A Fabric Elastic Recovery Tester Based on Double Test of Bracket Strengthening Data

A recovery tester and double-testing technology, applied in elastic testing, machine/structural components testing, instruments, etc., can solve problems such as poor adjustment of weaving strips, errors in data testing, and insufficient fixation of fabrics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

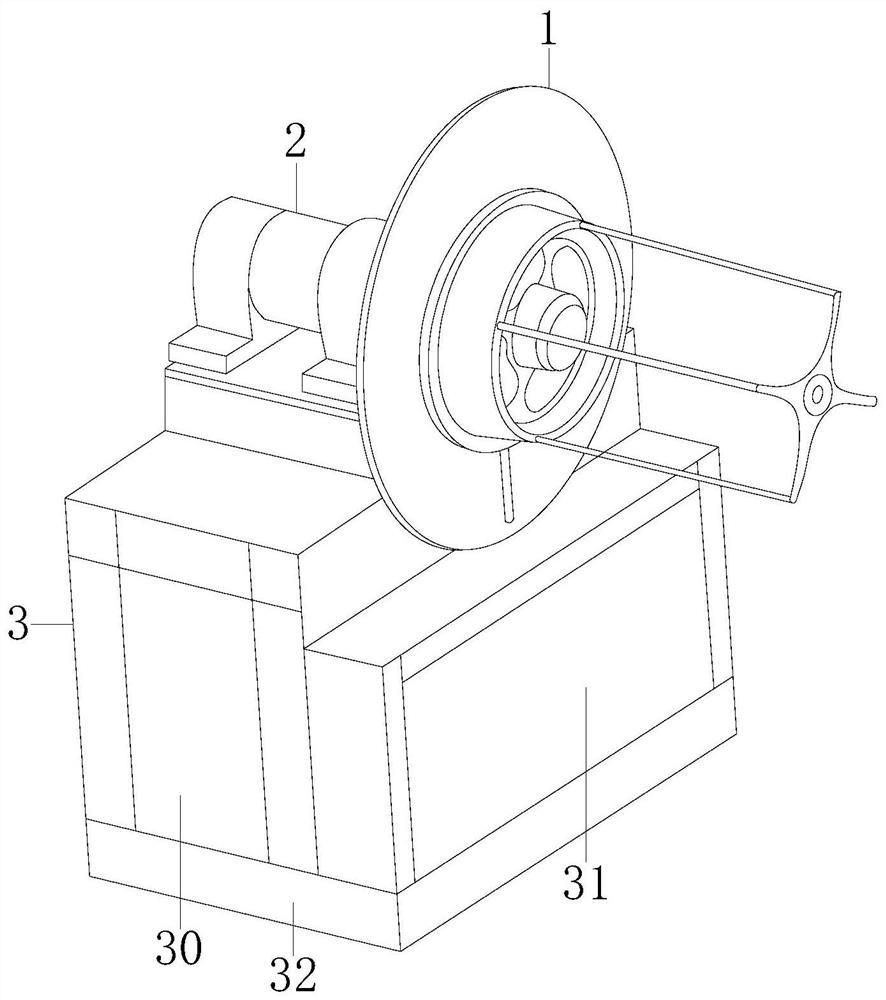

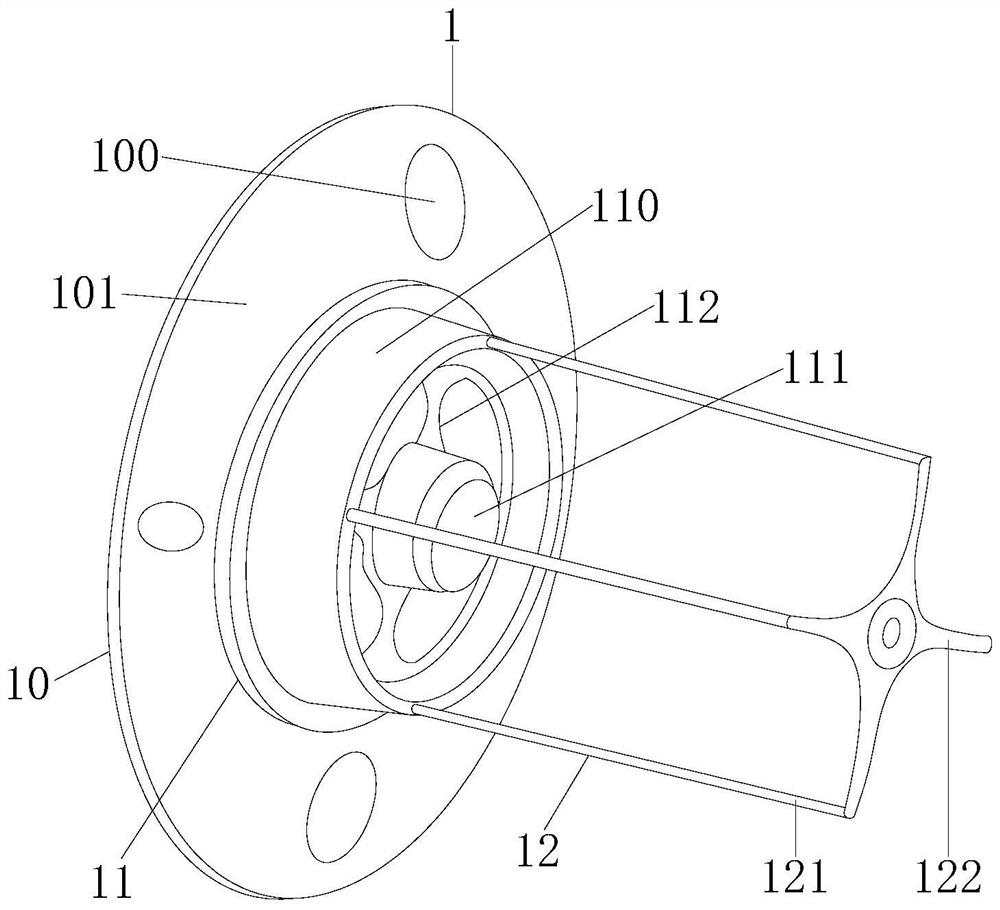

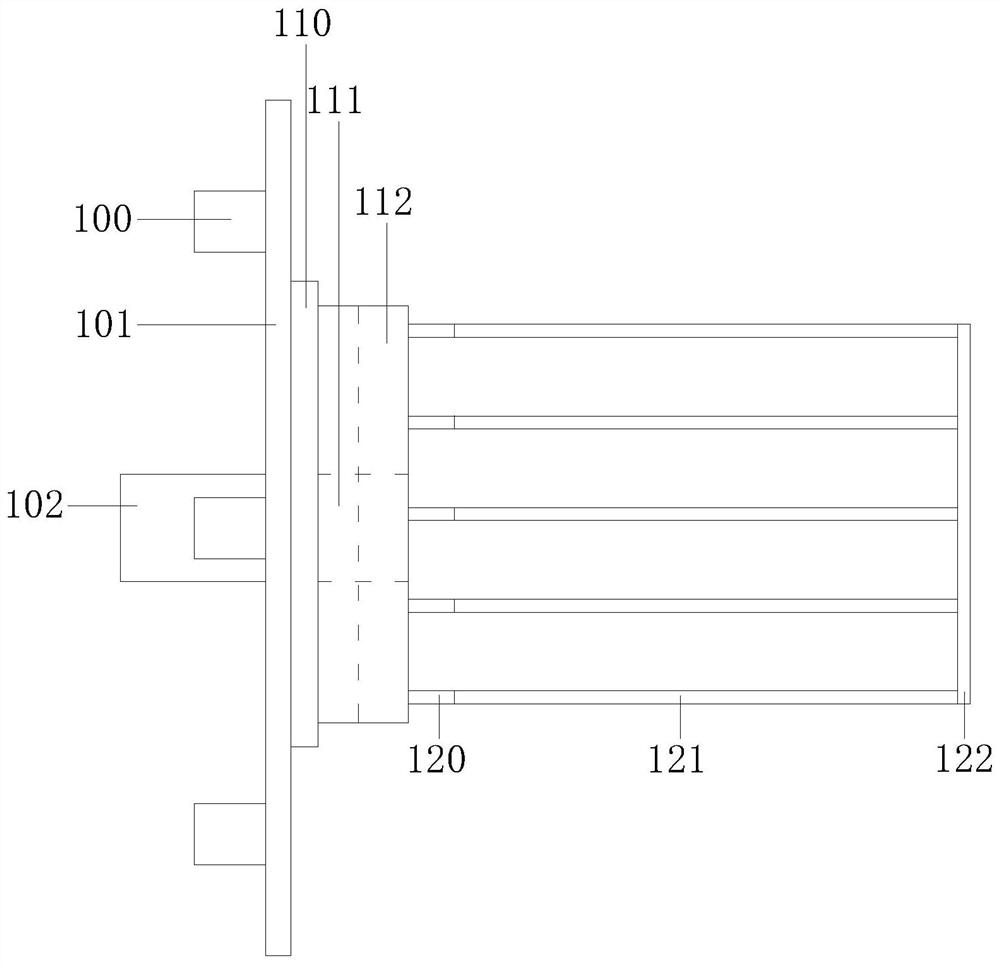

[0026] Example 1 see Figure 1-5 , the present invention provides a technical scheme of a fabric elastic recovery tester based on double testing of bracket reinforcement data: its structure includes a winding structure 1, a motor 2, and a base structure 3, the winding structure 1 is connected to the motor 2 shafts and two The motor 2 is locked with the base structure 3, and the base structure 3 is composed of a main base 30, a solid plate 31, and a bottom frame 32. The main base 30 has a heavy gravity for gravity reinforcement, and the main base 30 The seat 30 is locked with the fixed plate 31, and the main seat 30 and the fixed plate 31 are embedded on the bottom frame 32. The textiles detected at the winding structure 1 are more likely to cause inclination, and the fixed plate 31 acts on the main seat. 30 to strengthen and maintain the gravity balance of the tester, the winding structure 1 includes a disc structure 10, a ring structure 11, and a rod structure 12, and the rin...

Embodiment 2

[0028] Example 2 see Figure 6-7 , the present invention provides a technical scheme of a fabric elastic recovery tester based on double testing of bracket reinforcement data: the measuring auxiliary device 100 in its structure includes an auxiliary device installation shaft 1000, an installation square plate 1001, a device barrel 1002, and a wire pulling structure 1003 , the auxiliary device installation shaft 1000 is axially connected to the installation square plate 1001, the installation square plate 1001 is track-connected to the device barrel 1002, the device barrel 1002 is embedded with the wire pulling structure 1003, and the rod structure 12 is connected to the wire pulling structure The structure 1003 realizes the double data test on the weaving strip, and the test result is more accurate. The wire pulling structure 1003 includes a wire pulling frame 400, a pressing plate 401, a buffer strip 402, and a concave-convex wheel 403. The wire pulling frame 400 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com