Fully automatic bar conveying system

A conveying system and fully automatic technology, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of not being able to achieve automatic online grinding operations, and cannot achieve overall linkage, and achieve a high degree of automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is further illustrated below in conjunction with the accompanying drawings and specific examples, and these examples are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

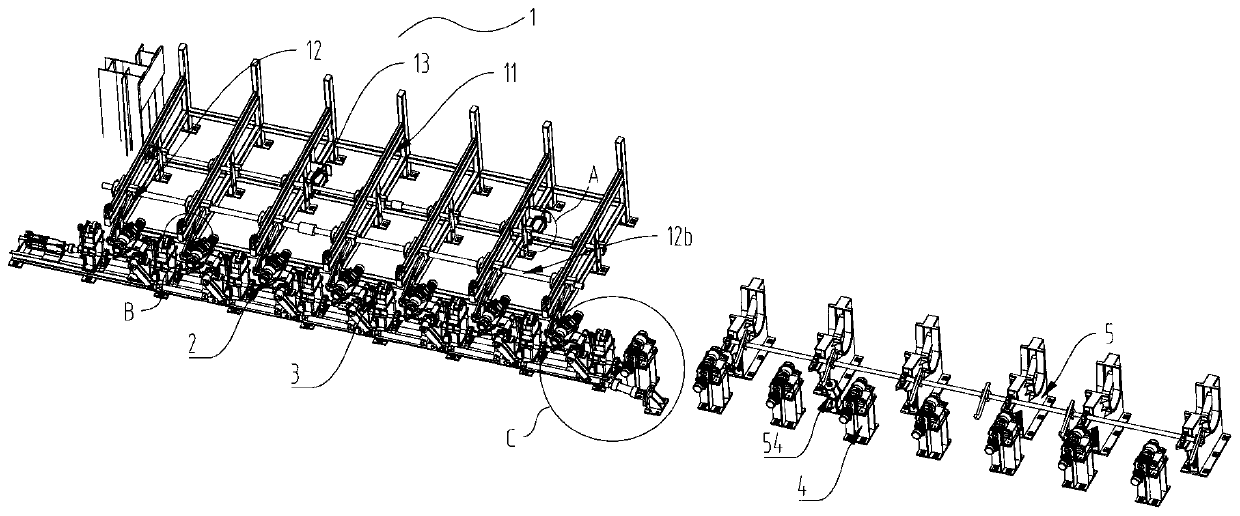

[0025] A fully automatic bar conveying system, such as attached figure 1 As shown, it includes a feeding platform 1, a lifting roller table 2, a counter-rotating roller table 3, a fixed roller table 4, and a material collecting device 5.

[0026] In this embodiment, in order to optimize the layout, the lifting roller table 2, the counter-rotating roller table 3, and the fixed roller table 4 are arranged horizontally, the feeding platform 1 and the counter-rotating roller table 3 are arranged vertically, and the collecting device 5 and the fixed roller table are arranged vertically. The road 4 adopts vertical arrangement, and the feeding platform 1 and the collecting device 5 are located on the same side of the lifting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com