Concrete cementitious material, high-durability fair-faced concrete and preparation method thereof

A technology of fair-faced concrete and cementitious materials, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of chromatic aberration, chromatic aberration and air bubbles, to improve durability, increase compactness, reduce appearance bubble effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

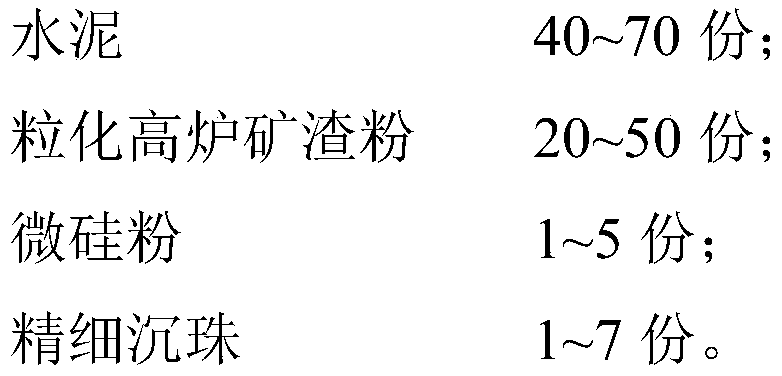

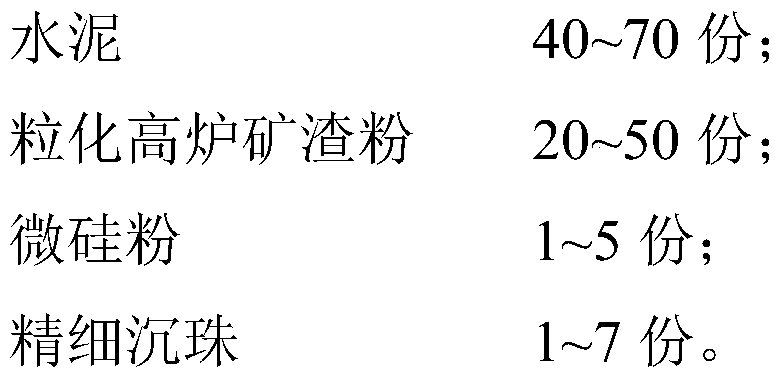

Method used

Image

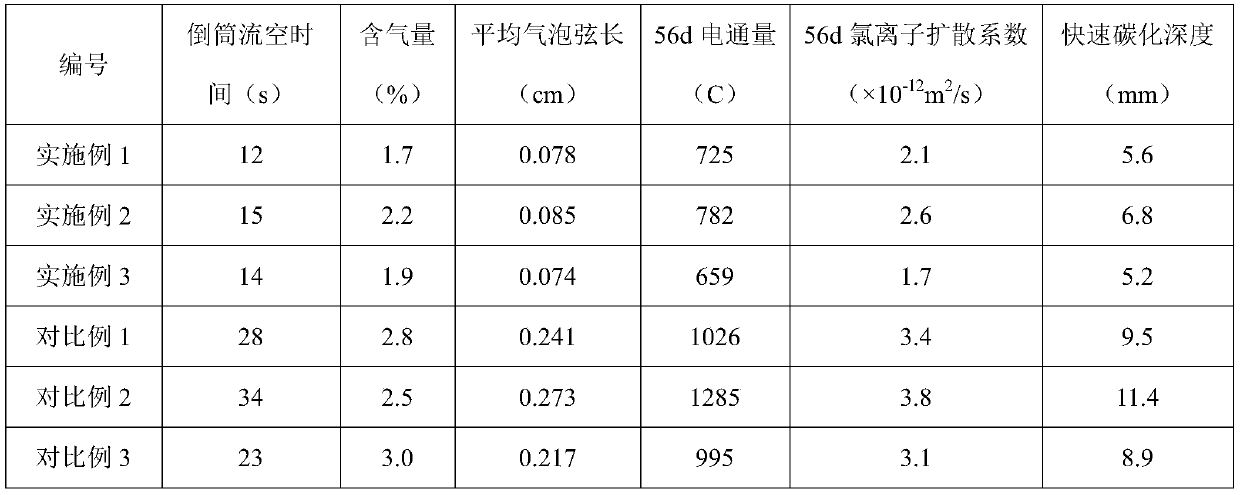

Examples

Embodiment 1

[0050] Raw materials: cement is P.Ⅱ52.5 Portland cement; granulated blast furnace slag powder is S95 granulated blast furnace slag powder; micro silica fume has a specific surface area of 18000m 2 / kg of silica fume, the activity index of 28 days is 95%; the loss on ignition of fine beads is 0.8%, the fineness is not more than 1.7μm, the water demand of standard mortar is 85%, and the 28d activity index is 114%; The water agent adopts polycarboxylate high-efficiency water-reducing agent, and the water-reducing rate is 26%; the coarse aggregate adopts continuous graded crushed stone with a particle size of 5-25mm, the content of needle flakes is 6.2%, the mud content is 0.42%, and the mud content The fine aggregate is 0.11%; the fine aggregate is natural river sand, the fineness modulus is 2.5, the mud content is 0.94%, and the mud content is 0.37%.

[0051] Mixing ratio of each raw material: cement 240kg / m 3 , mineral powder 192kg / m 3 , Silica fume 14.4kg / m 3 , fine sinki...

Embodiment 2

[0054] Raw materials: cement is P.O 42.5 ordinary Portland cement; fine aggregate is natural river sand with a fineness modulus of 2.7, a mud content of 1.52%, and a mud content of 0.68%; granulated blast furnace slag powder, microsilica powder, Fine sinking beads, water reducer, and coarse aggregate are the same as in Example 1.

[0055] Mixing ratio of each raw material: cement 264kg / m 3 , mineral powder 132kg / m 3 , Silica fume 17.6kg / m 3 , fine sinking beads 26.4kg / m 3 , gravel 1079kg / m 3 , river sand 735kg / m 3 , water 149.6kg / m 3 , water reducer 4.5kg / m 3 .

[0056] According to the preparation method of the aforementioned high-durability fair-faced concrete, the total mixing time is 160s, thereby preparing the corresponding high-durability fair-faced concrete.

Embodiment 3

[0058] Raw material: Polycarboxylate high-efficiency water reducer is used as water reducing agent, and the water reducing rate is 23%; the coarse aggregate is continuously graded crushed stone with a particle size of 5-20mm, the needle flake content is 8.5%, and the mud content is 0.73%. The mud content is 0.29%; the fine aggregate is natural river sand with a fineness modulus of 2.4, a mud content of 0.85%, and a mud content of 0.29%; example 1.

[0059] Mixing ratio of each raw material: cement 250kg / m 3 , mineral powder 200kg / m 3 , Silica fume 25kg / m 3 , fine sinking beads 25kg / m 3 , gravel 1048kg / m 3 , river sand 717kg / m 3 , water 150kg / m 3 , water reducer 6.5kg / m 3 .

[0060] According to the preparation method of the aforementioned high-durability fair-faced concrete, the total mixing time is 150s, thereby preparing the corresponding high-durability fair-faced concrete.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| power level | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com