrasonic instrument for defoaming for 40 minutes, and obtained a membrane solution. Spread the film solution in a film forming device, bake at 30°C for 11 hours, then raise the temperature to 50°C, bake for 4 hours, and peel off the film to obtain a polyvinyl alcohol / ε-polylysine composite antibacterial film.

Embodiment 2

[0048] Weigh 1g polyvinyl alcohol and add it to 100mL distilled water to soak for 2h, then place the water-swellable polyvinyl alcohol particles in a boiling water bath and heat for 35min until completely melted, add 1g glycerin, stir magnetically for 40min, add 2gε-polylysine, Magnetically stirred for 40 minutes, put into an ultrasonic instrument for defoaming for 33 minutes, and obtained a casting solution. Spread the film solution in a film forming device, bake at 20°C for 13 hours, then raise the temperature to 40°C, bake for 4.2 hours, and peel off the film to obtain a polyvinyl alcohol / ε-polylysine composite antibacterial film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com