Construction waste recycling method and device

A technology for recycling construction waste, applied in the field of construction equipment, can solve problems such as complex processes, and achieve the effect of simple process and satisfying pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The invention provides a method for recycling construction waste, S1, crushing construction dregs as main materials and auxiliary materials one into granular materials; wherein auxiliary materials one is a viscous material that is solid at room temperature and becomes liquid after heating;

[0056] S2. Thoroughly mix and heat the crushed S1;

[0057] S3, pouring the mixed material of S2 into a frame-type brick mould;

[0058] S4, compacting the brick mold filled with material in S3;

[0059] S5, after the brick mold of S4 is cooled, fasten the upper cover of the hollowed out middle part on the mold;

[0060] S6. The hollow part of the upper cover is the material for smearing and capping.

[0061] Asphalt granules or waste plastic granules are used as auxiliary materials.

[0062] S2 adds auxiliary material 2 during the process of fully stirring and mixing the crushed S1, and the auxiliary material 2 is a flexible strip-shaped fibrous material.

[0063] The second au...

Embodiment 2

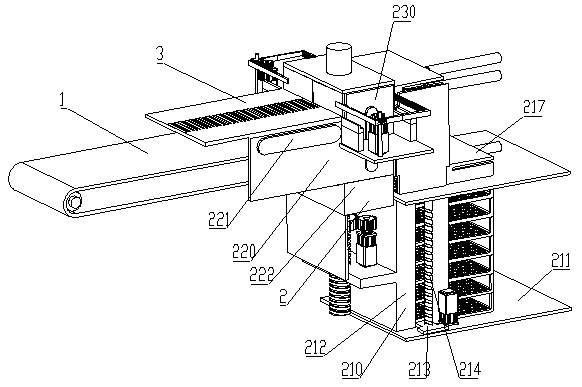

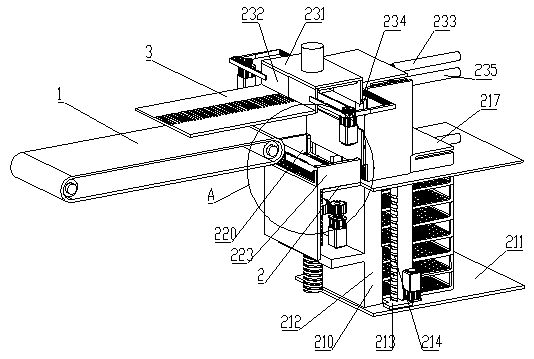

[0074] On the basis of embodiment 1, see Figure 1 to Figure 7 , this solution provides a construction waste recycling device based on the construction waste recycling method, including a feed conveyor belt 1 as a material feeding device, and the discharge port of the feed conveyor belt 1 is connected with the feed port of the forming mechanism 2 , the discharge conveyor belt 3 is set at the discharge port of the forming mechanism 2;

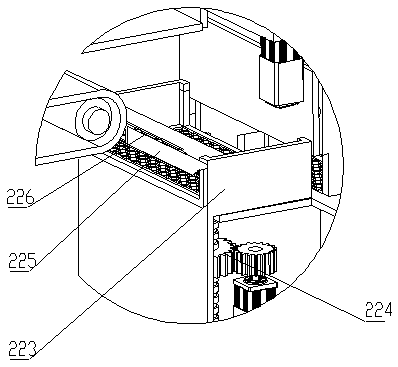

[0075] The molding mechanism 2 includes a mold loading mechanism 210 located at the bottom, a filling mechanism 220 is arranged above the mold loading mechanism 210, and a pressing mechanism 230 is arranged above the filling mechanism 220; The pressing mechanism 230 is provided with a discharge port, and the discharge port communicates with the discharge conveyor belt 3;

[0076] The shell of the filling mechanism 220 is provided with a plurality of electric heating tubes 221 , and the materials in the filling mechanism 220 are heated through t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com