Efficient laminating machine applied to prefabricated slab

A technology of laminating machine and prefabricated board, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of high production cost, unsuitable for prefabricated board, bulky and other problems, and achieve good maintenance work, good attachment effect and processing efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

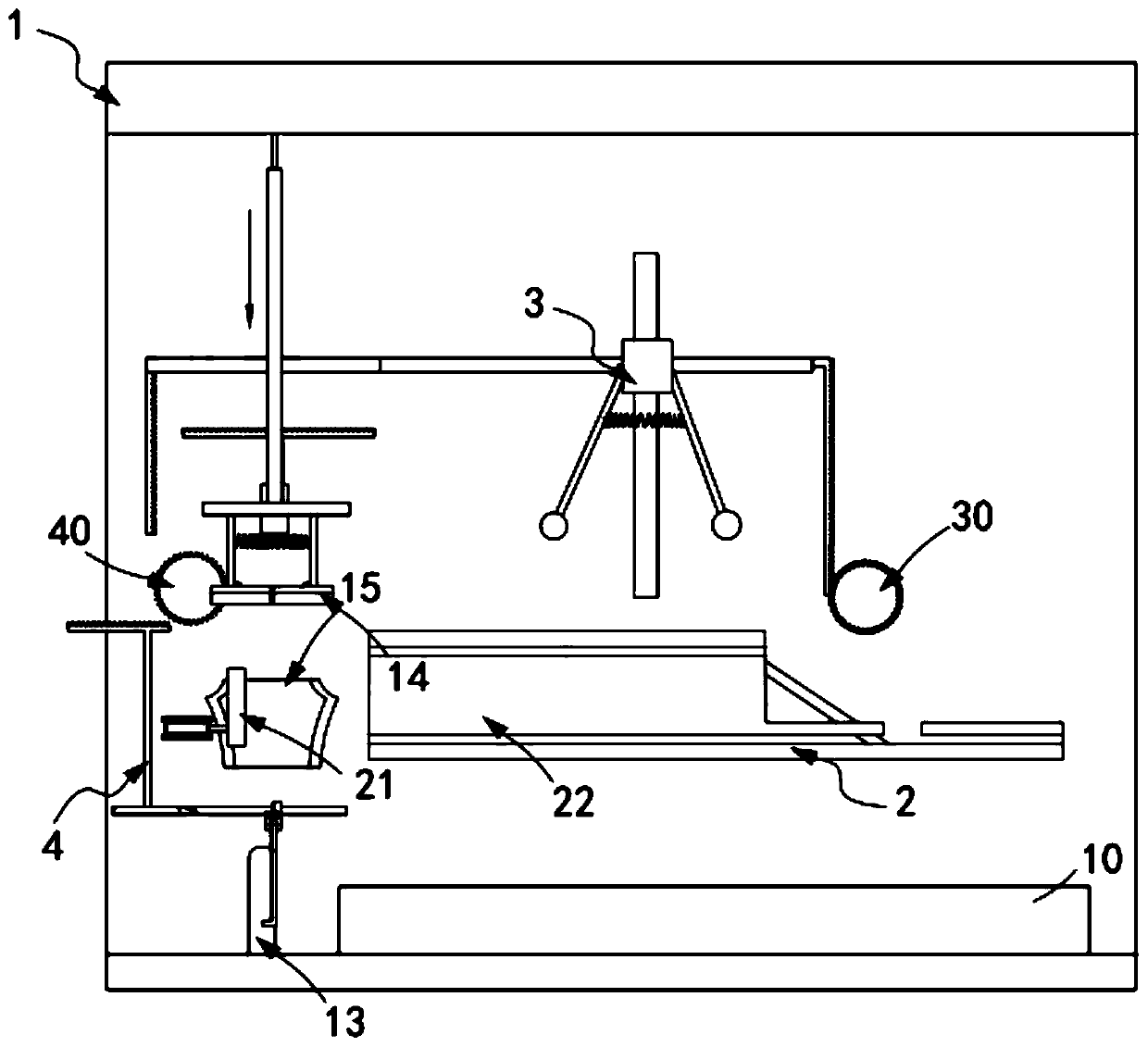

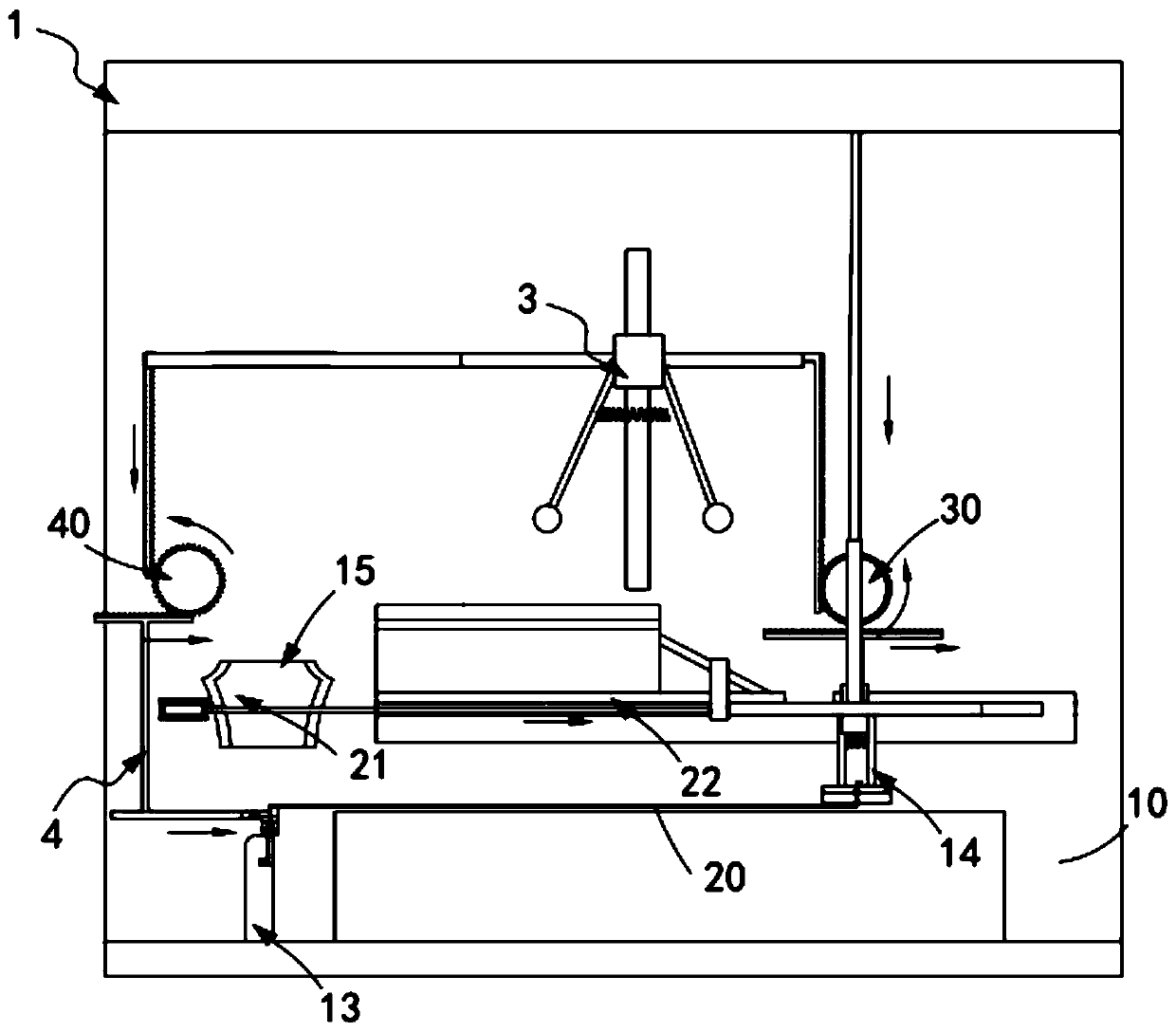

[0079] Such as figure 1 , figure 2 As shown, a high-efficiency laminating machine applied to prefabricated panels, including:

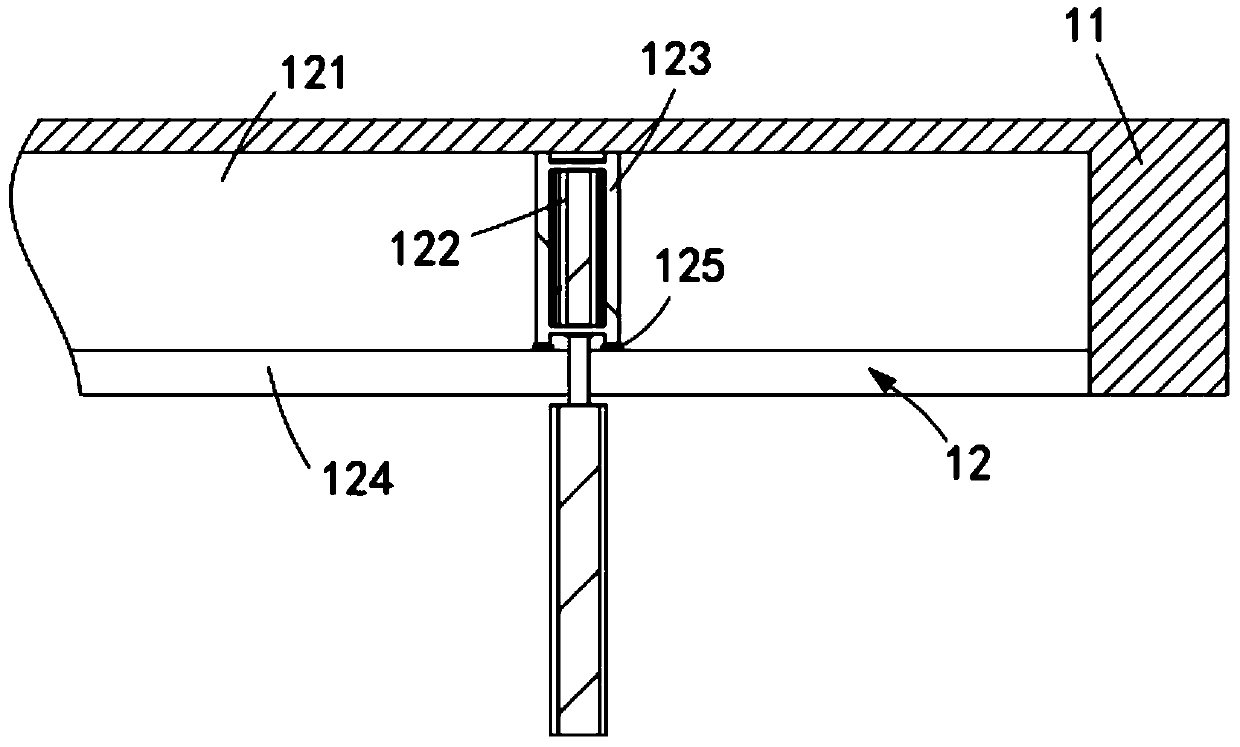

[0080] Lifting mechanism 1, described lifting mechanism 1 comprises frame 11, is installed on the top of described frame 11 and horizontally reciprocatingly slides on described frame 11 the first air pushing assembly 12, is installed under described frame 11 The film release part 13, the clamping assembly 14 fixedly connected to the telescopic end of the first air pushing assembly 12 above the film release part 13, and the clamping assembly 14 installed on the frame 11 and located at the clamping assembly 14 A guide assembly 15 provided on one side, the guide assembly 15 is used to guide the opening and closing of the clamping assembly 14;

[0081] The film covering mechanism 2, the film covering mechanism 2 includes a second air pushing assembly 21 installed on the frame 11 and arranged horizontally and a sliding assembly 22 arranged along the hor...

Embodiment 2

[0133] Such as Figure 9 , Figure 11 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

[0134] further, such as Figure 8 As shown, the laminating mechanism 3 includes:

[0135] Lifting plate 31, the lifting plate 31 slides up and down on the frame 11;

[0136] A support block 32, the support block 32 is fixedly arranged at the central position of the lifting plate 31;

[0137] Pressing roller unit 33, said pressing roller unit 33 is provided with two groups and arranged symmetrically along the midline on the length of said support block 32, which includes a swing plate 331 rotatably arranged on said support block 32 and fixedly arranged on said support block 32. the pressure roller a3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com