Stabilization treatment process of precipitation hardening type nickel-based high-temperature alloy

A nickel-based superalloy, precipitation hardening technology, applied in the field of heat treatment of nickel-based superalloy, to achieve the effect of improving comprehensive performance, excellent room temperature, and good matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A stabilization treatment process for a precipitation-hardening nickel-based superalloy, comprising the following steps:

[0033] 1) Heat the heat treatment furnace to 600°C;

[0034] 2) loading the precipitation-hardening nickel-based superalloy in the solution-treated state into the heat treatment furnace in step 1);

[0035] 3) After heating the nickel-based superalloy in step 2) to 990° C. for 1.5 hours, start timing, hold the temperature for 2 hours, and cool it out of the furnace in air to obtain a stabilized nickel-based superalloy.

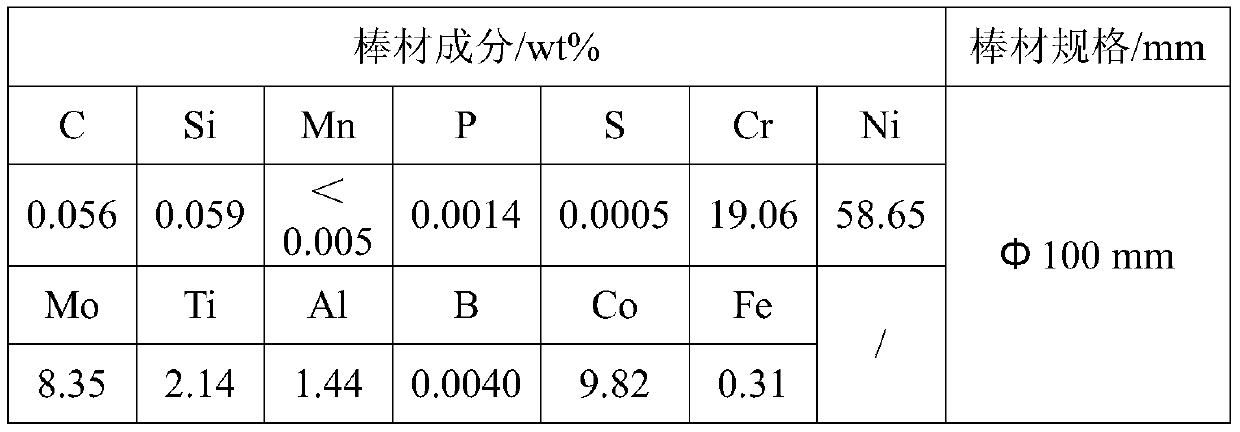

[0036] The precipitation-hardening nickel-based superalloy in the solution-treated state in step 2) of this embodiment is a rod, and the specifications and components of the rod are shown in Table 1 below.

[0037] Table 1 Example 1 Nickel-based superalloy bar composition and specification

[0038]

Embodiment 2

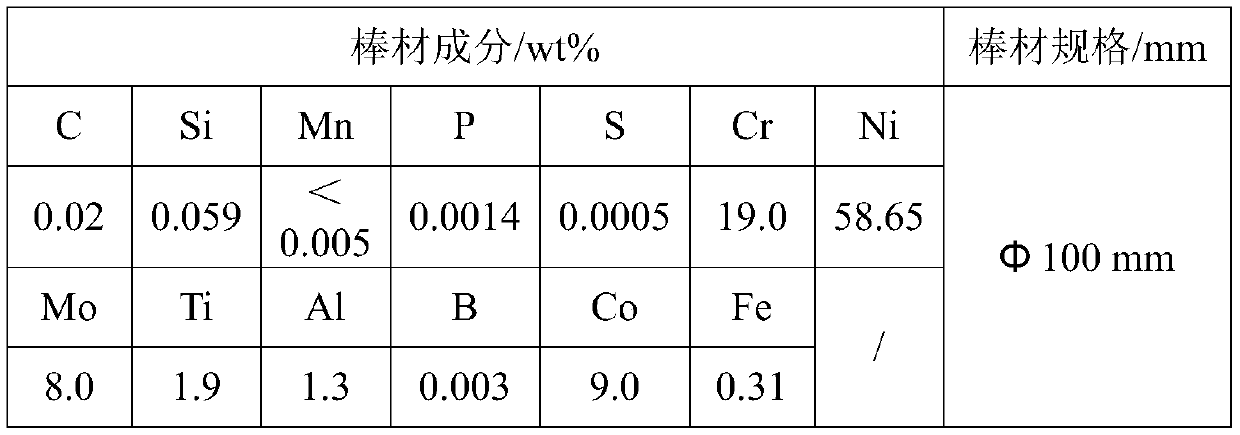

[0040] A stabilization treatment process for a precipitation-hardening nickel-based superalloy, carried out according to the method in Example 1, the difference is that:

[0041] 1) Heat the heat treatment furnace to 650°C;

[0042] 2) loading the precipitation-hardening nickel-based superalloy in the solution-treated state into the heat treatment furnace in step 1);

[0043] 3) After heating the nickel-based superalloy in step 2) to 1020° C. for 2 hours, start timing, keep the temperature for 1.5 hours, and take it out of the furnace for air cooling to obtain a stabilized nickel-based superalloy.

Embodiment 3

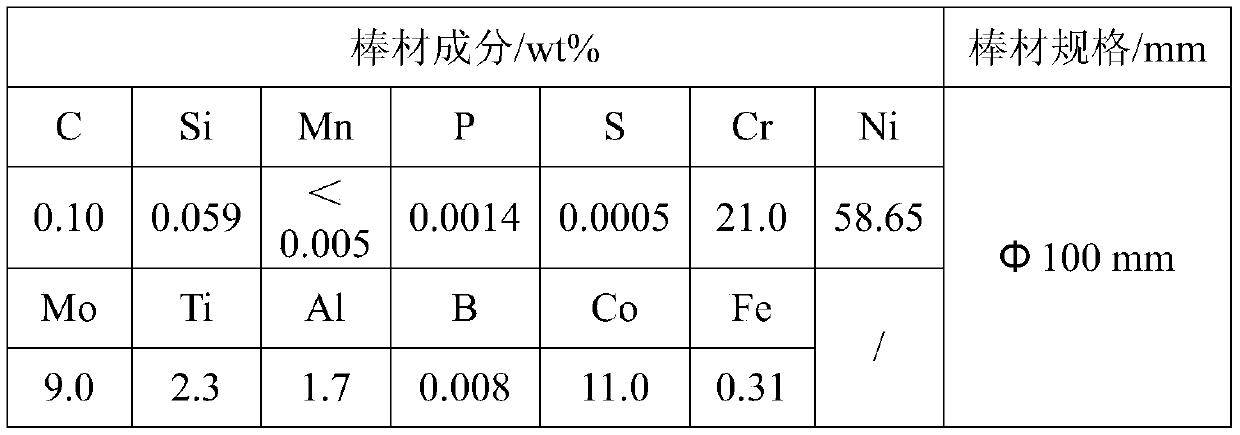

[0045] A stabilization treatment process for a precipitation-hardening nickel-based superalloy, comprising the following steps:

[0046] 1) Heat the heat treatment furnace to 500°C;

[0047] 2) loading the precipitation-hardening nickel-based superalloy in the solution-treated state into the heat treatment furnace in step 1);

[0048] 3) After heating the nickel-based superalloy in step 2) to 970° C. for 1 hour, start timing, keep the temperature for 1 hour, take it out of the furnace and air-cool to obtain a stabilized nickel-based superalloy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com