Ultra-high performance concrete prefabricated assembly comprehensive pipe rack

A comprehensive pipe gallery and ultra-high-performance technology, applied in protection devices, water conservancy projects, artificial islands, etc., can solve the problems of poor waterproof effect of assembly joints, inconvenient assembly and transportation, and low assembly accuracy, so as to reduce the number of connections and The effect of reducing the number of potential leakage points, reducing the use time of foundation pits, and reducing construction risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

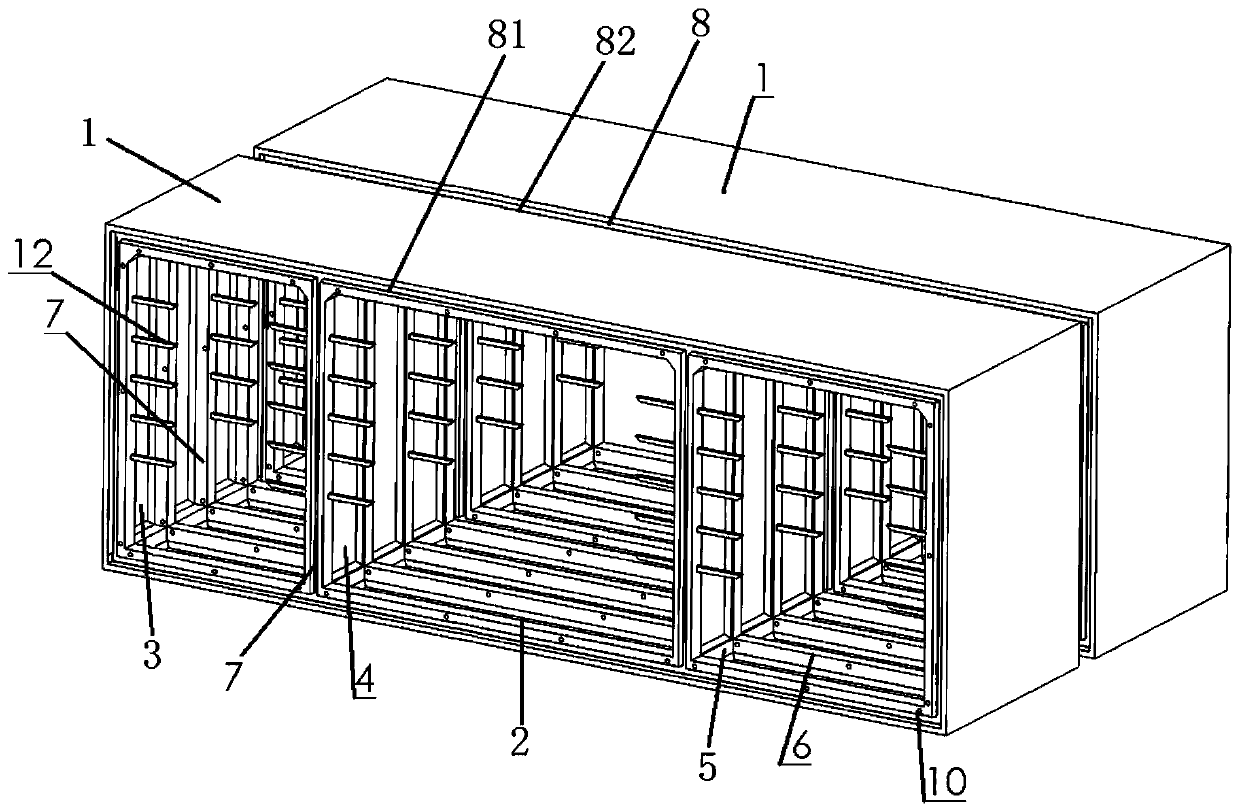

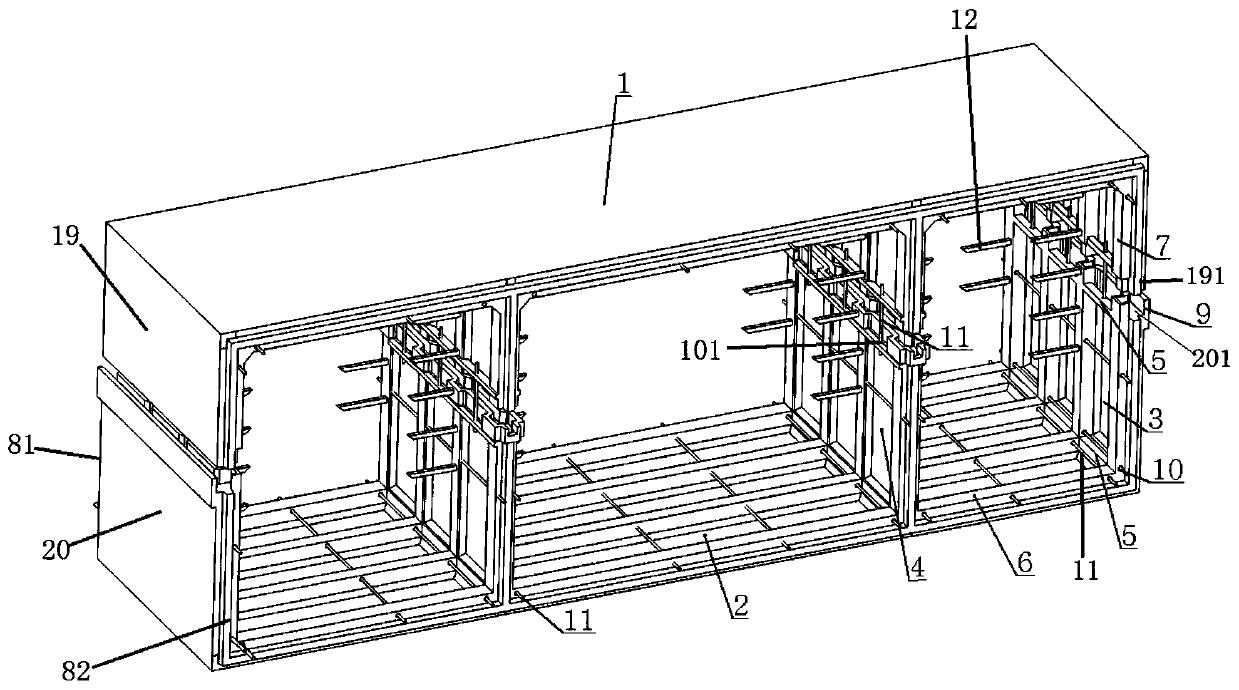

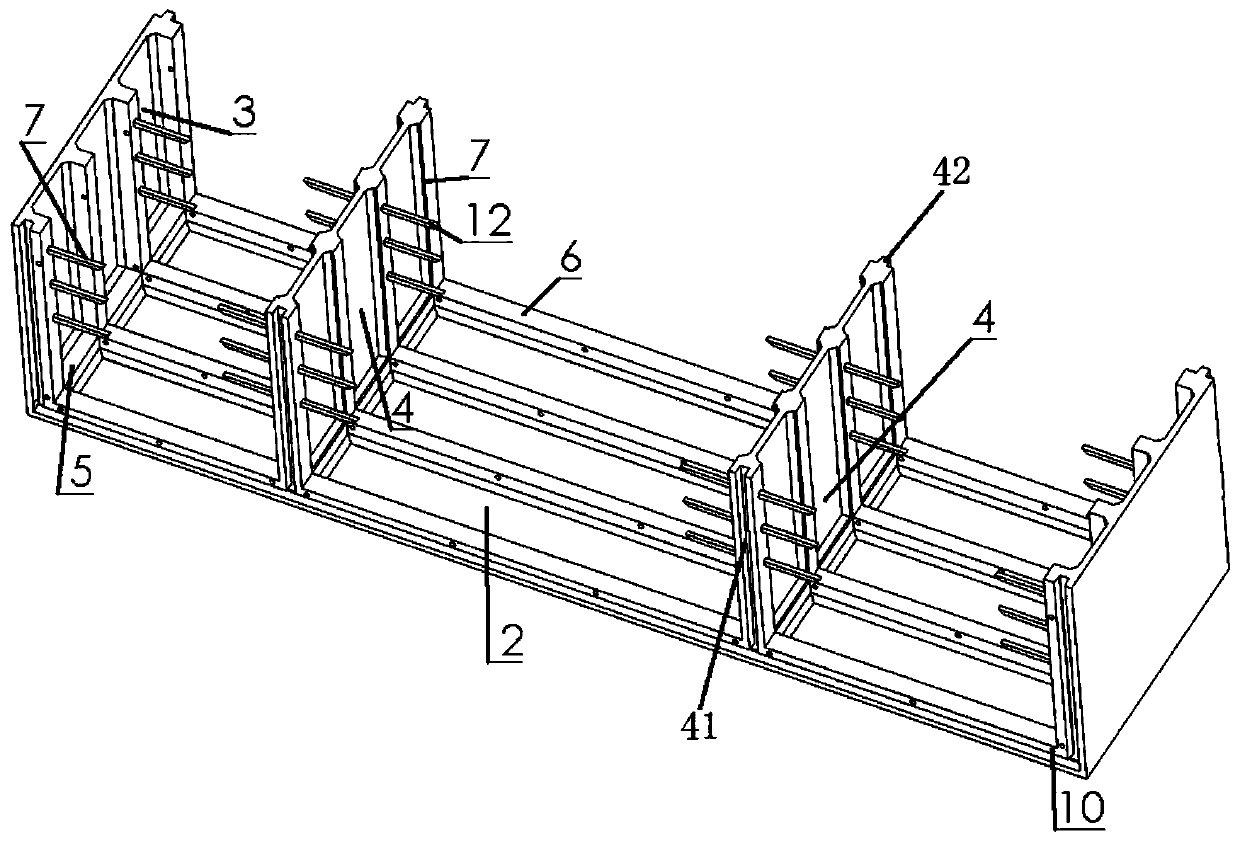

[0078] For a pipe gallery project, the length of the pipe gallery is about 1km, and the length of one of the ultra-high performance concrete prefabricated integrated pipe gallery is about 500m. The pipe corridor has a total width of 9.5 meters and a total height of 3.5 meters. It is a single-box three-room structure, and the cabins are respectively power cabin + water signal cabin + power cabin.

[0079] The pipe gallery is prefabricated and assembled with ultra-high performance concrete. A single section is 4 meters long and 9.5 meters wide. The thickness of the top plate 1, the bottom plate 2, the outer vertical plate 3 and the middle vertical plate 4 are all 0.06 meters; the longitudinal beam 5 is set between the top plate 1, the bottom plate 2 and the vertical plate, which is integrally poured with the same plate, the height is 0.35 meters, and the thickness is 0.35 meters. 0.40 meters; the top and bottom plates 2 are provided with a beam 6 every 0.75 meters, the height of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com