Dishwashing liquid capable of efficiently removing grease and preparation method thereof

A technology of detergent and grease, which is applied in the field of daily chemical washing, can solve the problems of inconvenience, affecting the user experience of the effect of detergent, and the slight cleaning effect of solid grease, so as to achieve the effect of improving the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

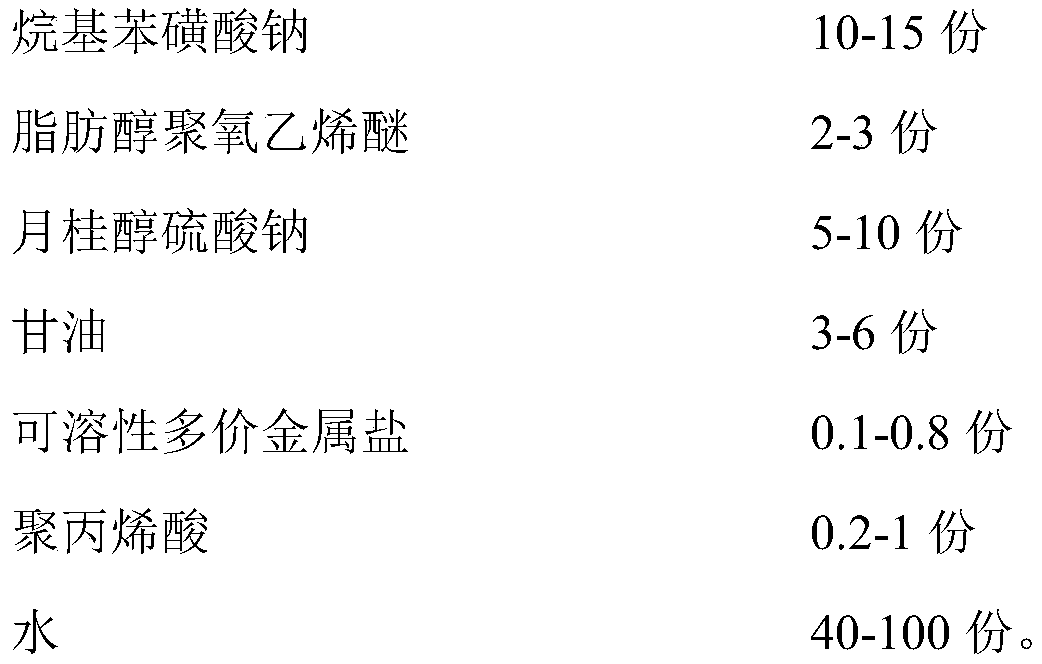

[0029] A dishwashing liquid for efficiently removing grease, comprising the following ingredients in parts by mass:

[0030]

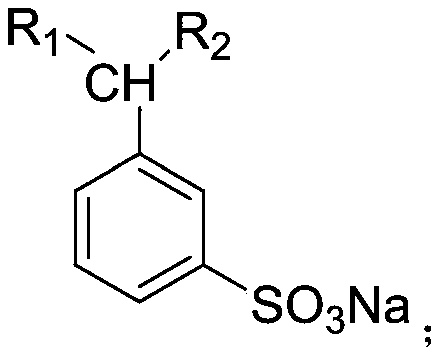

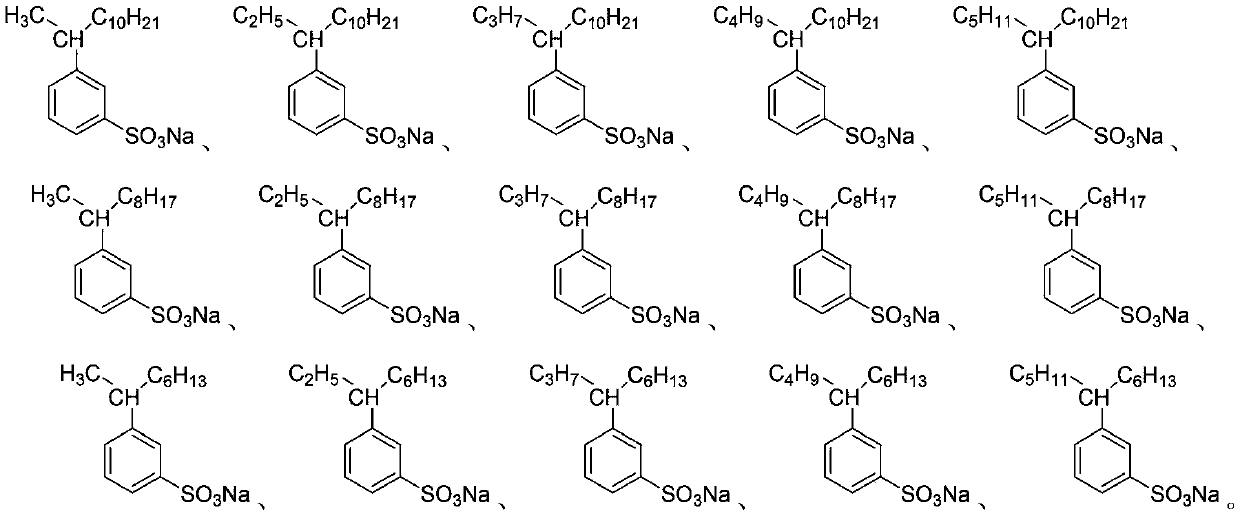

[0031] Wherein, sodium alkylbenzene sulfonate has the following structural formula:

[0032]

[0033] The molecular weight of polyacrylamide is 5000.

[0034] The preparation method of the above-mentioned highly efficient detergent for removing grease comprises the following steps:

[0035] S1. add water in reactor, then sodium alkylbenzene sulfonate, magnesium chloride, polyacrylic acid of above-mentioned structure are added, and stir;

[0036] S2. Add the rest of the ingredients and stir evenly.

[0037] Further, the stirring temperature in S1 is 40°C.

[0038] Further, the stirring speed in S1 is 100 rpm.

[0039] Further, the stirring speed in S2 is 100rpm.

Embodiment 2

[0041] A dishwashing liquid for efficiently removing grease, comprising the following ingredients in parts by mass:

[0042]

[0043]

[0044] Wherein, sodium alkylbenzene sulfonate has the following structural formula:

[0045]

[0046] The molecular weight of polyacrylamide is 20000.

[0047] The preparation method of the above-mentioned highly efficient detergent for removing grease comprises the following steps:

[0048] S1. add water in reactor, then sodium alkylbenzene sulfonate, calcium chloride, polyacrylic acid of above-mentioned structure are added, and stir;

[0049] S2. Add the rest of the ingredients and stir evenly.

[0050] Further, the stirring temperature in S1 is 60°C.

[0051]Further, the stirring speed in S1 is 300rpm.

[0052] Further, the stirring speed in S2 is 300rpm.

Embodiment 3

[0054] A dishwashing liquid for efficiently removing grease, comprising the following ingredients in parts by mass:

[0055]

[0056] Wherein, sodium alkylbenzene sulfonate has the following structural formula:

[0057]

[0058] The molecular weight of polyacrylamide is 15000.

[0059] The preparation method of the above-mentioned highly efficient detergent for removing grease comprises the following steps:

[0060] S1. add water in reactor, then sodium alkylbenzene sulfonate, tin chloride, polyacrylic acid of above-mentioned structure are added, and stir;

[0061] S2. Add the rest of the ingredients and stir evenly.

[0062] Further, the stirring temperature in S1 is 50°C.

[0063] Further, the stirring speed in S1 is 200rpm.

[0064] Further, the stirring speed in S2 is 200rpm.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap