Method for analyzing development degree of inner seam of quartz grain

A technology of development degree and quartz, which is applied in the field of analyzing the development degree of inner fractures of quartz grains, and can solve the problems that it is difficult to know the development degree of inner fractures of quartz grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

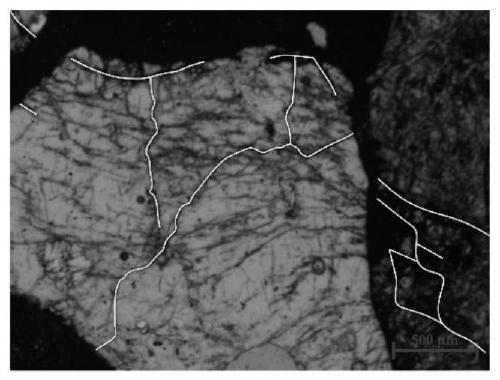

[0030] Please refer to Figure 1a , the embodiment of the present invention provides a kind of method based on man-made rock core technology to evaluate the development degree of the inner fracture of quartz grain, comprising the following steps:

[0031] (1) Take (less than 10 mesh) sand and 20% volume white cement according to the volume percentage and mix and stir evenly to obtain a mineral powder mixture, add distilled water equal to the volume of white cement, and mix and stir to obtain artificial rock core raw materials. The volume percentage of sand and white cement is 5:1.

[0032] (2) A circle of polytetrafluoroethylene film is placed close to the inner wall of the core tube, and then the uniformly stirred raw materials are placed in it and pre-compacted.

[0033] (3) Heat and pressurize (100° C., 20 MPa) to prepare artificial sandstone cores.

[0034] (4) The artificial rock core made into ordinary thin slices, observed under a microscope, and counted 4mm 2 The num...

Embodiment 2

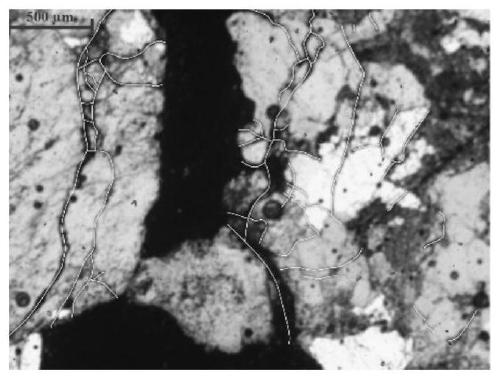

[0036] Please refer to Figure 2a , the embodiment of the present invention provides a kind of method based on man-made rock core technology to evaluate the development degree of the inner fracture of quartz grain, comprising the following steps:

[0037] (1) Take (10-16 mesh) sand and 20% volume white cement according to the volume percentage, mix and stir evenly to obtain a mineral powder mixture, add distilled water equal to the volume of white cement, and mix and stir to obtain artificial rock core raw materials. The volume percentage of sand and white cement is 5:1.

[0038] (2) A circle of polytetrafluoroethylene film is placed close to the inner wall of the core tube, and then the uniformly stirred raw materials are placed in it and pre-compacted.

[0039] (3) Heat and pressurize (100° C., 20 MPa) to prepare artificial sandstone cores.

[0040] (4) The artificial rock core made into ordinary thin slices, observed under a microscope, and counted 4mm 2 The number of cr...

Embodiment 3

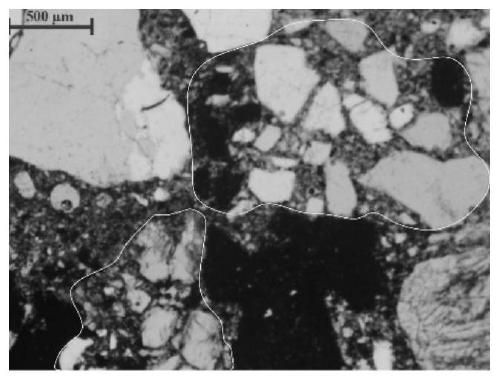

[0042] Please refer to Figure 3a , the embodiment of the present invention provides a kind of method based on man-made rock core technology to evaluate the development degree of the inner fracture of quartz grain, comprising the following steps:

[0043] (1) Take sand (greater than 32 mesh) and 20% volume of white cement according to the volume percentage, mix and stir evenly to obtain a mineral powder mixture, add distilled water equal to the volume of white cement, and mix and stir to obtain artificial rock core raw materials. The volume percentage of sand and white cement is 5:1.

[0044] (2) A circle of polytetrafluoroethylene film is placed close to the inner wall of the core tube, and then the uniformly stirred raw materials are placed in it and pre-compacted.

[0045] (3) Heat and pressurize (100° C., 20 MPa) to prepare artificial sandstone cores.

[0046] (4) The artificial rock core made into ordinary thin slices, observed under a microscope, and counted 4mm 2 The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com