Mould plate for forming groove of inspection chamber

A technology for stereotyped templates and inspection wells, which is applied to waterway systems, sewer systems, drainage structures, etc., can solve the problem of low mold versatility, and achieve the effect of improving mold versatility and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

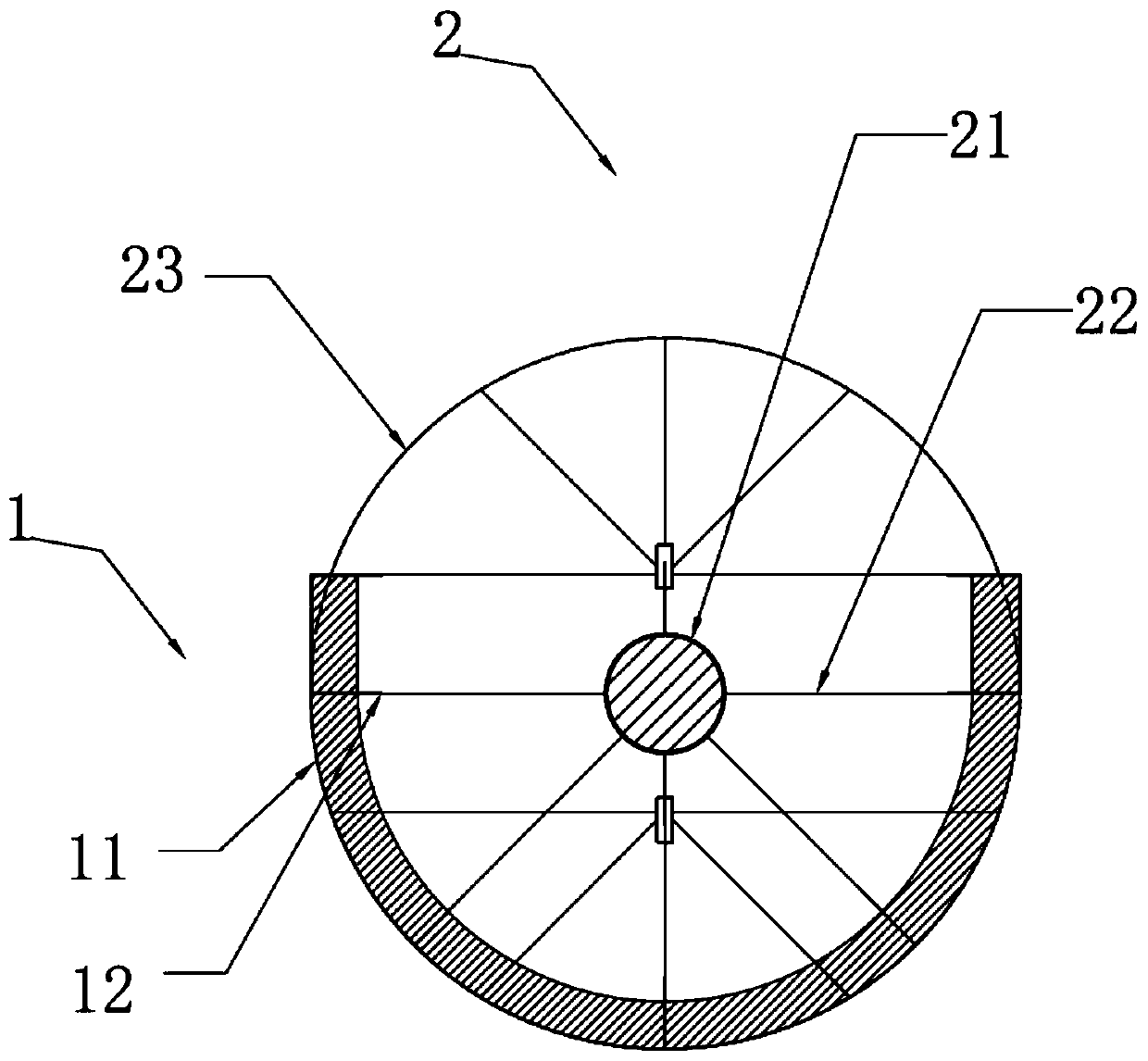

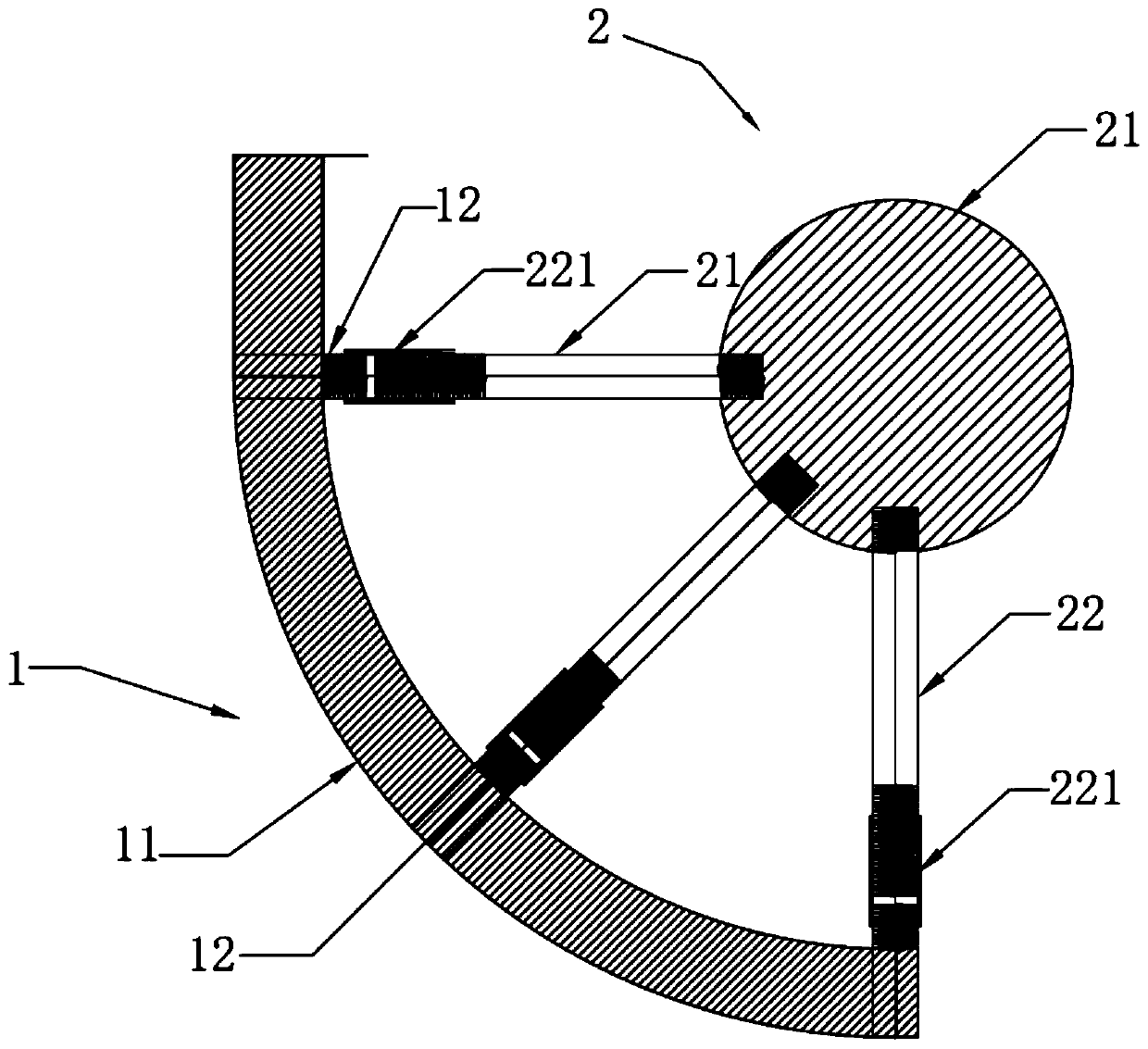

[0033] figure 1 It is a schematic cross-sectional view of the local structure of the shaped template of the inspection well launder in the embodiment of the present invention, as figure 1 As shown, in this embodiment, the inspection well launder shaping template includes a mold assembly 1 that can be matched and combined according to the launder type. According to different inspection well types, the launder types are also different, such as rainwater inspection wells and sewage The width of the top of the corresponding chute is designed differently for inspection wells; for two-way inspection wells, three-way inspection wells, and four-way inspection wells of different sizes, the bending radius of the corresponding launder turns is also different. The shape of the mold assembly 1 is a unified standardized shape formed according to the different types, pipe diameters, angles, etc. of the launder. The standardization here refers to the conventional dimensions stipulated in the ...

Embodiment 1

[0051] Figure 4 It is a schematic structural view of the shaped template of the inspection well launder in Embodiment 1 of the present invention, as Figure 4 As shown, the nominal diameter of the drainage pipe in the inspection well is DN300㎜, the chute of the inspection well is a linear chute, the bracket assembly 2 includes a central axis 21, and the mold assembly 1 is composed of two symmetrically combined arc-shaped panels. Other numbers of combination templates 11 can be used for splicing, and here only two of them are taken as an example for illustration, and no unique limitation is made.

[0052] Such as Figure 6 As shown, optionally, the thickness of each curved panel is 20mm, and the formwork column flute 12 embedded on each curved panel is a cylinder with a diameter of 10mm and a total length of 30mm, wherein the formwork column flute 12 faces The height of the convex part inside the curved surface is 10 mm. The diameter of the central axis 21 is preferably 80 ...

Embodiment 2

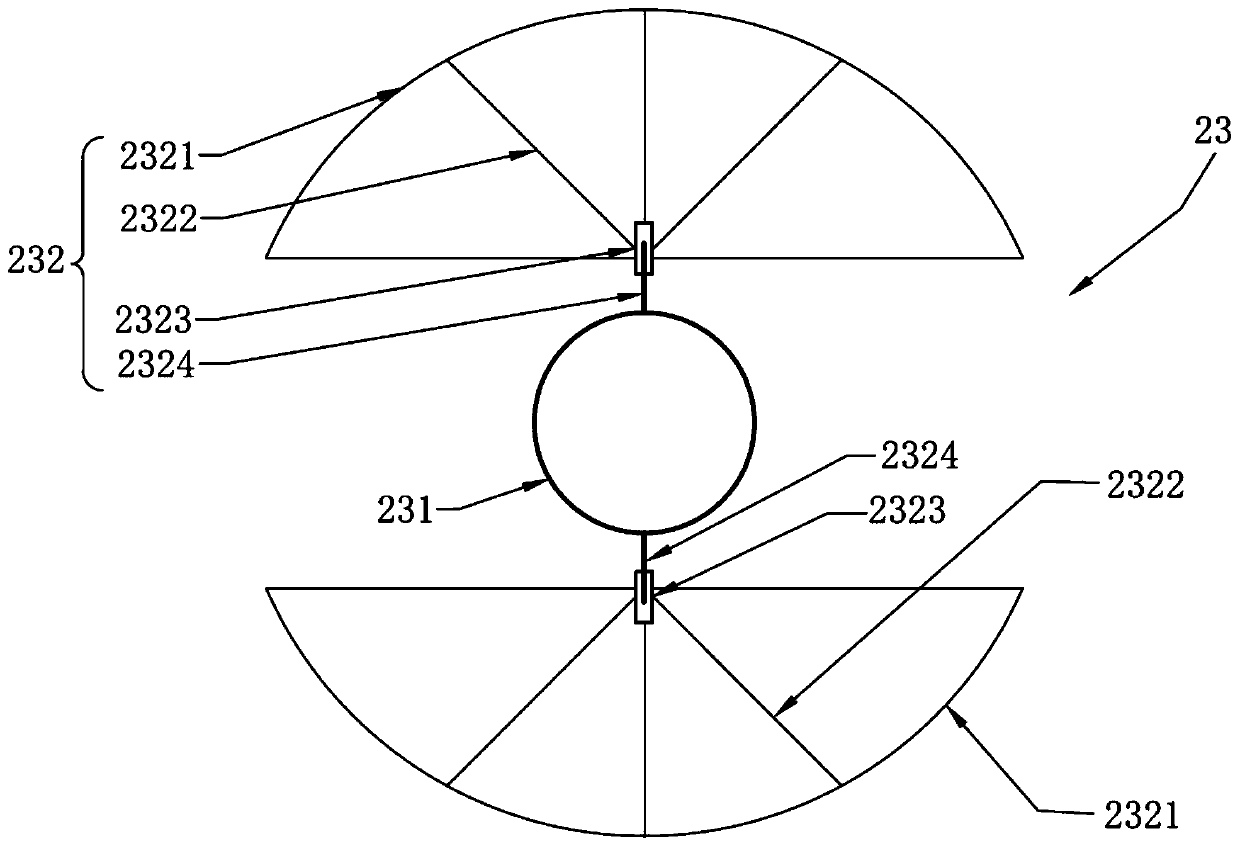

[0058] Such as Figure 7 As shown, in this embodiment, the nominal diameter of the drainage pipe in the inspection well is DN300mm, and the launder in the inspection well is a 90° three-way launder. Compared with Embodiment 1, the drainage pipe in the inspection well in this embodiment is composed of two water inlets and one water outlet converging, and the water inlet and water outlet intersect at 90°. The mold assembly 1 of the shaped template of the launder in this embodiment is composed of a plurality of combined templates 11, including a straight panel formed at the straight line of the launder and an arc-shaped panel formed at the turning of the launder. The bracket assembly 2 is provided with two central shafts 21, one long central shaft is supported by the shaft end jacking assembly 23 placed at the two water inlets, and one end of the short central shaft is supported by the shaft end jacking assembly placed at the water outlet. 23 supports, the other end of the short...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com