Water treatment agent used for oilfield reinjection water and preparation method thereof

A technology for reinjecting water and water treatment agents in oilfields, which is applied in biological water/sewage treatment, water/sludge/sewage treatment, sterilization/microdynamic water/sewage treatment, etc., and can solve unstable water quality and easy blockage of pipelines , complex ionic components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The present invention also provides a method for preparing the above-mentioned water treatment agent for oilfield reinjection water, comprising the following steps:

[0035] C9 petroleum resin, polyacrylamide, N,N'-sodium dilauroyl ethylenediamine diacetate, zeolite, bentonite, fumed silica, microbial agent, inorganic salt, corrosion inhibitor, scale inhibitor, at 40 Stir at ~50°C for 4-6 hours to obtain the water treatment agent for oilfield reinjection water.

[0036] Among them, C9 petroleum resin, polyacrylamide, N,N'-sodium dilauroyl ethylenediamine diacetate, zeolite, bentonite, fumed silica, microbial agent, inorganic salt, corrosion inhibitor, and scale inhibitor are the same as above mentioned, and will not be repeated here.

[0037] In the above technical solution, the preparation method is simple, and the prepared water treatment agent for oilfield reinjection water has good scale inhibition ability and bactericidal ability at the same time, improves water p...

Embodiment 1

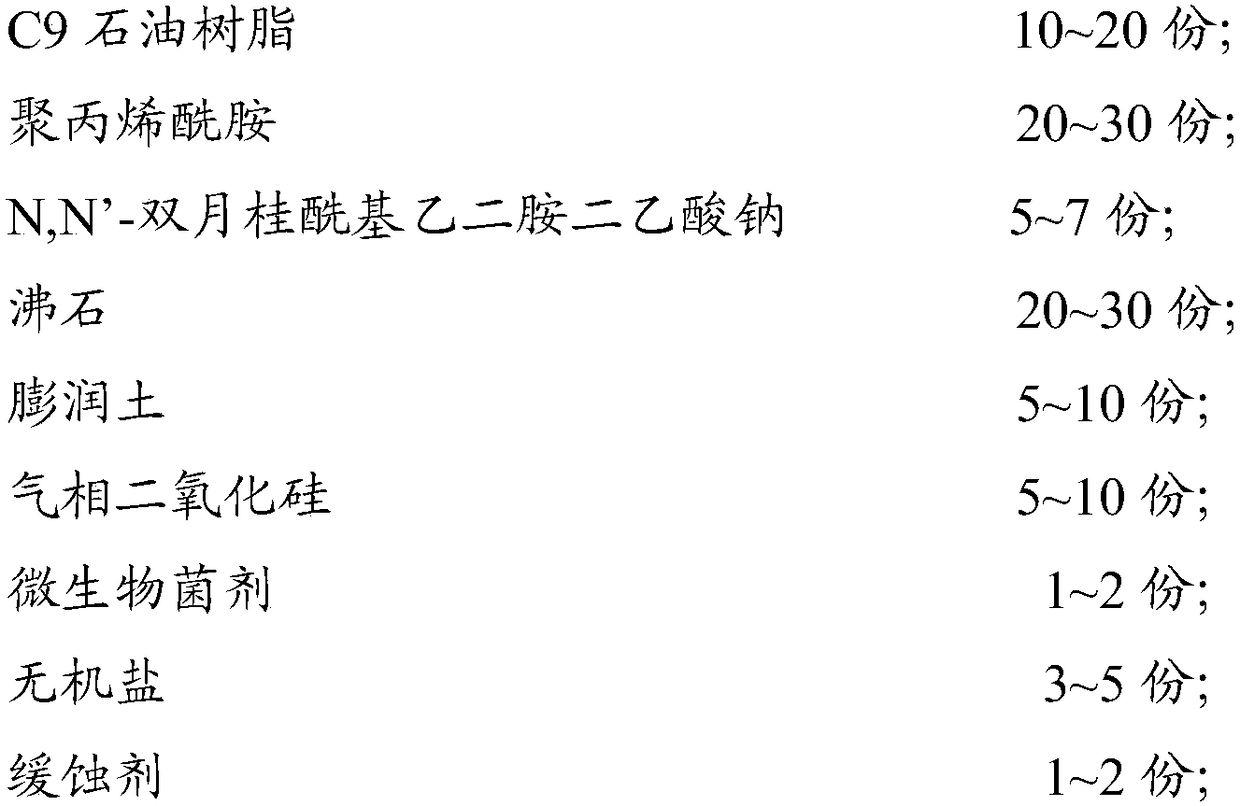

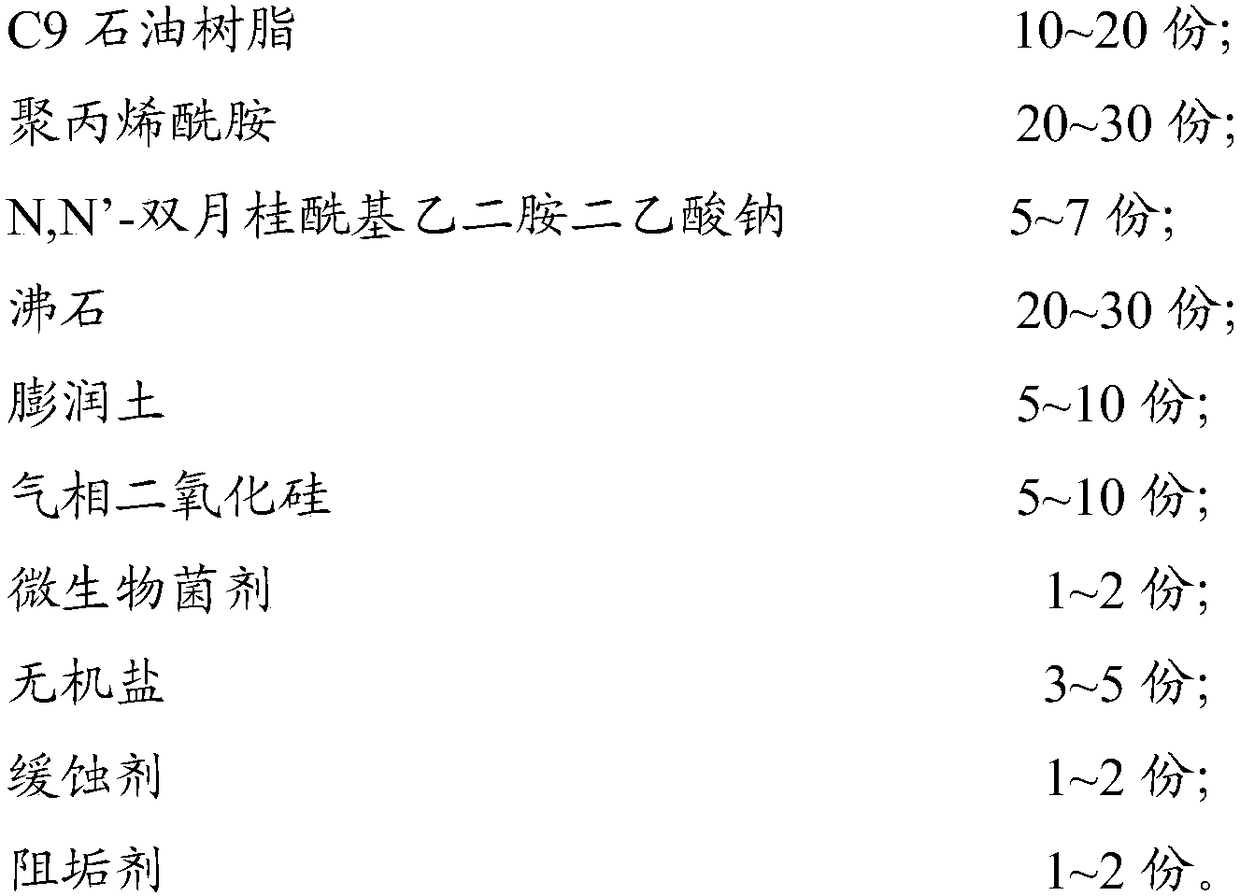

[0040] The water treatment agent for oilfield reinjection water comprises the following raw materials in parts by weight:

[0041] 16 parts of C9 oil resin, 24 parts of polyacrylamide, 6.5 parts of N,N'-dilauroyl ethylenediamine diacetate sodium, 27 parts of zeolite, 8.5 parts of bentonite, 8 parts of fumed silica, 1.4 parts of microbial agent, 3 parts of sodium chloride, 1.6 parts of corrosion inhibitor, 1.7 parts of scale inhibitor;

[0042] Microbial agents include Thiobacillus denitrificans, Chlamydia planktonicus, Phanerochaete chrysosporium with a mass ratio of 1.8:0.45:0.65;

[0043] The corrosion inhibitor includes sodium silicate, sodium citrate, calcium chloride, chitosan and houttuyniatin with a mass ratio of 0.65:1:2:0.9:0.55;

[0044] The scale inhibitor includes horse-propylene copolymer, dodecylamine polyoxyethylene ether, sodium polyacrylate, hydroxypropyl acrylate and ethylene glycol with a mass ratio of 0.6:1.3:1.4:0.6:1.1.

[0045] The preparation method o...

Embodiment 2

[0048] The water treatment agent for oilfield reinjection water comprises the following raw materials in parts by weight:

[0049] 20 parts of C9 oil resin, 20 parts of polyacrylamide, 5.5 parts of N,N'-dilauroyl ethylenediamine diacetate sodium, 30 parts of zeolite, 6.5 parts of bentonite, 10 parts of fumed silica, 1.6 parts of microbial agent, 3.5 parts of aluminum sulfate, 2 parts of corrosion inhibitor, 1 part of scale inhibitor;

[0050] Microbial agents include Thiobacillus denitrificans, Chlamydia planktonicus, Phanerochaete chrysosporium with a mass ratio of 1:0.5:0.8;

[0051]Corrosion inhibitors include sodium silicate, sodium citrate, calcium chloride, chitosan and houttuyn with a mass ratio of 0.7:2:1:1.1:0.45;

[0052] The antiscalant includes horse-propylene copolymer, dodecylamine polyoxyethylene ether, sodium polyacrylate, hydroxypropyl acrylate and ethylene glycol at a mass ratio of 0.7:1.7:1.2:0.4:1.3.

[0053] The preparation method of water treatment agen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com