Triple Graphical Approach

A re-patterning and patterning technology, applied in the manufacturing of electrical components, circuits, semiconductor/solid-state devices, etc., can solve problems such as increasing pattern density, pattern size process limitations, and complex manufacturing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

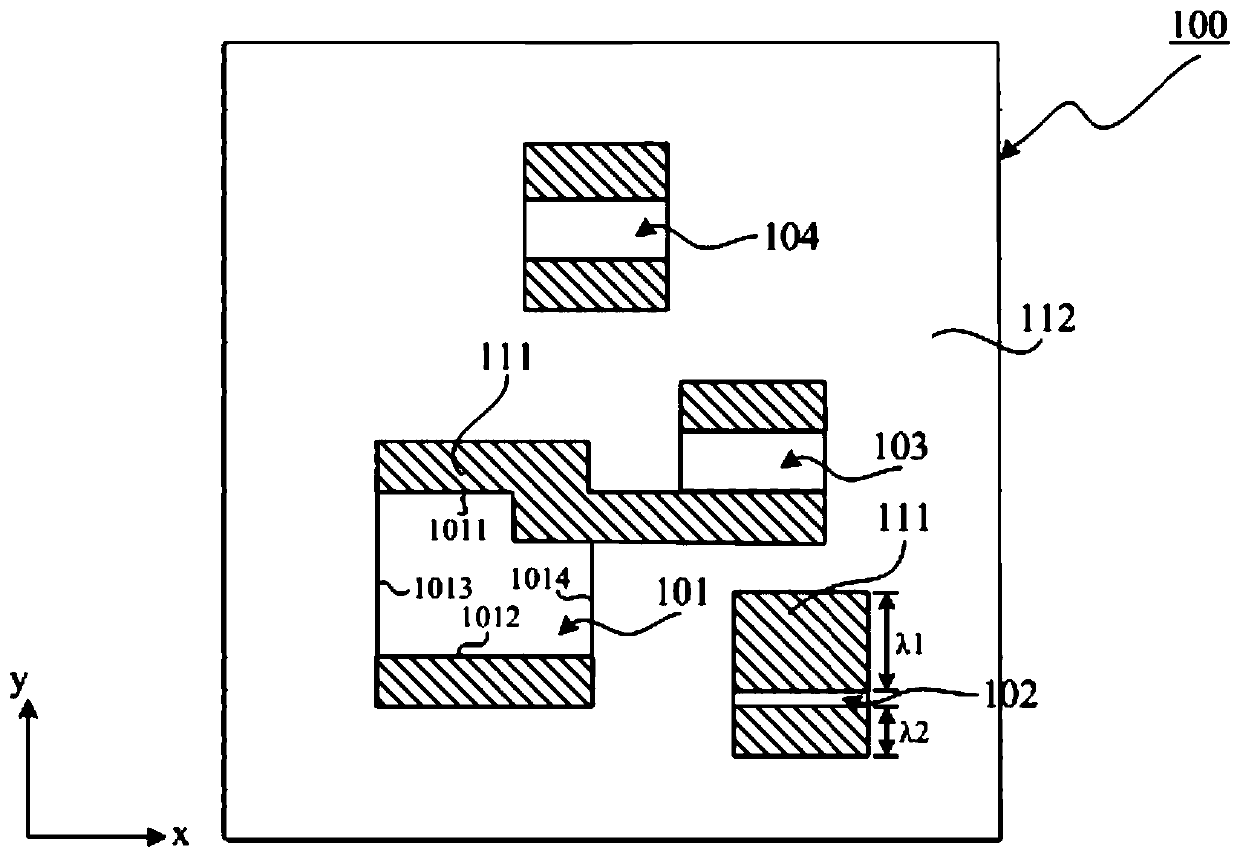

[0033] refer to figure 1 , is a schematic diagram of the structure of an intermediate step in a dual patterning method.

[0034] A substrate is provided, and a mask layer 100 is formed on the surface of the substrate.

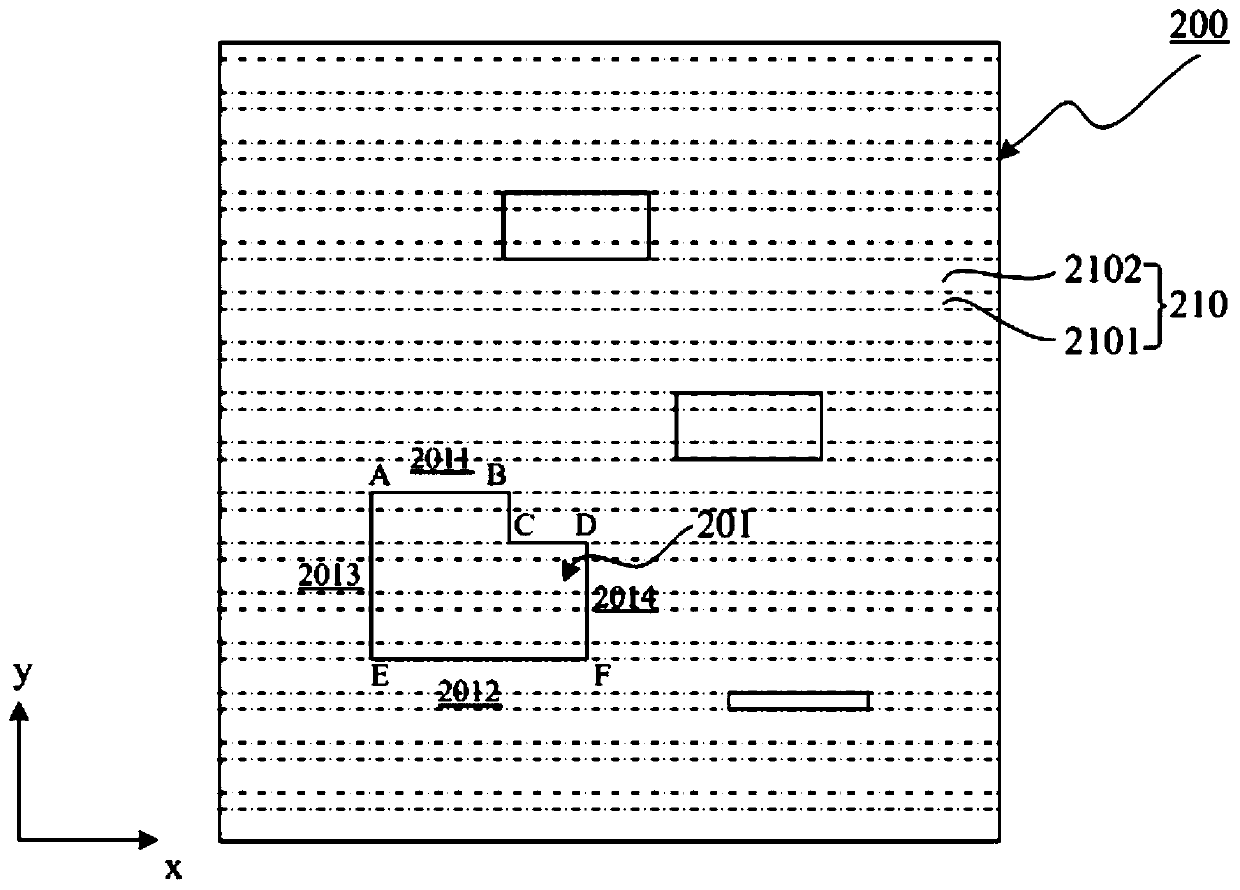

[0035] Target graphics are provided, including target graphics 101 , 102 , 103 and 104 , and the target graphics are used to define areas to be patterned on the substrate. Here, the method of double graphics is described by taking the target graphics 101 as an example. First use the first reticle to pattern the mask layer 100, remove the first part of the mask layer 111, to define the first boundary 1011 and the second boundary 1012 of the target pattern 101 along the x direction, and then use The second mask plate performs patterning on the mask layer 100 to remove the second part of the mask layer 112 to define the third boundary 1013 and the fourth boundary 1014 of the target pattern 101 along the y direction.

[0036] The size of the pattern formed by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com