Stirring machine for food processing

A technology for food processing and mixers, which is applied to mixers with rotating stirring devices, mixers, dissolving, etc. It can solve the problems of slow food mixing speed, single mixing method, and low equipment working efficiency, so as to improve practicability and improve Circulation flow speed, effect of improving stirring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

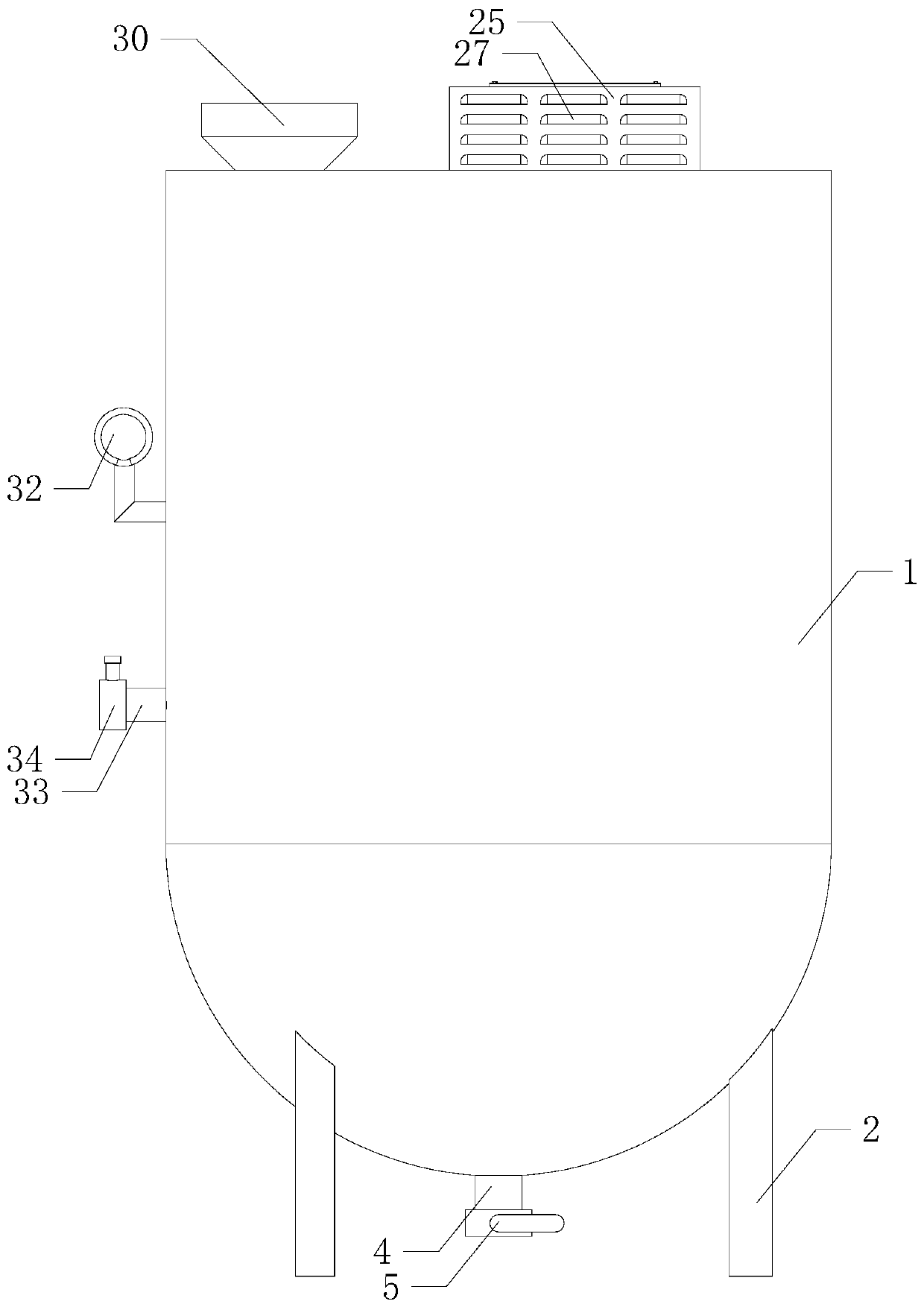

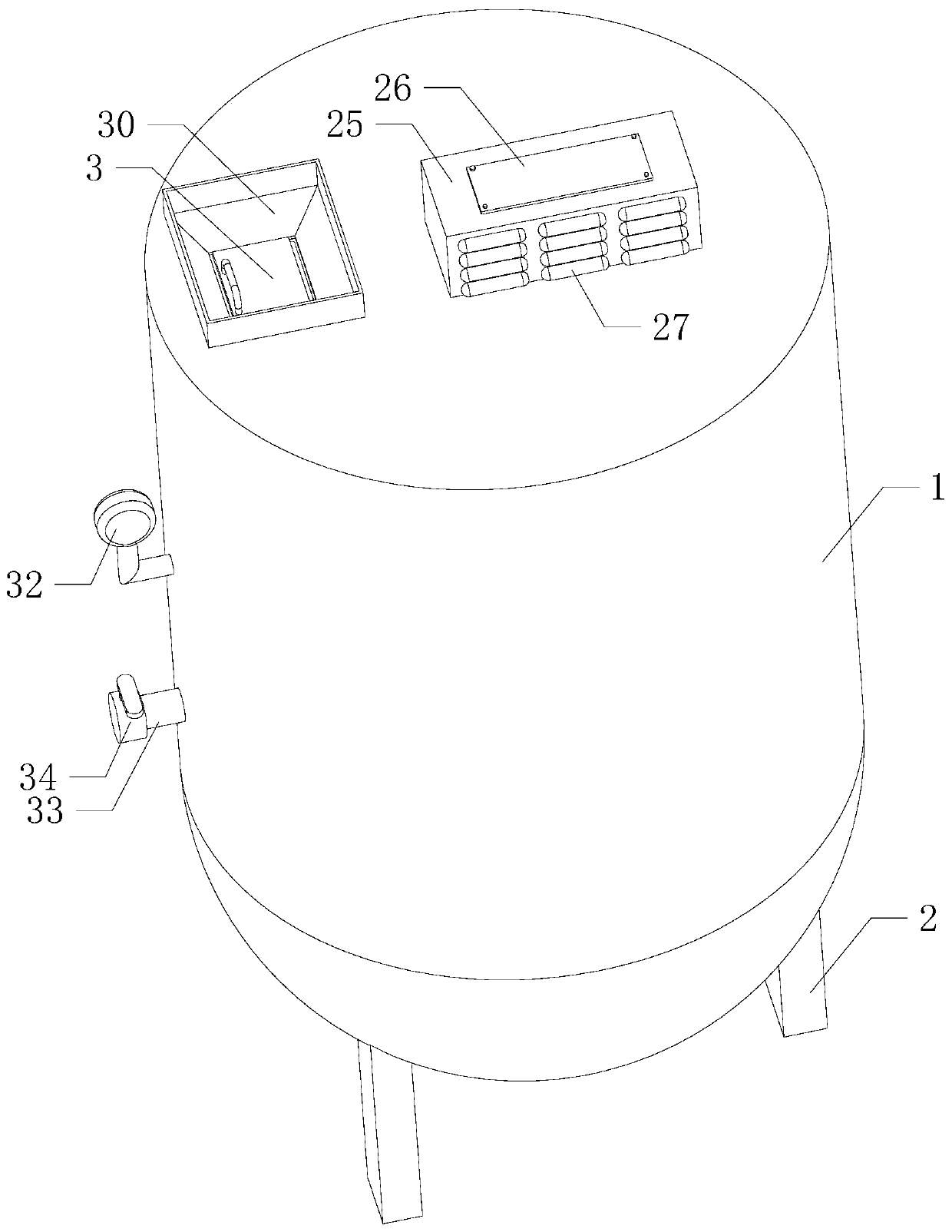

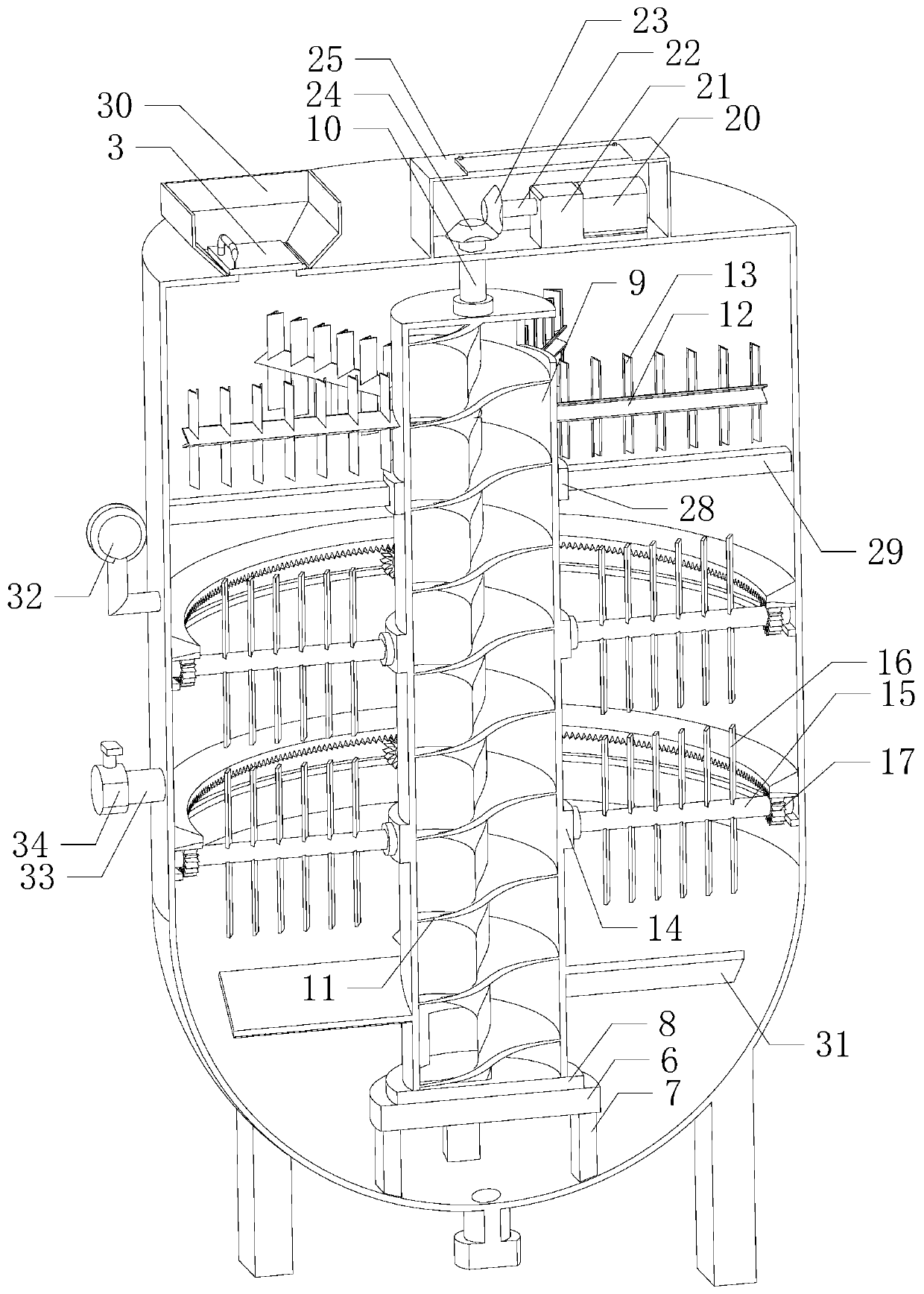

[0019] Such as Figure 1 to Figure 4As shown, a mixer for food processing of the present invention, when it is working, turns on the power device, the power device drives the rotating barrel 9 to rotate through the power shaft 10, and the rotating barrel 9 drives the screw feeding plate 11 and the rotating disk 8 on the support seat 6 At the same time, the rotating barrel 9 drives four sets of crushing main knives 12 and multiple sets of crushing auxiliary knives 13 to rotate, and the rotating barrel 9 drives multiple sets of stirring shafts 15 and multiple sets of stirring blades 16 through two sets of mounting sleeves 14. Rotate, so that multiple sets of stirring shafts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com