Steel-concrete composite beam

A technology of steel-concrete composite beams and H-beams, applied in structural elements, building components, building insulation materials, etc., to improve building quality, improve fire resistance and corrosion resistance, and facilitate later decoration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

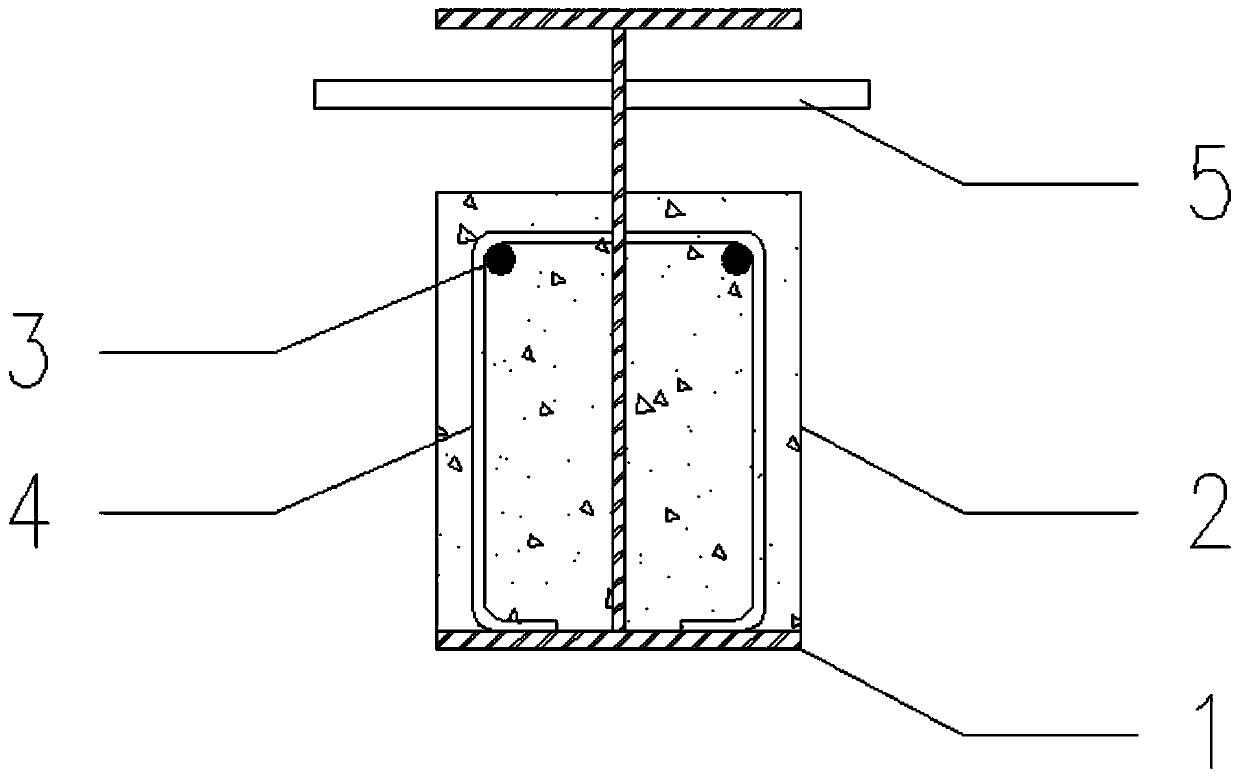

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

[0023] Such as figure 1 , figure 2 As shown, a steel-concrete composite beam includes H-shaped steel 1, concrete 2, and steel mesh set in concrete 1, the bottom of concrete 2 is closely attached to the bottom wing of H-shaped steel 1, and the two sides of concrete 2 are connected to the bottom wing of H-shaped steel 1. The edge of the plate is even, and there is a space between the top of the concrete 2 and the top flange of the H-shaped steel 1. One section of the middle web of the H-shaped steel 1 is buried in the concrete 2, and the other section is located in the space. The middle web of the H-shaped steel 1 is located in the space A section of the inner section is provided with a plurality of through holes that are isolated from each other and can accommodate steel bars to pass through;

[0024] H-shaped steel 1 is one of ordinary H-shaped steel, honeycomb H-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com