Filling method of redundant metal

A filling method and technology of redundant graphics, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as large differences in the density of redundant graphics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

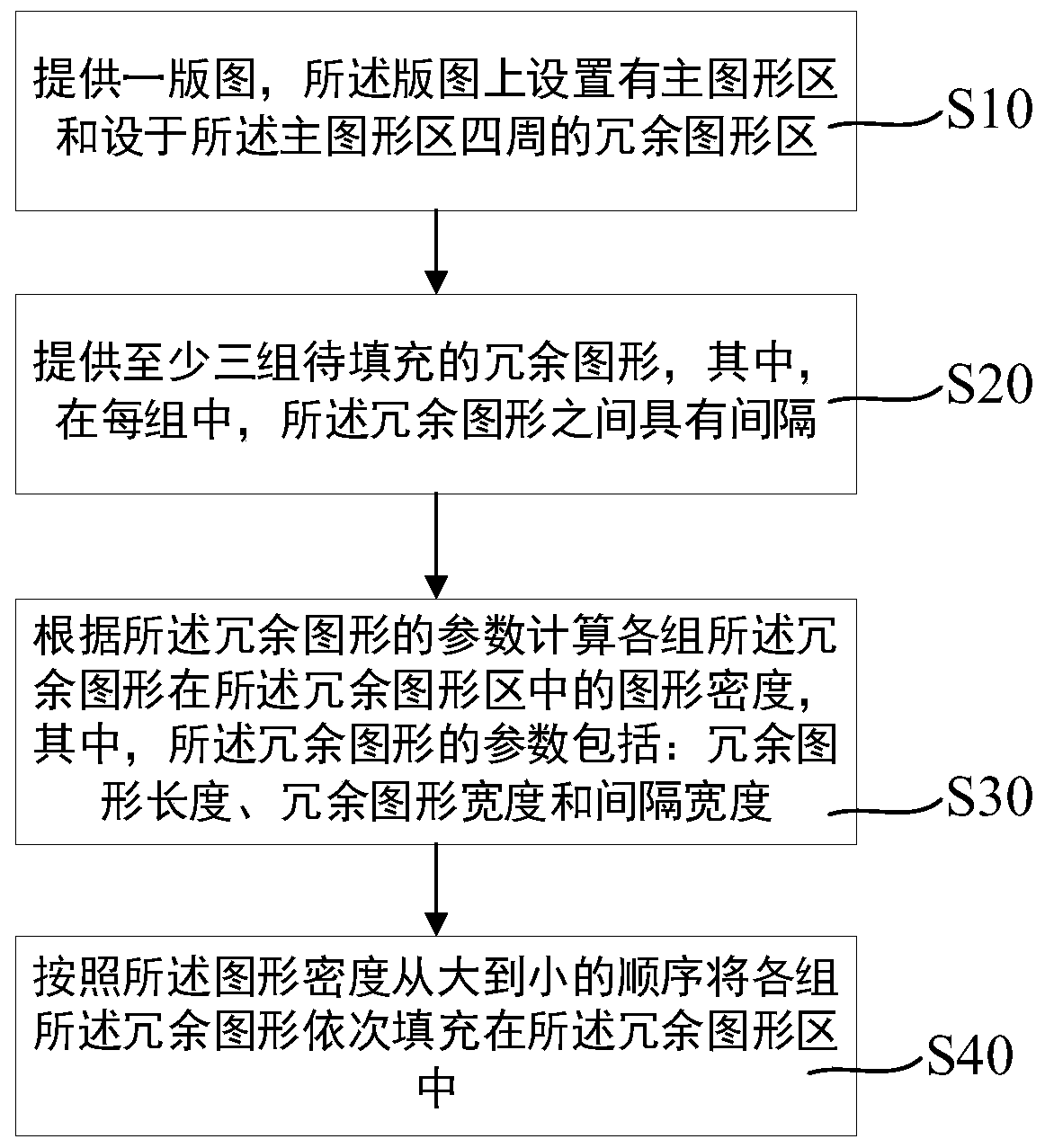

[0041] The present invention provides a filling method of redundant graphics, refer to figure 1 , figure 1 It is a flowchart of a method for filling redundant graphics in Embodiment 1 of the present invention. In this embodiment, the method for filling redundant graphics includes:

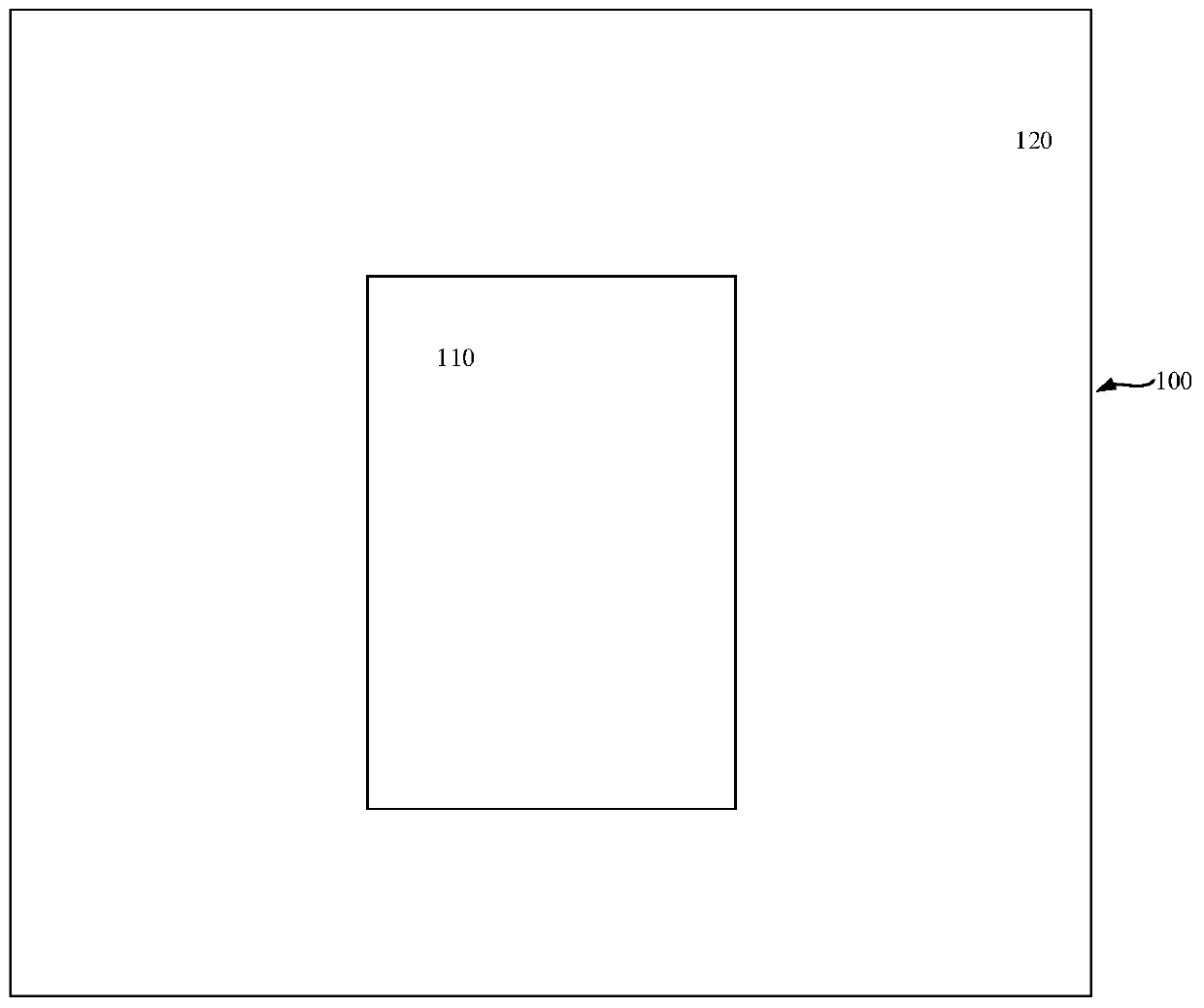

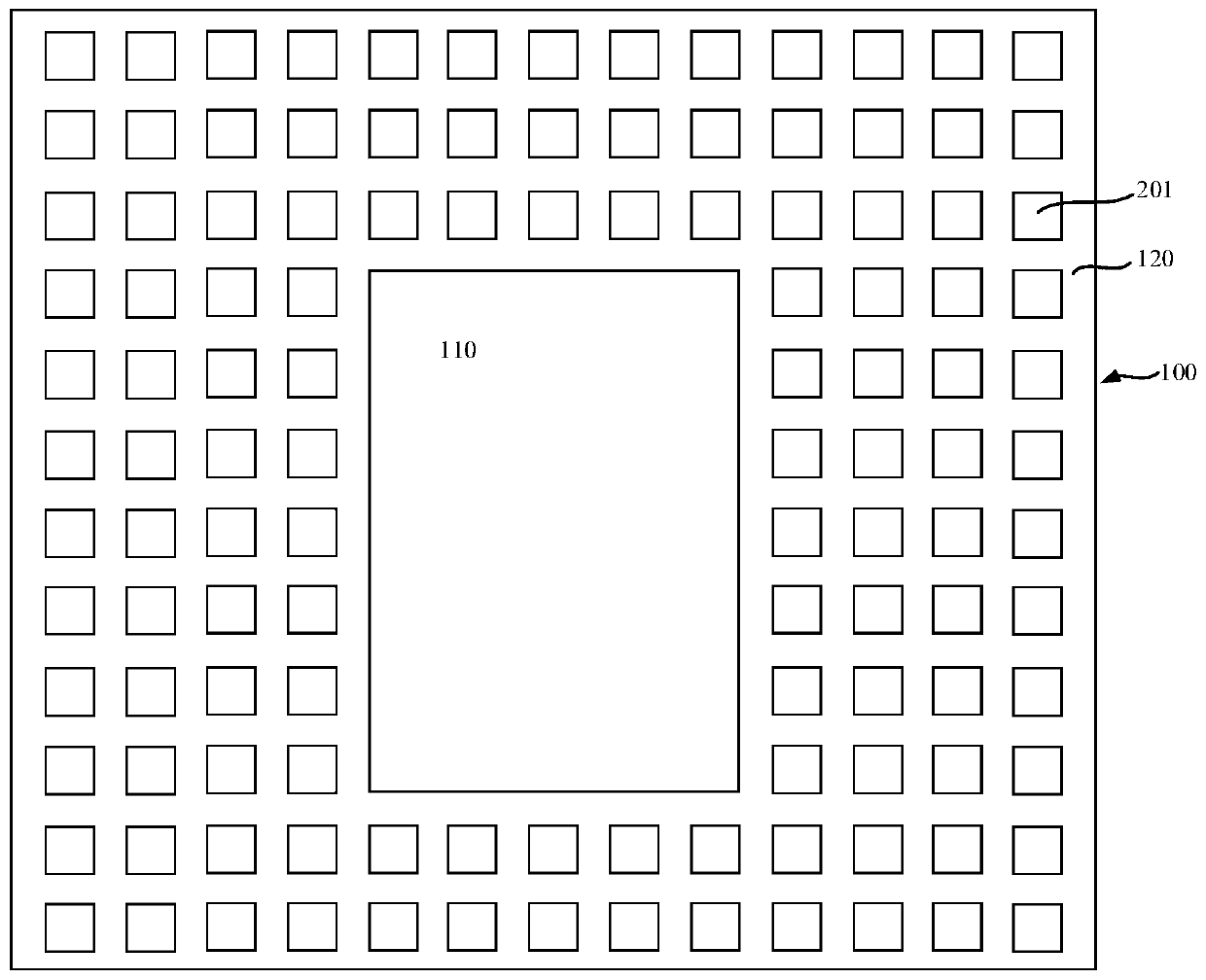

[0042] S10: providing a layout, the layout is provided with a main graphics area and redundant graphics areas around the main graphics area;

[0043] S20: providing at least three groups of redundant graphics to be filled, wherein, in each group, there is an interval between the redundant graphics;

[0044] S30: Calculate the pattern density of each group of redundant patterns in the redundant pattern area according to the parameters of the redundant patterns, wherein the parameters of the redundant patterns include: redundant pattern length, redundant pattern width and interval width;

[0045] S40: Fill each group of redundant graphics in the redundant graphics area sequentially in descending o...

Embodiment 2

[0055] In this example, refer to Figure 6 , Figure 6 It is a flowchart of a method for filling redundant graphics according to Embodiment 2 of the present invention, and the method for filling redundant graphics includes:

[0056] S10: providing a layout, the layout is provided with a main graphics area and redundant graphics areas around the main graphics area;

[0057] S20: providing at least three groups of redundant graphics to be filled, wherein, in each group, there is an interval between the redundant graphics;

[0058] S30: Calculate the pattern density of each group of redundant patterns in the redundant pattern area according to the parameters of the redundant patterns, wherein the parameters of the redundant patterns include: redundant pattern length, redundant pattern width and interval width;

[0059] S40: Divide the redundant graphic area into a first graphic area, a second graphic area to an n-th graphic area in the order from the redundant graphic area to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Interval width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com