Leakage-proof detection device for valve machining

A leak-proof detection and valve technology, applied in measuring devices, by detecting the appearance of fluid at the leak point, mechanical valve testing, etc., can solve problems such as reducing the practicability of the device, failing to detect valve leaks, and not simulating water flow impact detection, etc. , to achieve the effect of improving the fixed effect and improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

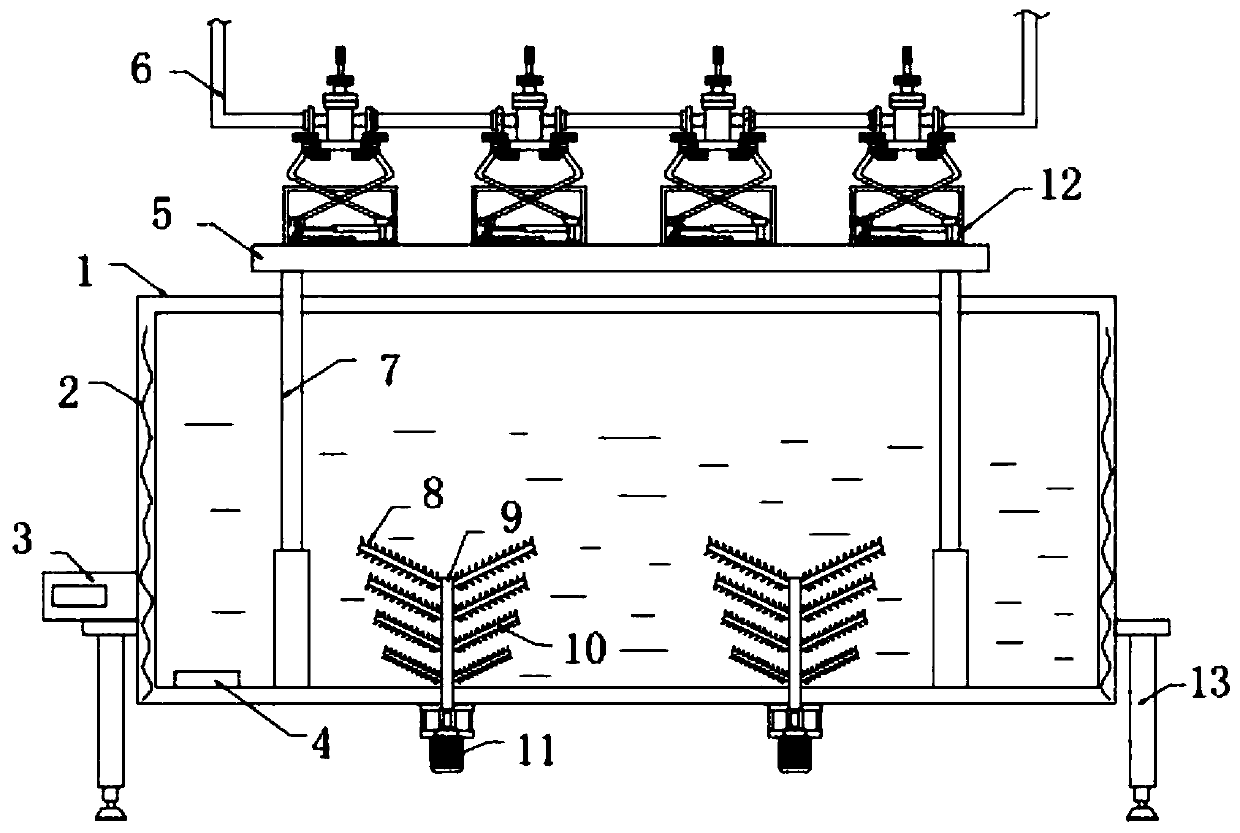

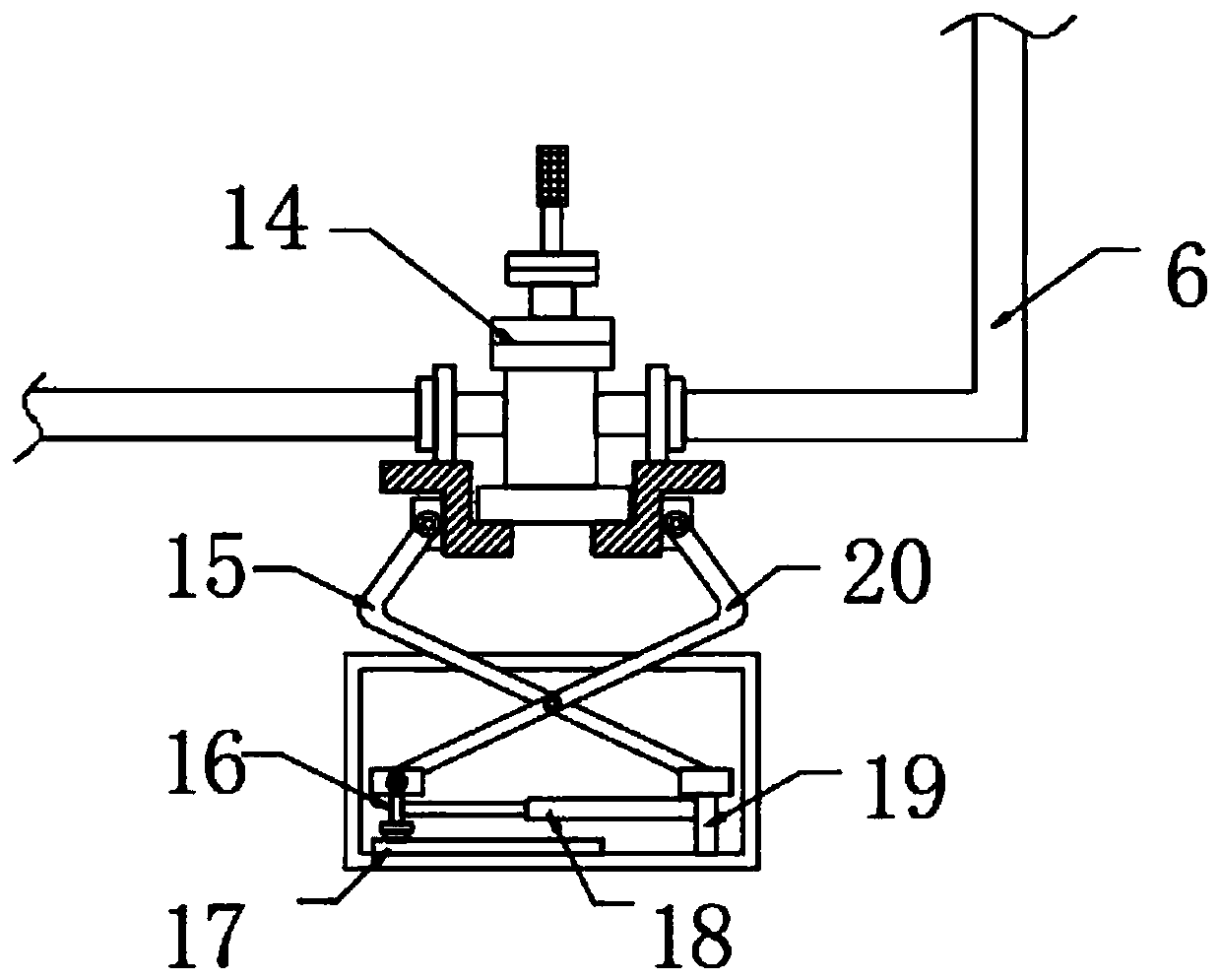

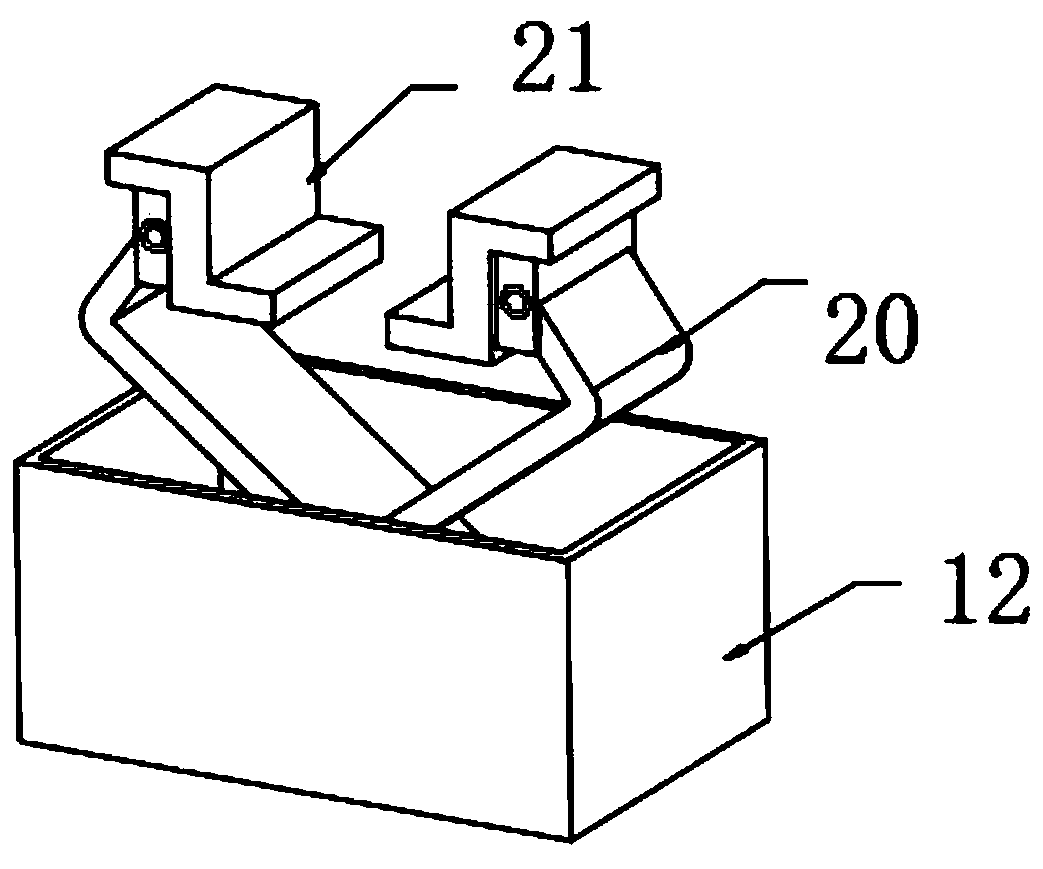

[0029] refer to Figure 1-4 , a leak-proof detection device for valve processing, including a transparent detection box 1, a motor 11 is fixed on both sides of the bottom outer wall of the transparent detection box 1 by screws, and the output shaft of the motor 11 is connected with a rotating rod 9 through a coupling , the two sides of the outer wall of the rotating rod 9 are welded with stirring rods 10 equidistantly distributed, and the specifications of the stirring rods 10 are different in size, and the size of the stirring rods 10 gradually decreases from top to bottom, forming an inverted trumpet-like structure, stirring The outer wall of the rod 10 is welded with equidistantly distributed stirring blades 8, and the size of the stirring blades 8 is different. The inner wall of the transparent detection box 1 is provided with a heating mechanism, and both sides of the bottom inner wall of the transparent detection box 1 are fixed by screws. The first hydraulic rod 7.

[...

Embodiment 2

[0037] refer to Figure 5 , a leak-proof detection device for valve processing, also includes a fixed rod 23 fixed on both sides of the inner wall of the transparent detection box 1 by screws, the other end of the fixed rod 23 is fixed with a baffle 22 by screws, and the baffle 22 is Arc structure.

[0038]Connect the equipment to the power supply, connect the first hydraulic rod 7 and the second hydraulic rod 18 to the hydraulic system respectively, adjust the length of the second hydraulic rod 18 according to the specifications of the valve body 14, and make the clamping plate 21 clamp the valve body 14 , connect the air guide tube 6 and the valve body 14 through the flange, adjust the length of the first hydraulic rod 7, make the valve enter the water, ventilate in the air guide tube 6, and wait to see if there are bubbles. If there are no bubbles, turn on the electric heater Wire 2, heat the valve body 14, observe whether the valve body 14 is leaking at high temperature, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com