Display panel and preparation method thereof

A technology for display panels and array substrates, which is applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve problems such as low efficiency of miniature light-emitting diodes, and achieve the effect of improving the preparation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

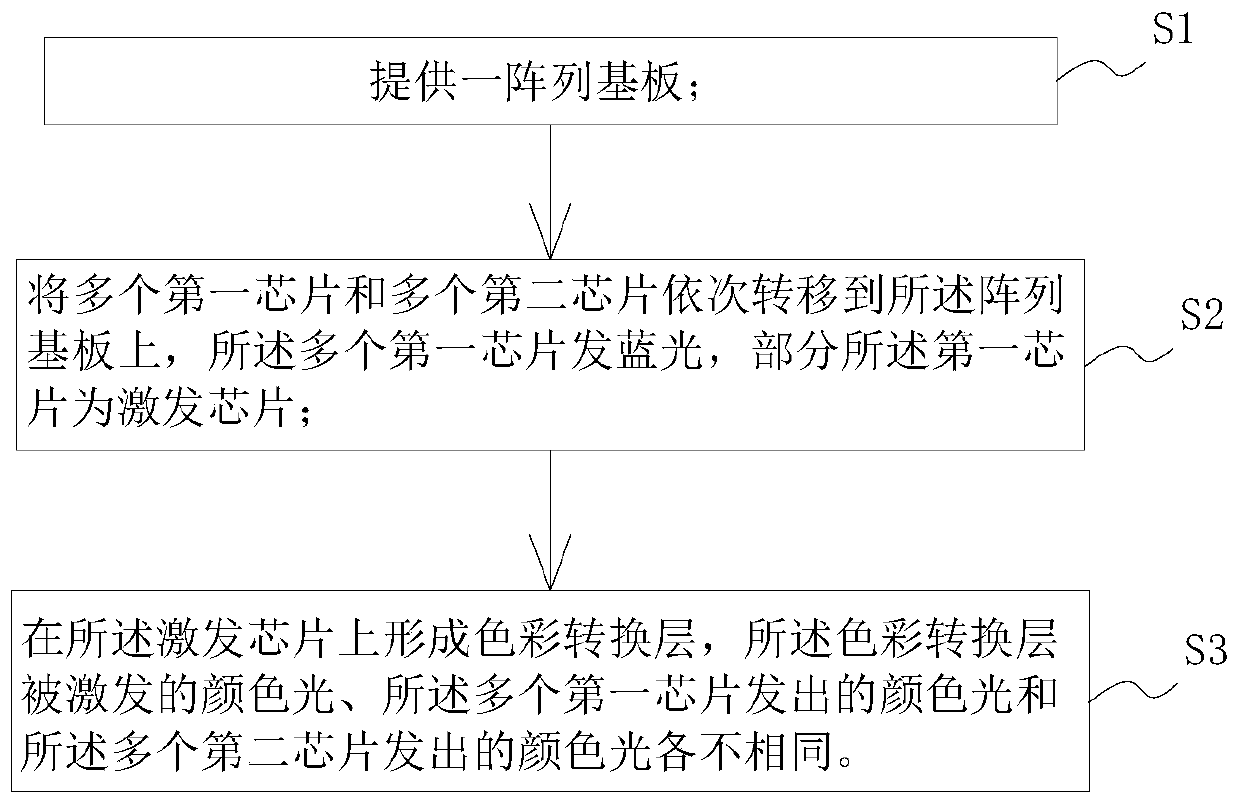

[0078] The method for manufacturing a display panel according to the first embodiment of the present application includes the following steps:

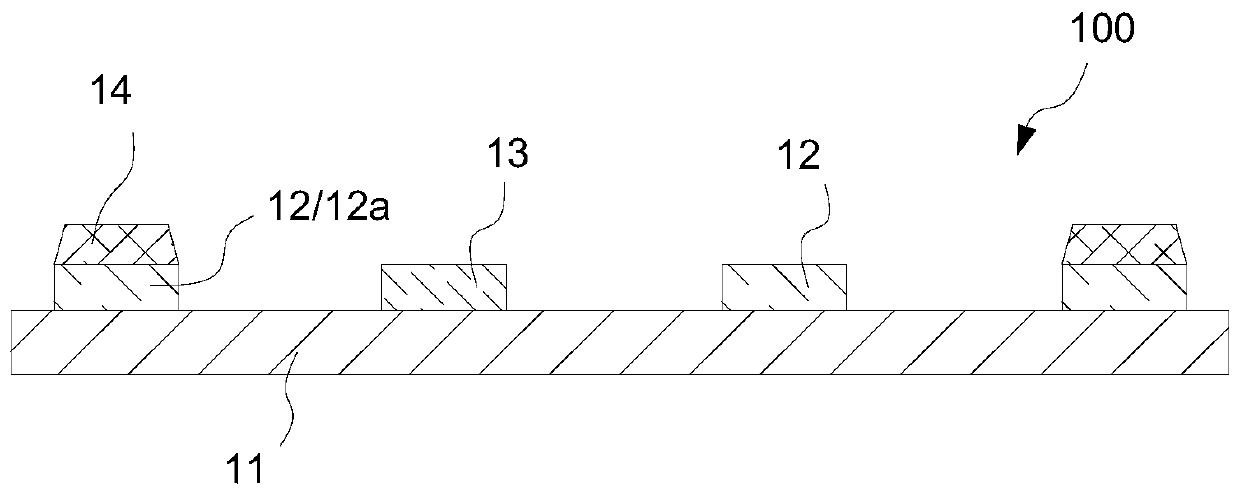

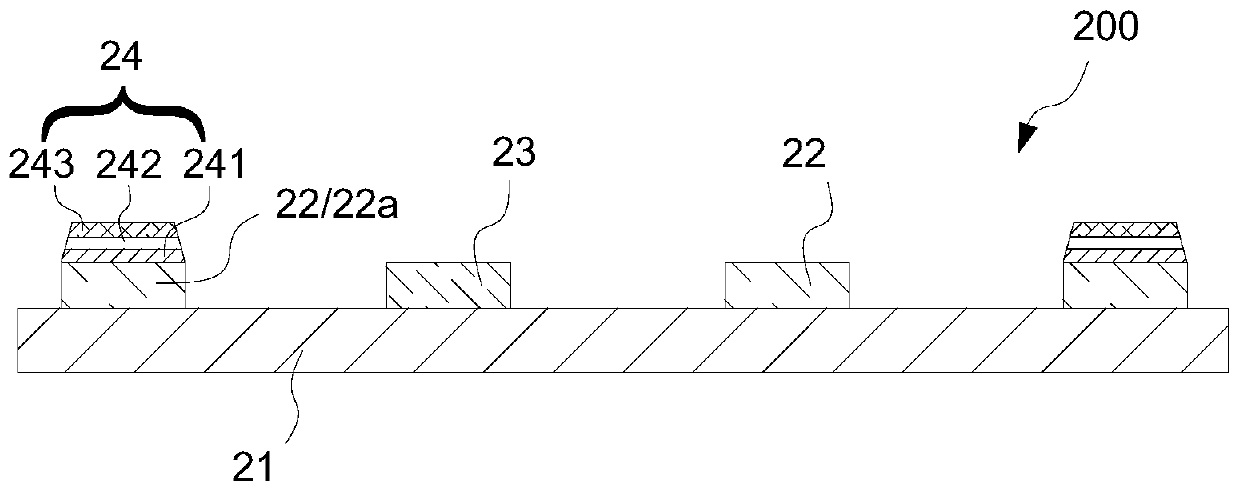

[0079] Step S1: providing an array substrate 11;

[0080] Step S2: sequentially transferring multiple first chips 12 and multiple second chips 13 onto the array substrate 11, the multiple first chips 12 emit blue light, and some of the first chips 12 are excitation chips 12a;

[0081] Step S3: forming a color conversion layer 14 on the excitation chip 12a, the color light excited by the color conversion layer 14, the color light emitted by the plurality of first chips 12 and the color light emitted by the plurality of second chips 13 The color light varies.

[0082] The manufacturing method of the display panel in the first embodiment only needs to transfer the first chip 12 and the second chip 13 twice, and then form the color conversion layer 14 on the excitation chip 12a, so that the excitation chip 12a emits light and excites the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com