Manually-operated motor base adjuster

A motor base, manual operation technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of low efficiency, large consumption of manpower and material resources, cumbersome operation, etc., to achieve high efficiency, less consumption of manpower and material resources, and improve operation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with accompanying drawing:

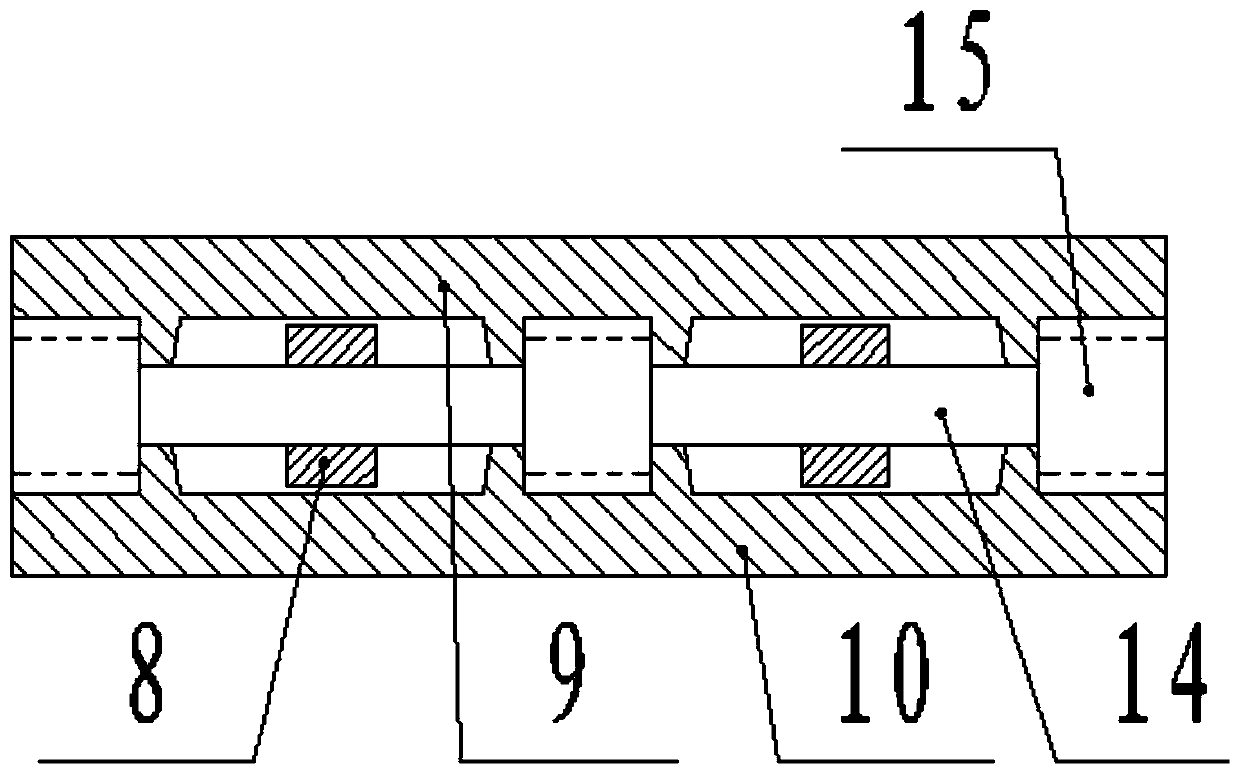

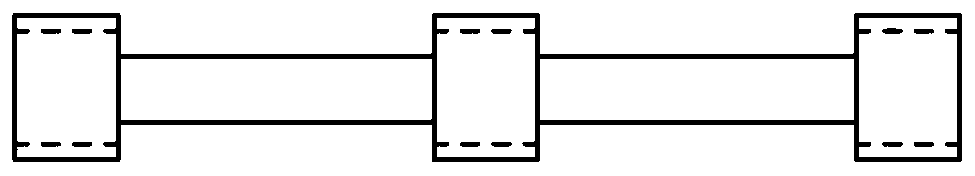

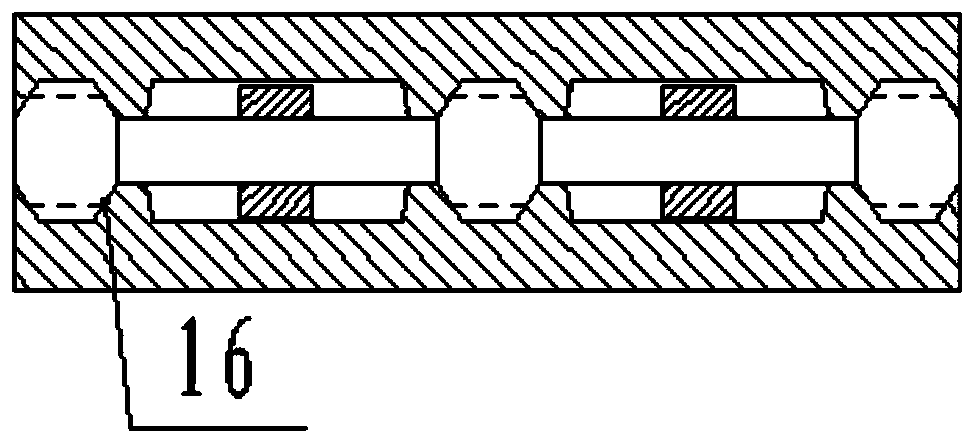

[0036] Such as figure 1 As shown, the present embodiment includes an upper plate 9, a lower plate 10, a roller 11 and a driving mechanism, wherein the upper plate 9 and the lower plate 10 are arranged in parallel up and down, and the roller 11 is clamped between the upper plate 9 and the lower plate 10, A gear section 15 and a cylinder section 14 are provided on the roller shaft 11 , and a rack 12 meshing with the gear section 15 is provided on the lower side of the upper plate 9 and the upper side of the lower plate 10 . The underside of the upper plate 9 and the upper side of the lower plate 10 both abut against the cylindrical section 14 .

[0037] Roller 11 has adopted the structure form that gear section 15 and cylindrical section 14 are combined, and the setting of gear section 15 can guarantee that the position of roller 11 between upper plate 9 and lower plate 10 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com