A deep-sea high-speed towing safety control system

A safety control, high-speed technology, applied in the safety control strategy and composition, deep-sea high-speed towing safety control system field, can solve the problems of higher reliability requirements, increased possibility of ballasted towed body, increased tow cable tension, etc., to achieve improved Recycling reliability, reducing the risk of bottoming out, and ensuring the safety of the towline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below with reference to the accompanying drawings and examples.

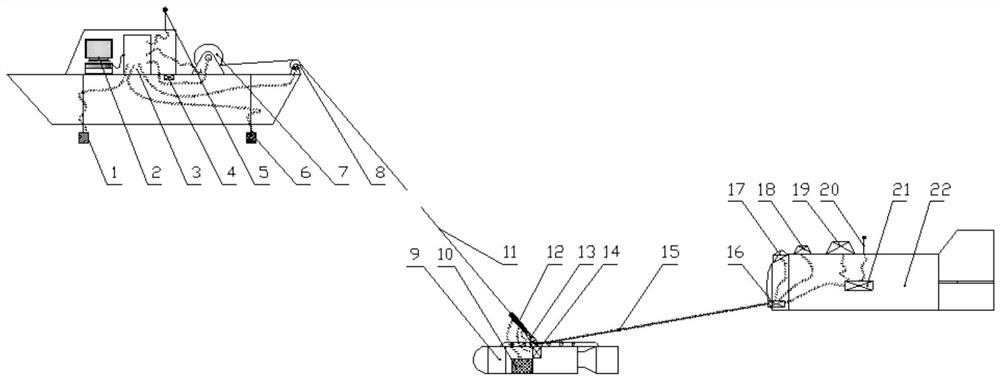

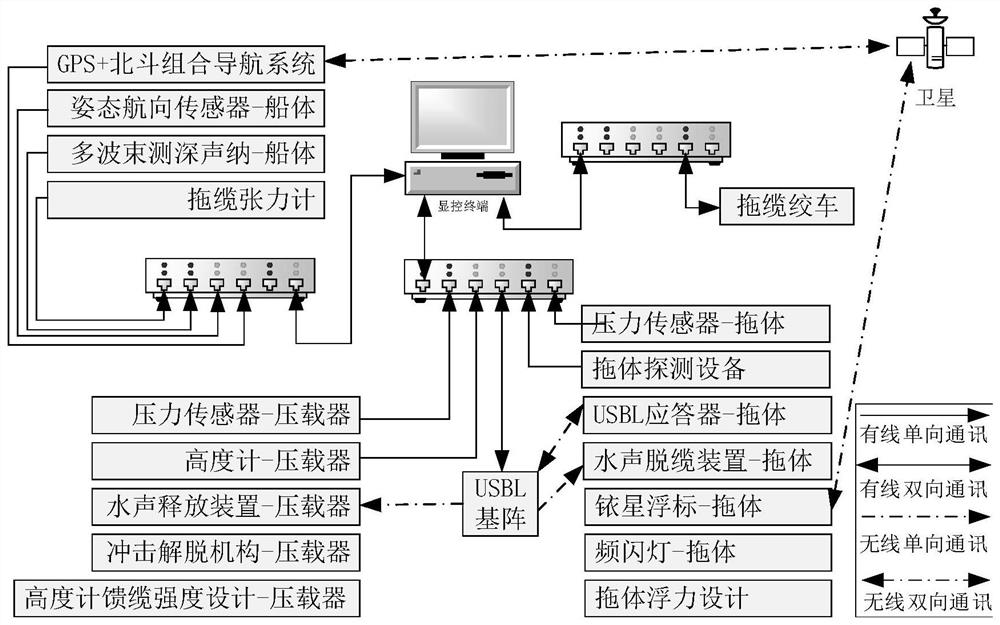

[0020] as attached figure 1 As shown, the present invention provides a deep-sea high-speed towing safety control system, the system includes a display and control terminal 2, a multi-beam sounding sonar 1, a control cabinet 3, an attitude and heading sensor 4, a GPS+Beidou integrated navigation system 5, and a USBL array 6. Tow cable 11, tow cable winch 7, tow cable tension gauge 8, pressure sensor 9, altimeter 10, data energy conversion bearing cabin 12, underwater acoustic release device 13, impact release mechanism 14, umbilical cable 15, cable release device 16. USBL transponder 17, underwater acoustic communication machine 18, strobe light 19, iridium star buoy 20, tow body detection equipment 21, detection tow body 22 and other equipment, with front terrain detection and early warning, ballast height monitoring and early warning from the bottom , bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com