Blade fault monitoring method and equipment based on double arrays

A fault monitoring, dual-array technology, applied in mechanical equipment, wind turbine monitoring, wind power generation, etc., can solve problems such as difficulty in determining the location of blade faults, and achieve the effects of convenient deployment, cost reduction, and low delay.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

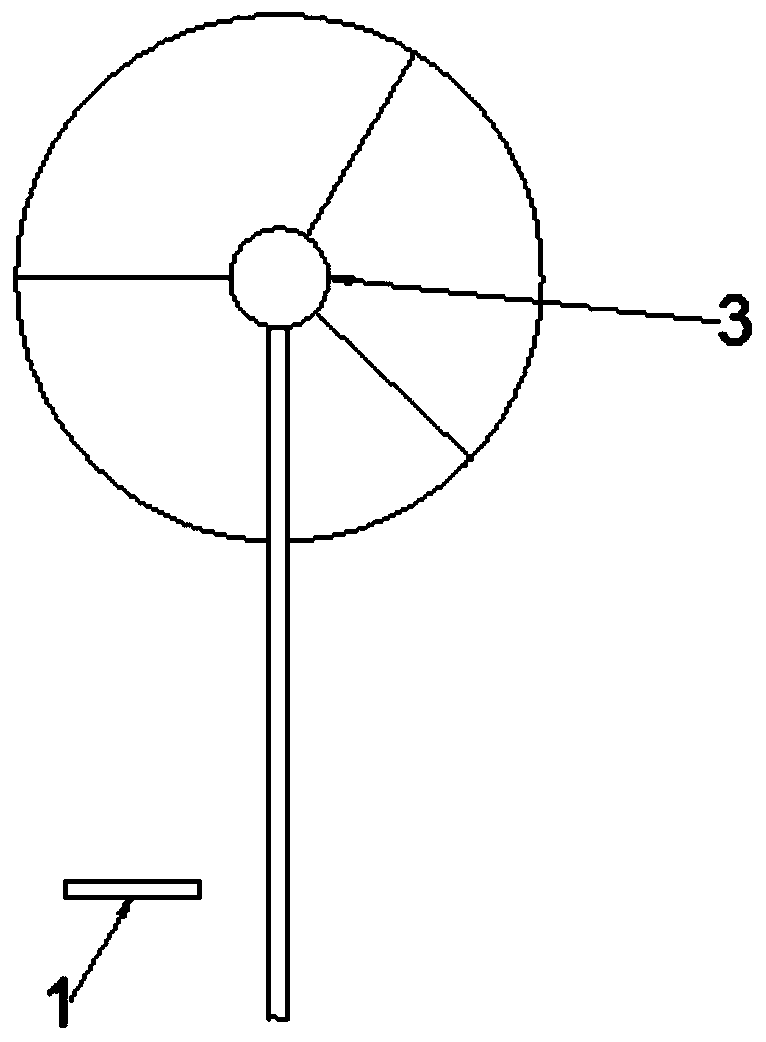

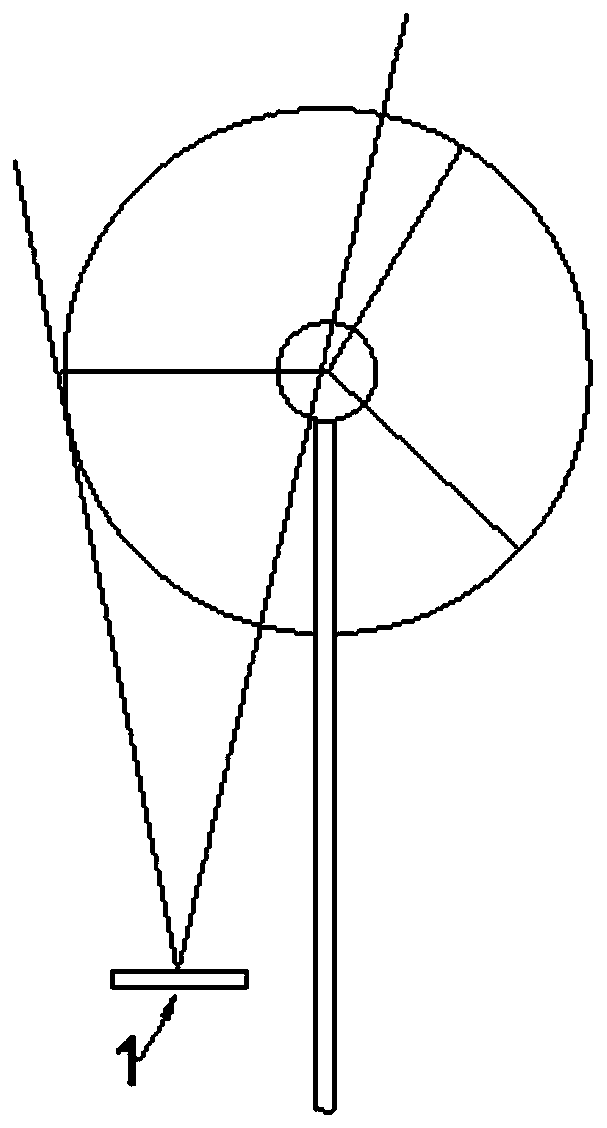

[0040] A blade failure monitoring method based on a double array, including a wind power generation tower, the wind power generation tower includes a tower body 3 and blades, the lower end of the tower body 3 is fixed on the ground, and the other end is connected to the blades through the tower tube, and the blades are connected by The plane on which the tower rotates as the axis is the fault plane 5, which includes the following steps:

[0041] S1. Arrange sound pick-up arrays to monitor and obtain blade fault information;

[0042] Set the position of the first array 1, specifically:

[0043] Such as figure 1 , figure 1 It is a side view of the position of the first array and the wind power generation tower in the present invention; the first array 1 is deployed at the bottom of the wind power generation tower. In this embodiment, the pick-up array is preferably arranged on the ground by means of bolts or the like, wherein,

[0044]The connection line between the end of th...

Embodiment 2

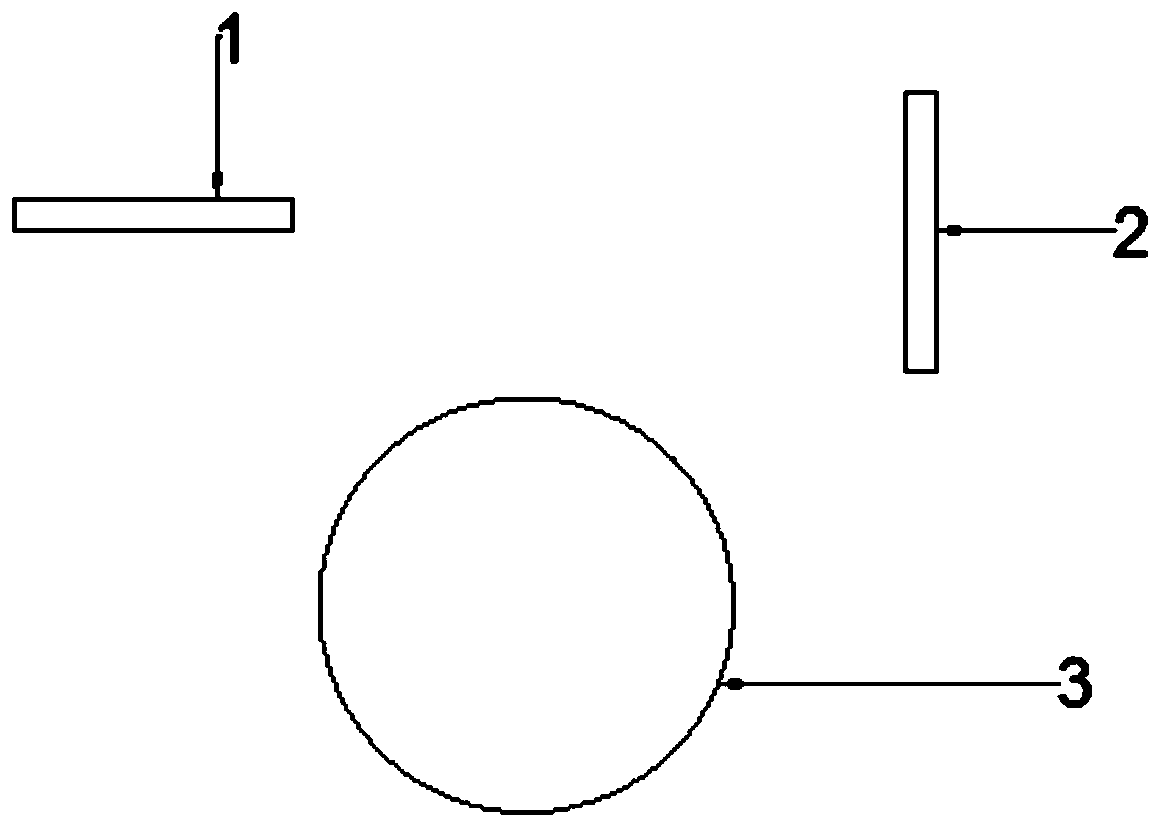

[0075] Such as figure 2 as shown, figure 2 It is a top view of the first array, the second array and the wind power tower; a blade failure monitoring device based on double arrays, including the first array 1, the second array 2 and the tower body 3, the first array 1 and the second Array 2 is deployed at the bottom of the wind power tower, and the pickup array can be arranged on the ground by means of bolts or the like;

[0076] Wherein, the connection line between the end of the first array 1 close to the tower body 3 and the center of the tower body 3 is larger than the radius of the tower body 3 in the direction parallel to the first array 1 body, which can be set according to the actual situation. The length of the projection, the length of the first projection is preferably within 2 times of the radius of the tower body 3, and in this embodiment, the distance of the first projection is 1.2 times of the radius of the tower body 3;

[0077] Further, the first array 1 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com