An optimal design method for low wind speed variable speed and variable pitch wind turbine blades

A wind turbine blade, optimization design technology, applied to the direction of wind turbines, wind turbines, mechanical equipment, etc., which is consistent with the wind direction, can solve the problems of uneven and continuous blade load distribution, difficult processing and manufacturing, etc., to reduce material costs and increase The effect of large annual power generation and reduced blade chord length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0106] The wind turbine and blade parameters to be designed are shown in the following table:

[0107] Table 1 Optimal Design Parameters

[0108]

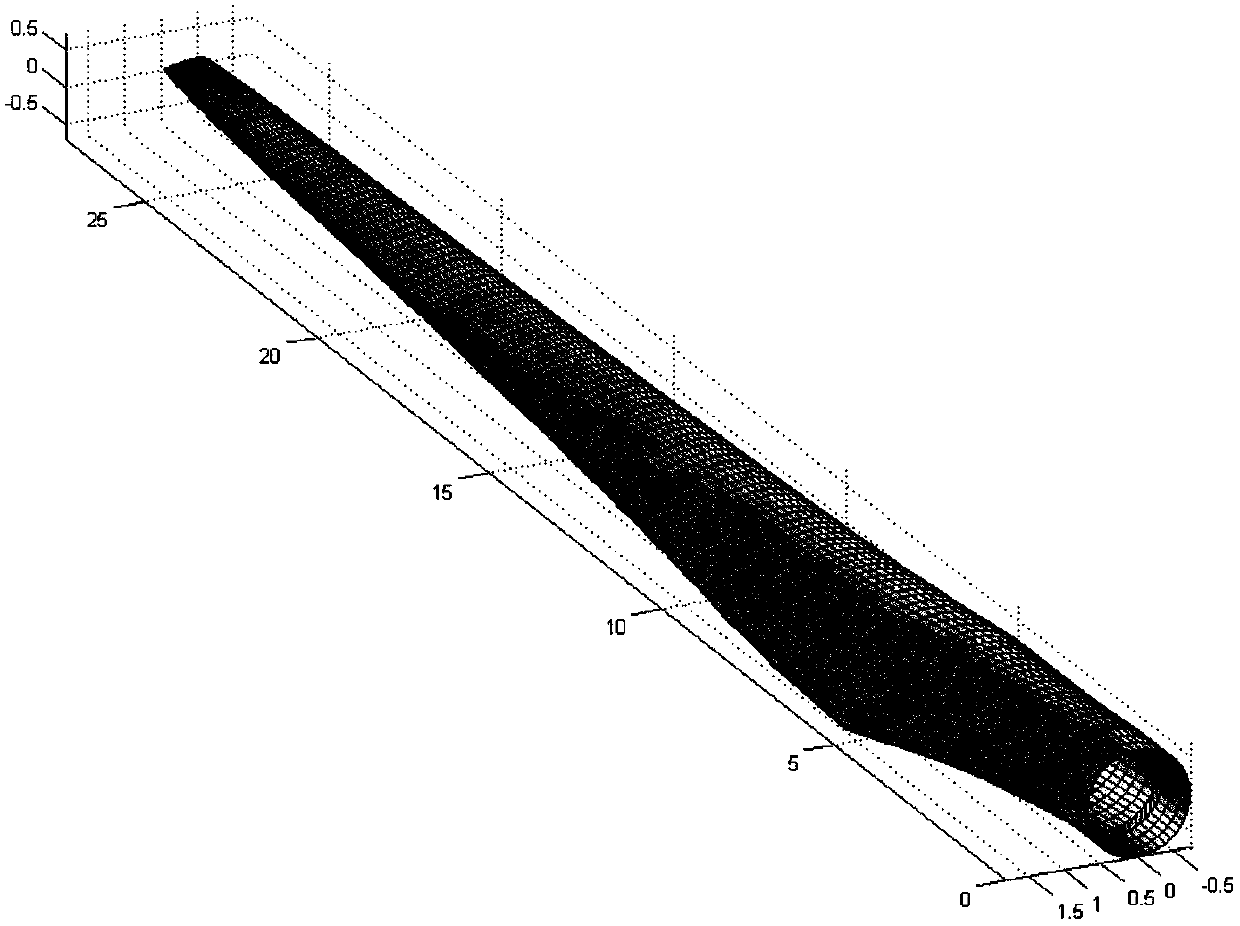

[0109] Application such as Image 6 Shown flow process, the CQU-A series airfoil family (thickness is respectively 15,18,20,25,30, 35, 40) are used for a certain 850KW blade according to the relative thickness. In order to make the calculation section truly reflect the chord length and torsion angle distribution and take into account the calculation time, a total of 30 sections are used here to calculate the aerodynamic performance of the blade.

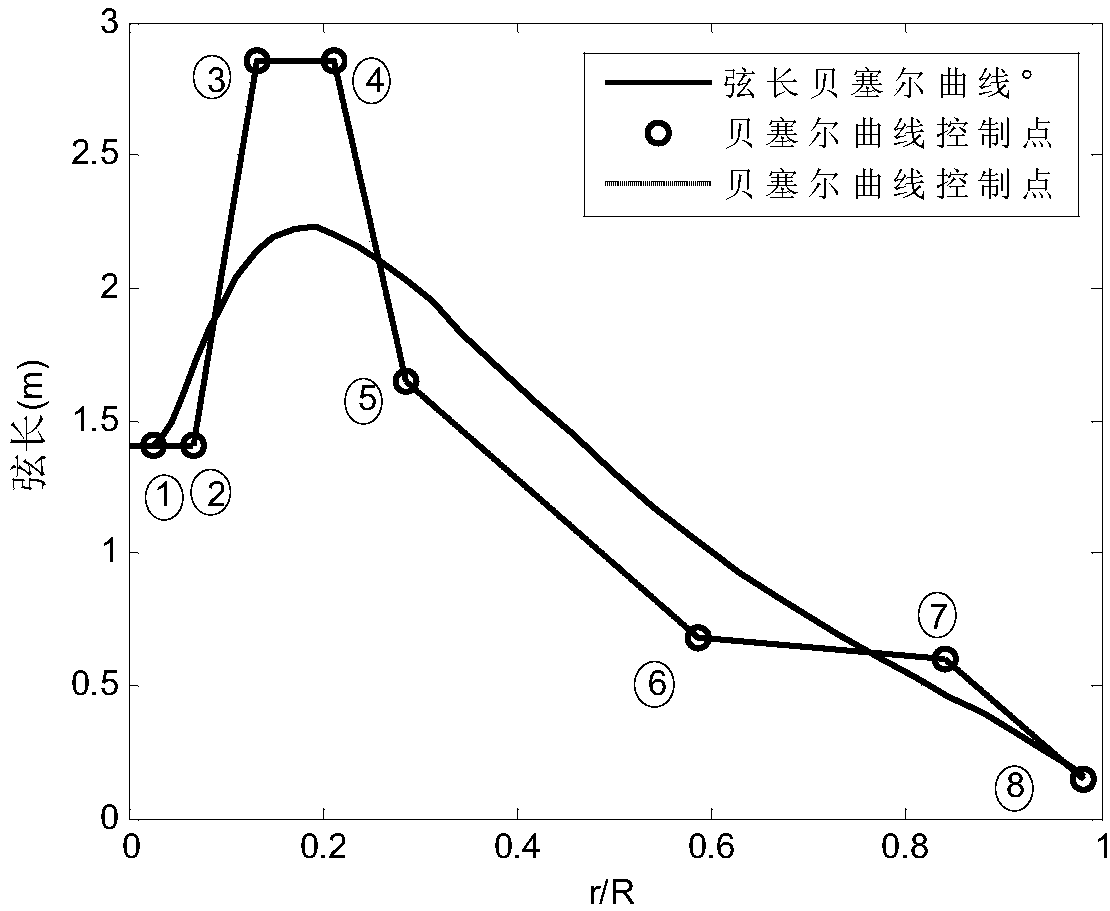

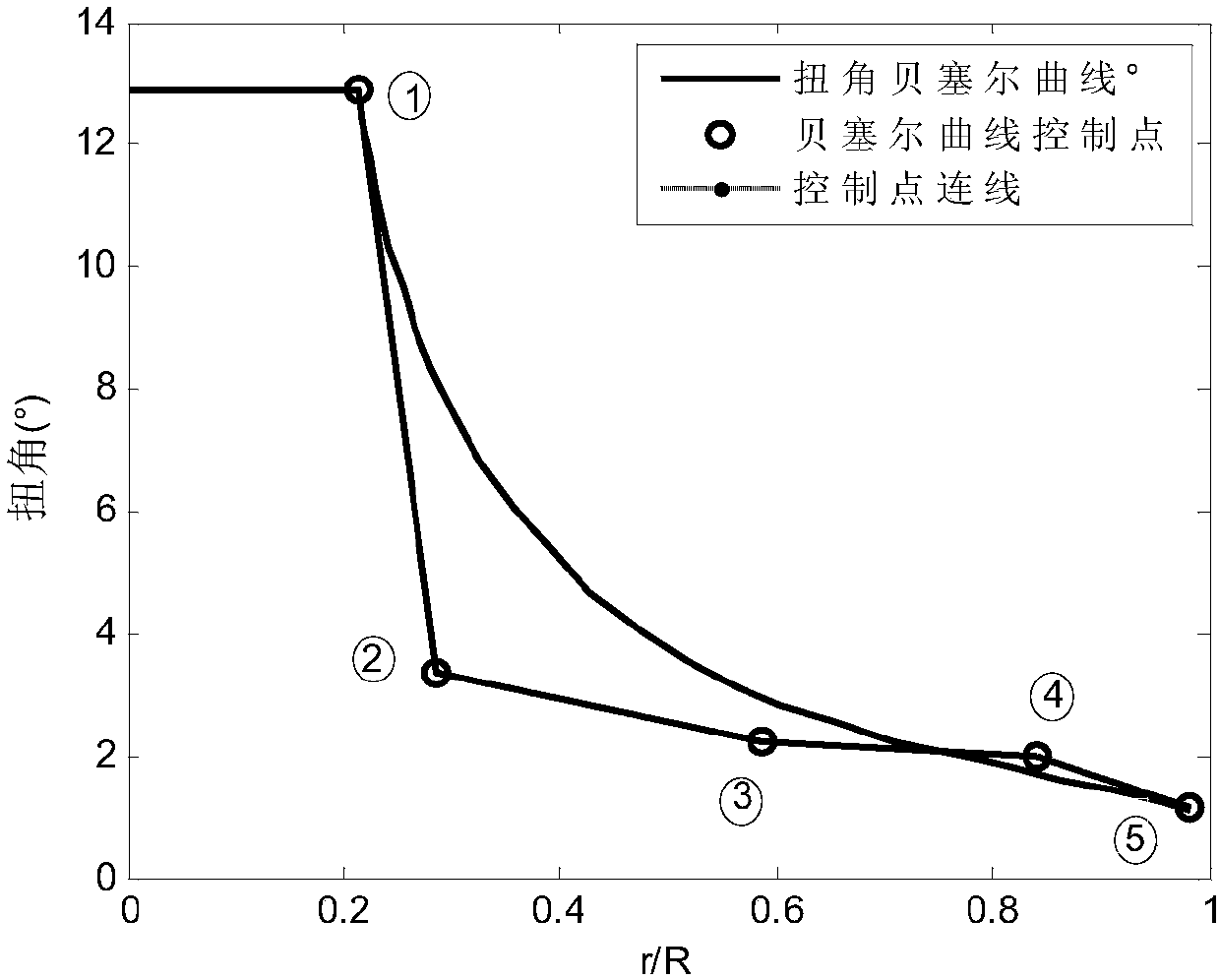

[0110] The pitch angle of the optimized blade is 0.5°, the optimal speed-torque coefficient is 0.090689, and the distribution results of chord length and torsion angle are as follows: Figure 7 and Figure 8 shown. The annual power generation of the blade before optimization is 0.9887×10 13 J, the annual power generation of the optimized blade is 1.0238×10 13 J, increased by 3.6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com