Miniature light transmitting-receiving integrated modular structure capable of hot plug

A hot-plug, optical transceiver technology, applied in the field of communication, can solve the problems of long production cycle, high manufacturing cost, environmental pollution and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

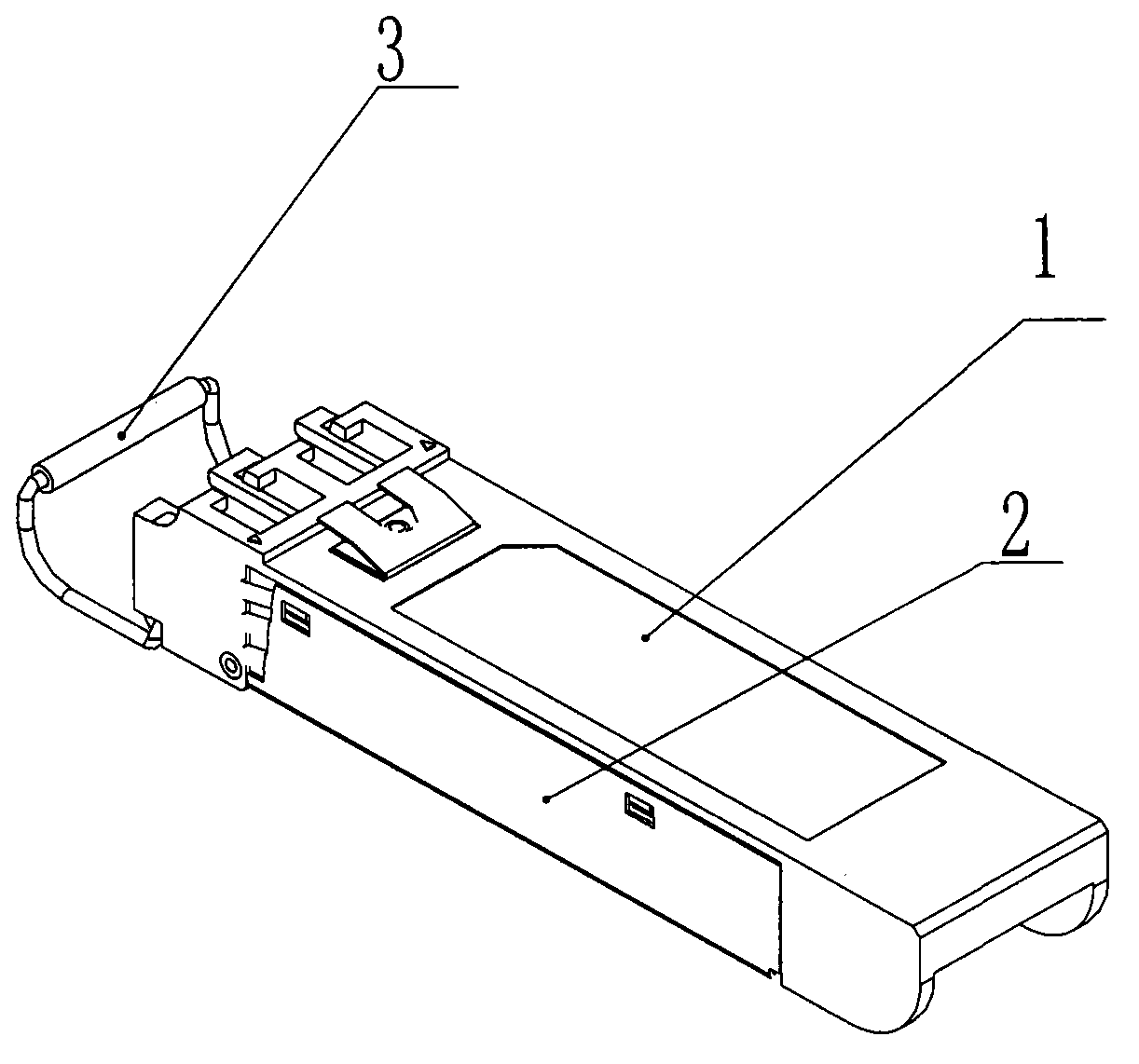

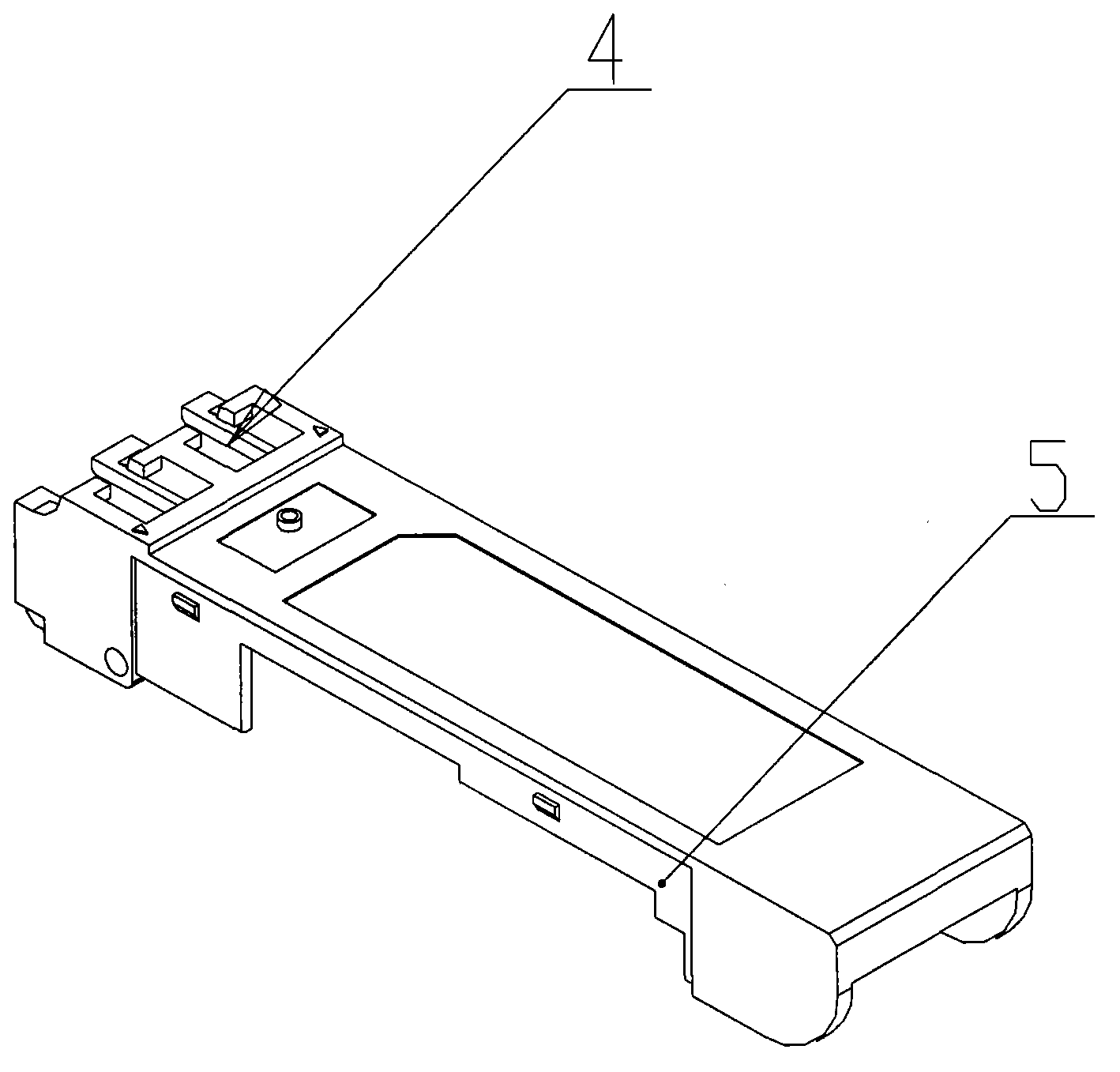

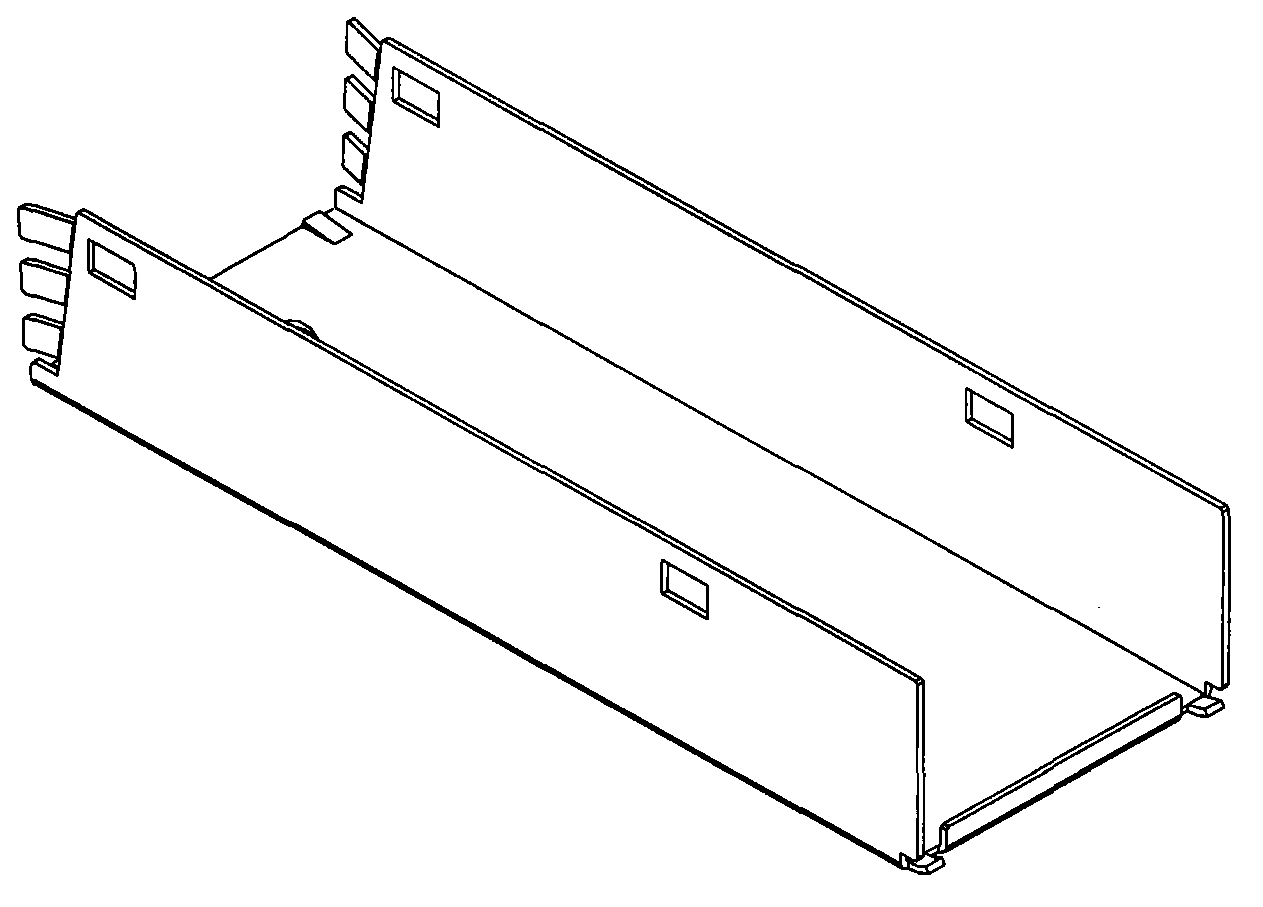

[0027] The invention discloses a small hot-swappable integrated optical transceiver module, which includes an optical transceiver module, and the optical transceiver module is fixed inside the structure body of the small hot-swappable optical transceiver module. The module structure includes a stamped base, a connector spliced and fixed with the base, and a shield cover for the base.

[0028] The inventors have found that the existing small hot-swappable optical transceiver module structure requires a complex die-casting process because the connector and the base are integrally formed, and electroplating treatment is required at the same time. The process is complicated, resulting in a long production cycle and product scrapping The rate is high, which in turn increases the production cost of the product. (For specific process, see Figure 5 ), the small hot-swappable optical transceiver integrated module structure of the present invention includes a base stamped and formed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com