Flavoring fermented grain distillation component for brewing Luzhou-flavor liquor

A technology for strong-flavor liquor and fermented grains, applied in the field of winemaking, can solve the problems of inability to discharge low-concentration and inferior alcohol separately, inability to classify alcohol, and inability to steam out alcohol, etc., and achieves ingenious structure, high degree of automation, and operation. Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

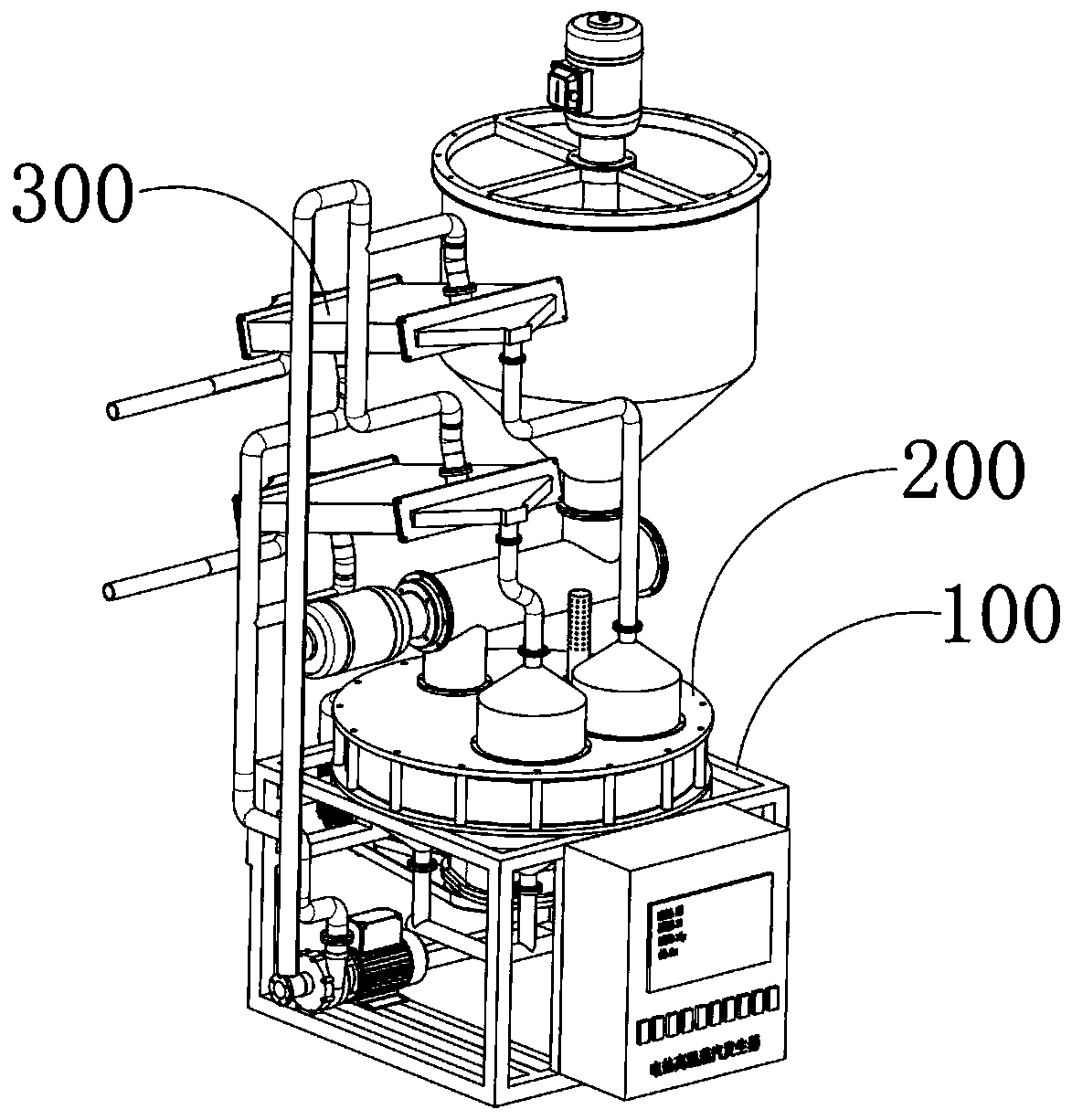

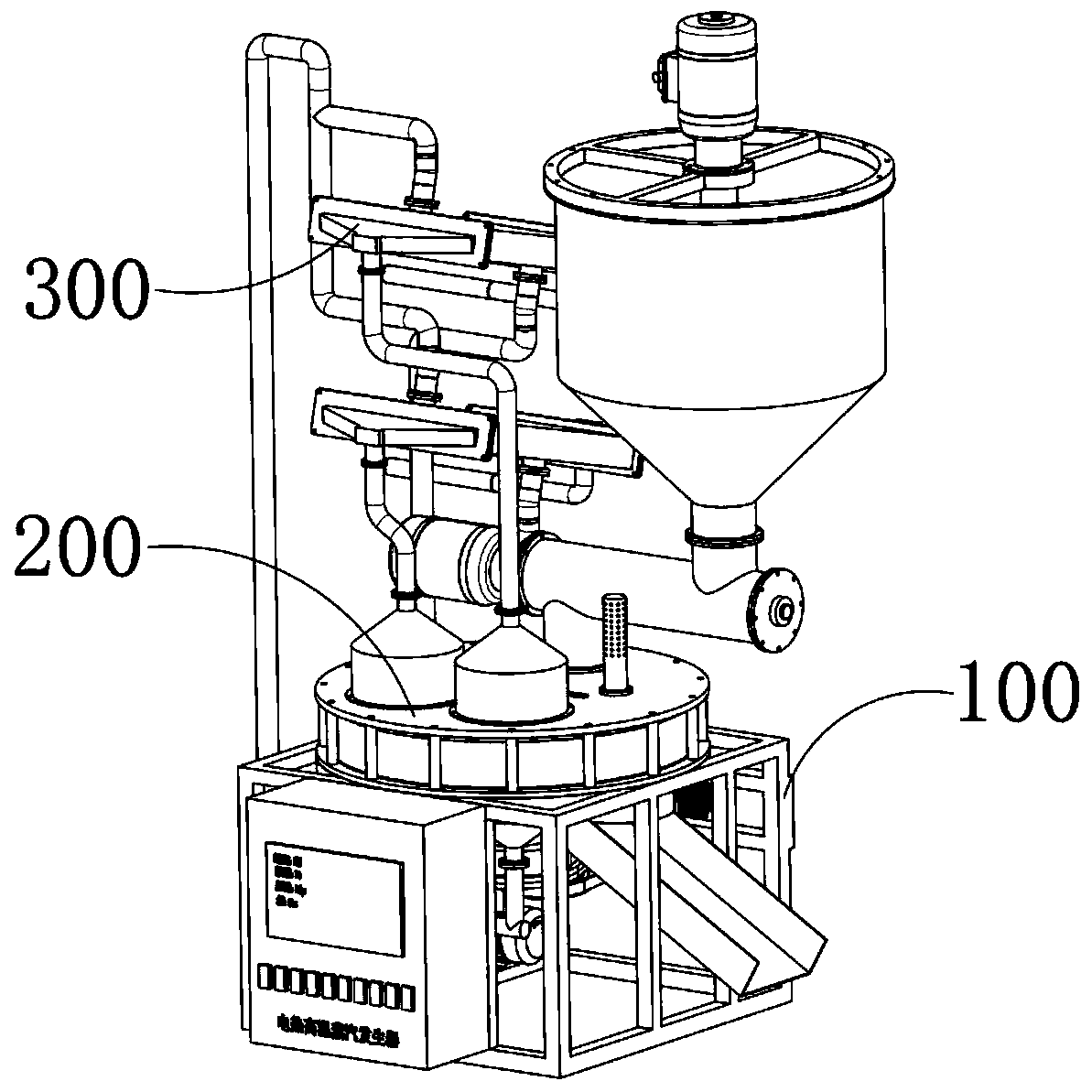

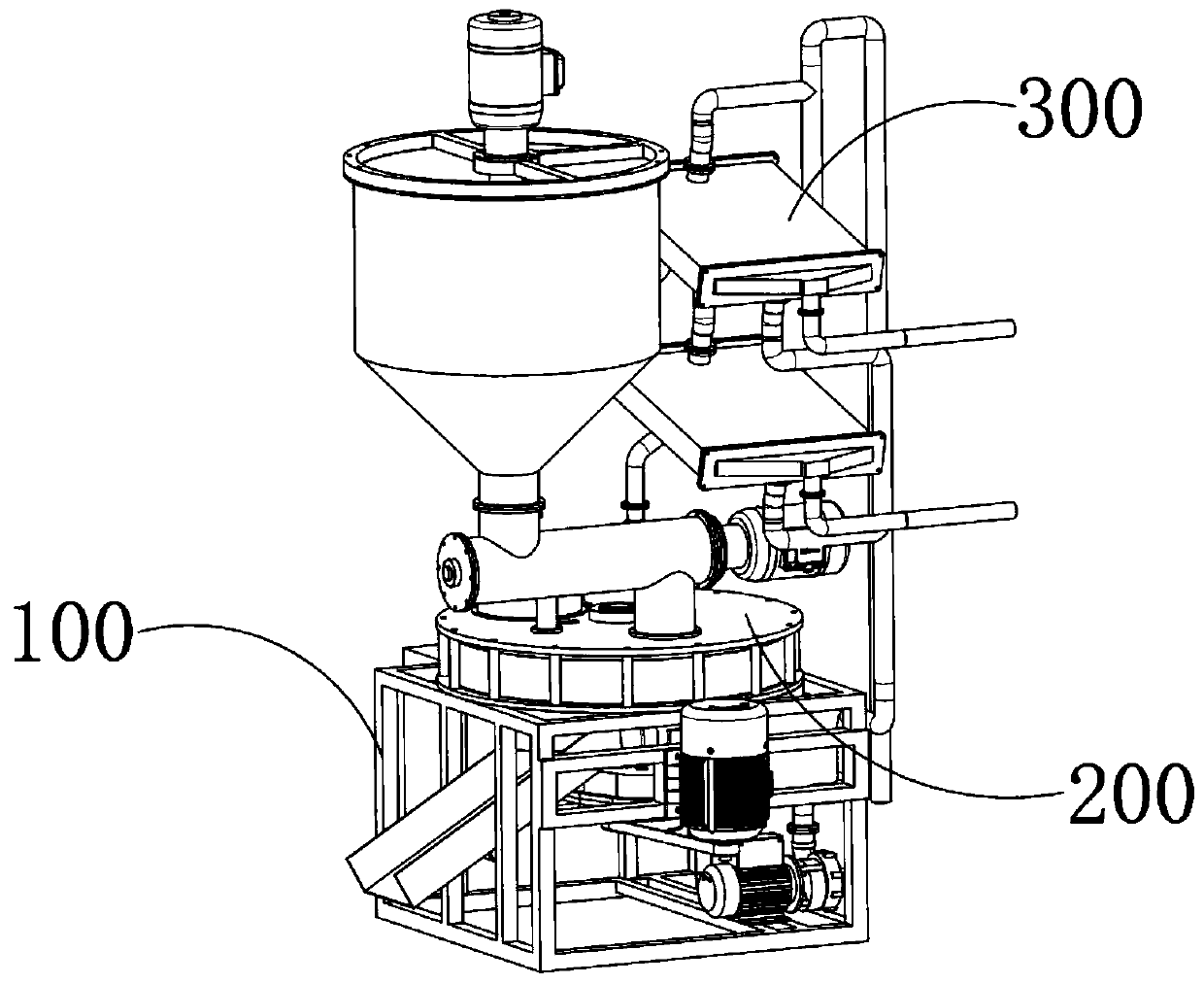

[0050] see Figure 1-26 , an alcohol distiller for circulating graded brewing, which includes a mounting frame 100, a distillation device 200 and a cooling device 300, the distillation device 200 and the cooling device 300 are fixedly installed on the mounting frame 100, wherein the distillation device 200 includes a plurality of The distiller body 210, the rotary drive mechanism 220, the steam generator 230 and the feeding mechanism 240 of the storage tank 214b, the storage tank 214b is arranged in an array in the circumferential direction and can be driven by the rotary drive mechanism 220 to perform a gradual rotary motion, and the gradual rotation The storage tank 214b can be connected to the output end of the feeding mechanism 240 in turn and accept the fermented grains supplied by the feeding mechanism 240. The storage tank 214b after adding the fermented grains can be connected to the output end of the steam generator 230, and the steam will be generated. The device 230...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com