Electrical automation equipment mounting base

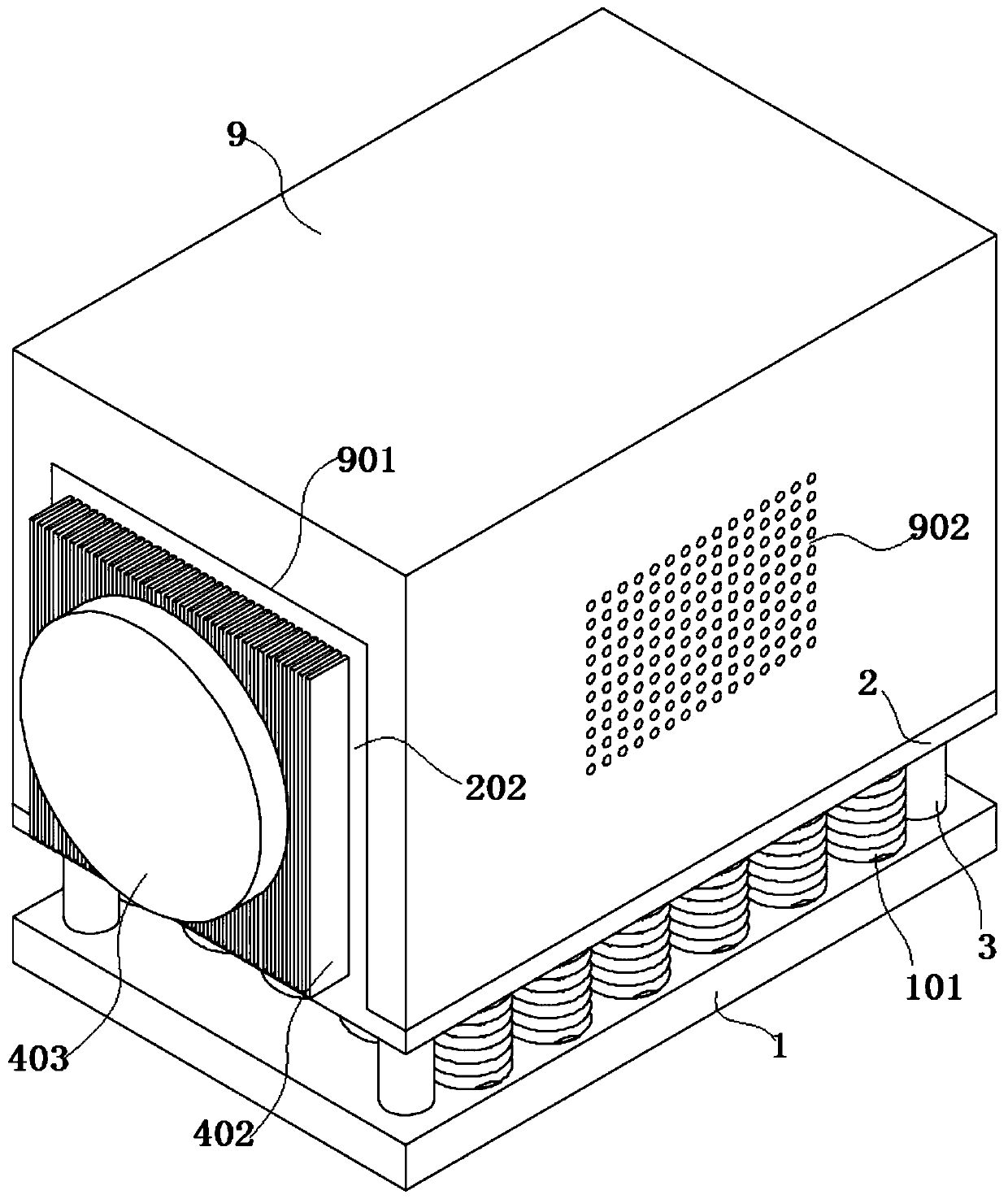

A technology for electrical automation and equipment installation, which is applied to the structural parts of electrical equipment, electrical equipment shells/cabinets/drawers, electrical components, etc. Install the practicability of the base and other issues to achieve the effect of increasing the protection effect, avoiding excessive temperature, and ensuring the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

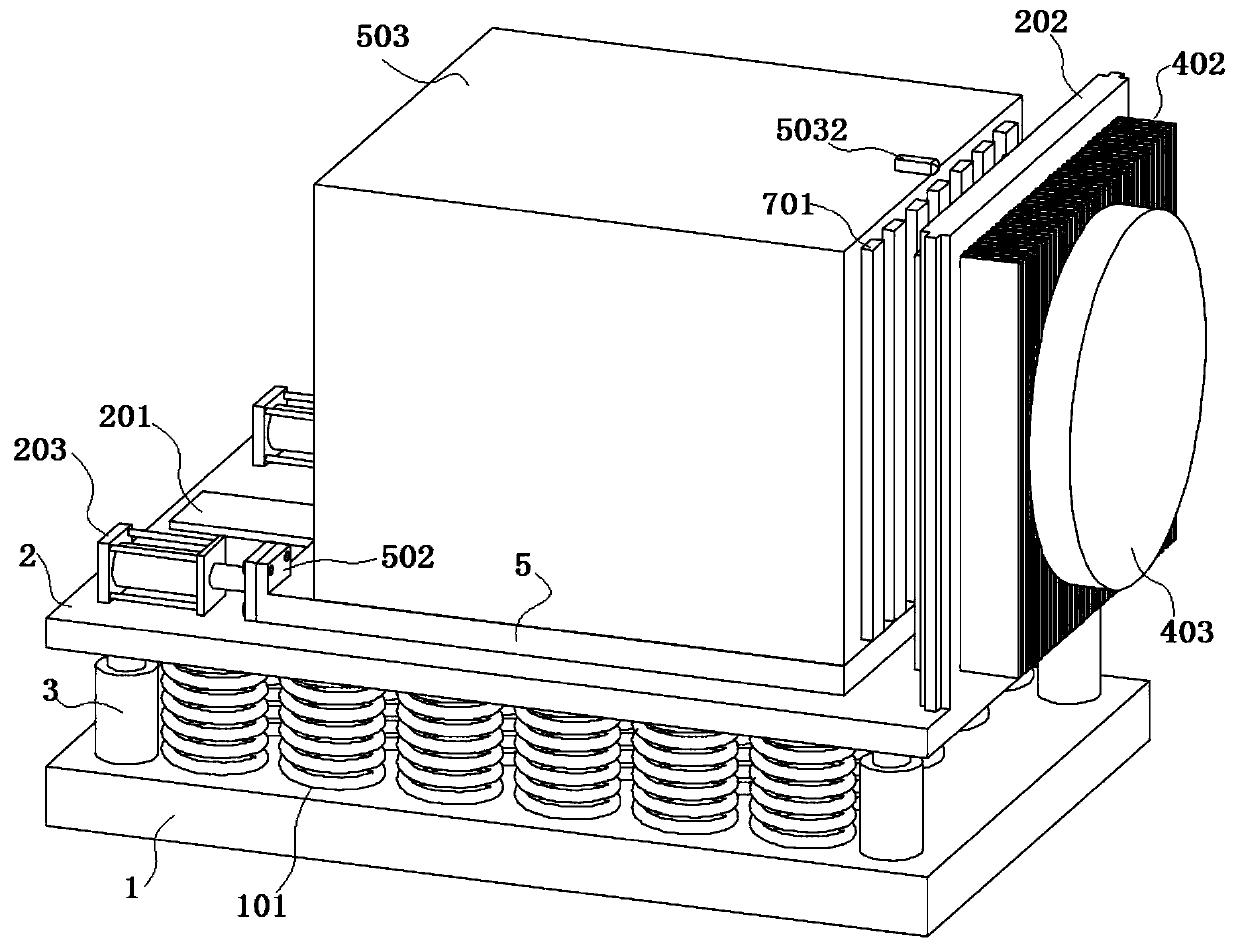

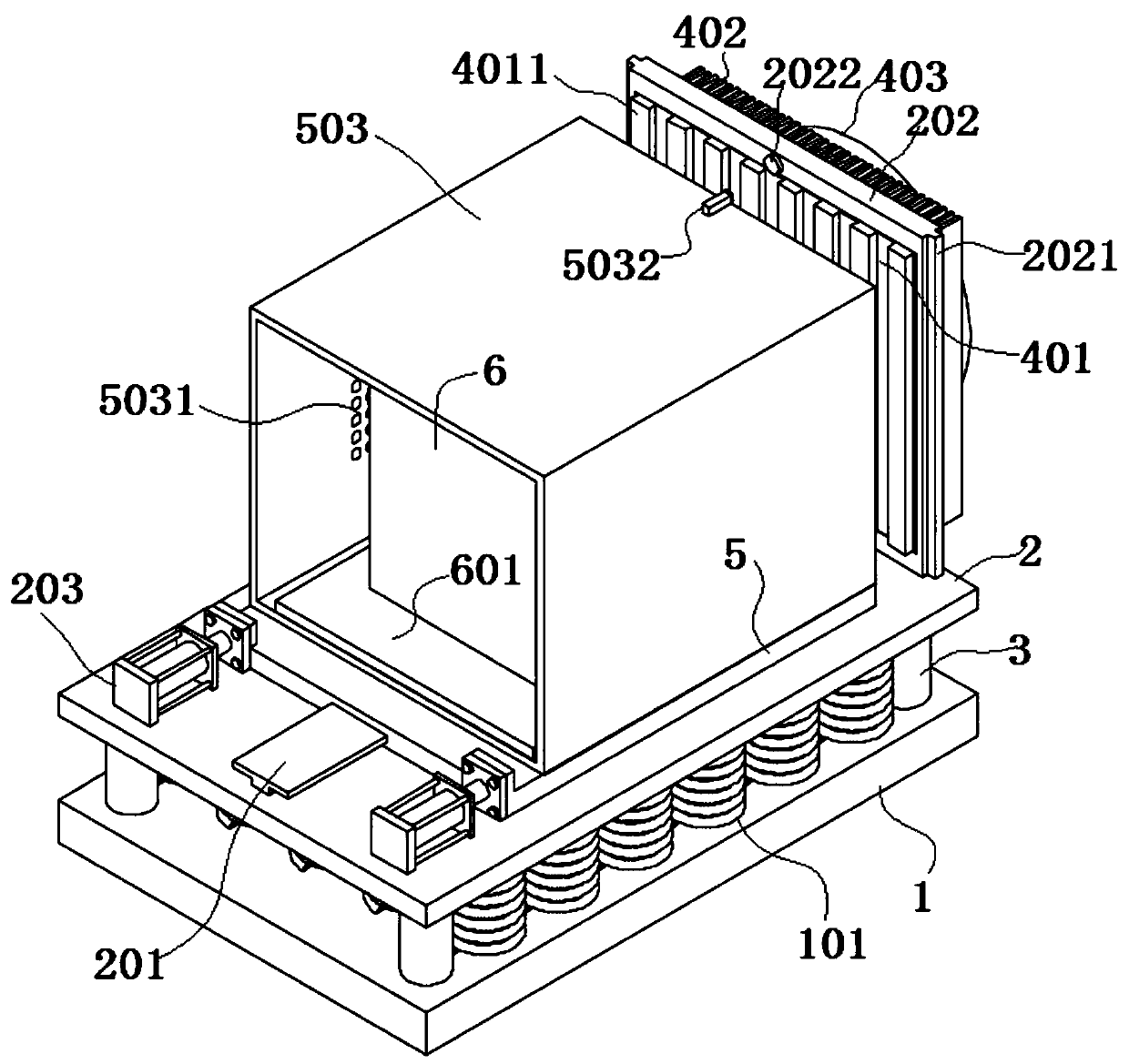

[0046] Embodiment 1: This embodiment is a method of using the installation base of electrical automation equipment: when the electrical equipment body 6 is running in a low-frequency state, the temperature sensor senses the temperature data information of the electrical equipment body 6, and when the temperature data is lower than the set threshold , the controller controls the cylinder 203 to be in a contracted state; the electrical equipment body 6 is radiated through the second cooling fan 8;

[0047] When the electrical equipment body 6 is running in a high-frequency state, and the temperature sensor senses that the temperature data information of the electrical equipment body 6 exceeds the set threshold, the temperature sensor transmits the signal to the controller, and the controller controls the extension of the cylinder 203 to push the base 5 to slide to the right , make the rectangular groove 701 engage with the rectangular protrusion 4011 to connect the second heat co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com