Gas-lifting multi-stage loop reactor for strain cultivation

A loop reactor, airlift technology, which is applied in chemical methods, chemical instruments and methods, chemical/physical processes, etc. to make liquids react with gaseous media. The distribution is not ideal and other problems, to achieve the effect of increasing the overall gas holdup, increasing the circulating liquid velocity, and improving the gas-liquid distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

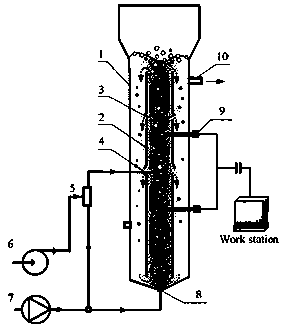

[0008] Such as figure 1 As shown, an air-lift multi-stage loop reactor for strain planting includes a guide tube 1 and a guide tube 2, the inside of the guide tube 1 is provided with a guide tube 2, and the upper part of the guide tube 2 is provided with a distribution 3, the lower part is provided with a nozzle 4, the nozzle is connected with the gas-liquid mixing tank 5, and the gas-liquid mixing tank 5 is provided with three branches, the second one is connected with the metering pump 6, the third one is connected with the air compressor 7, and the air compression The machine 7 is also connected with the sprayer 8, the sprayer 8 is placed at the bottom of the guide tube 1, the upper part of one side of the guide tube 1 is provided with a drain port 10, and the middle part is provided with an optical fiber probe 9.

[0009] The diameter of the guide tube 1 is 213mm.

[0010] The principle is as follows:

[0011] The guide tube 1 is divided into three sections, and the heig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com