Butt joint equipment, waste liquid collecting and treating system and waste liquid treating method

A waste liquid collection and treatment system technology, which is used in extraction and pumping systems, hypodermic injection devices, suction containers, etc., can solve the problems of increased manufacturing cost, easy to be affected by scale, complicated installation, etc., and achieves enhanced sealing performance. Strength, will not affect the detection accuracy, the effect of simplifying the installation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The following descriptions of the various embodiments refer to the accompanying drawings to illustrate specific embodiments in which the present invention can be implemented. The directional terms mentioned in the present invention, such as "up", "down", "front", "back", "left", "right", "inside", "outside", "side", etc., are for reference only The orientation of the attached schema. Therefore, the directional terms used are used to illustrate and understand the present invention, but not to limit the present invention.

[0073] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings.

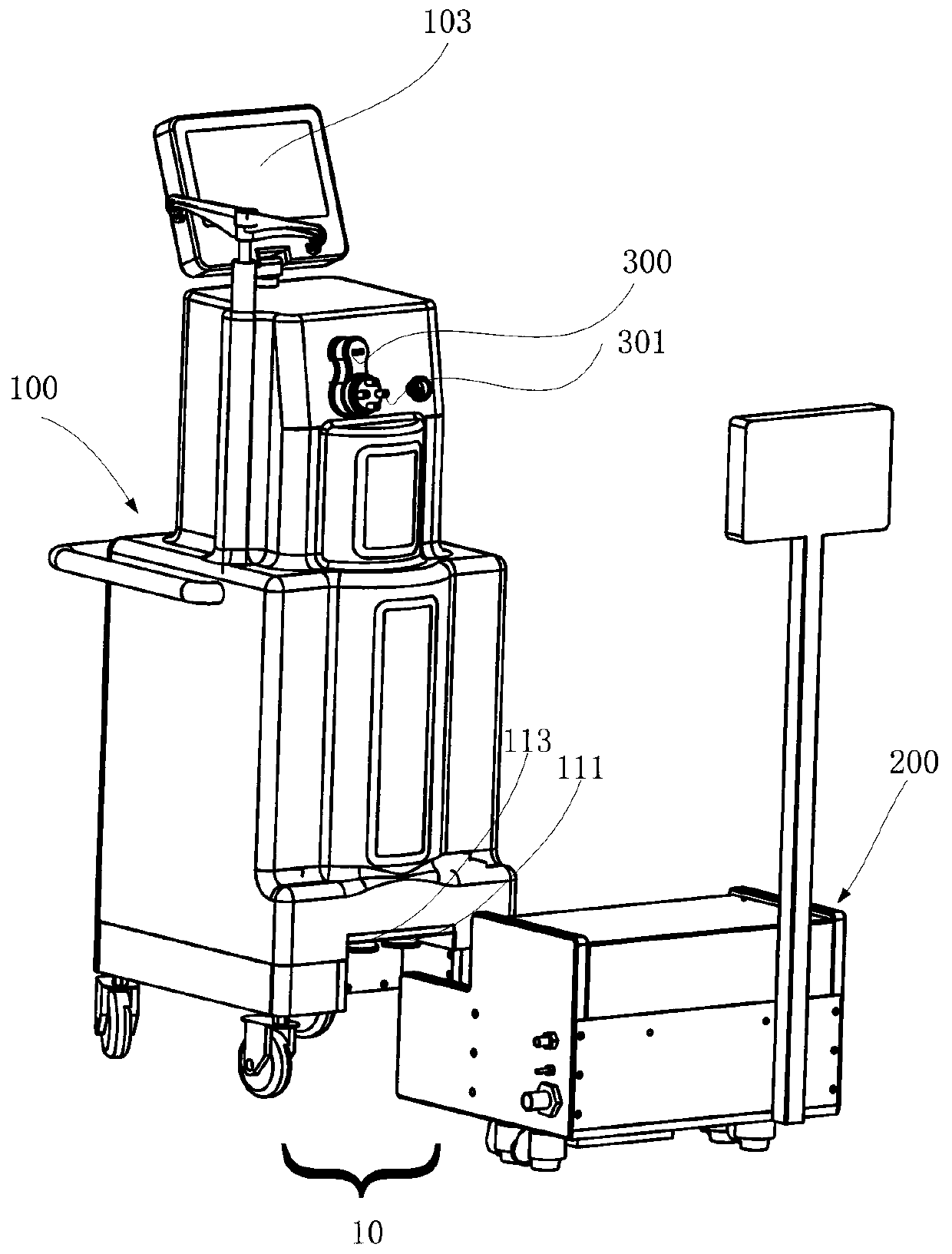

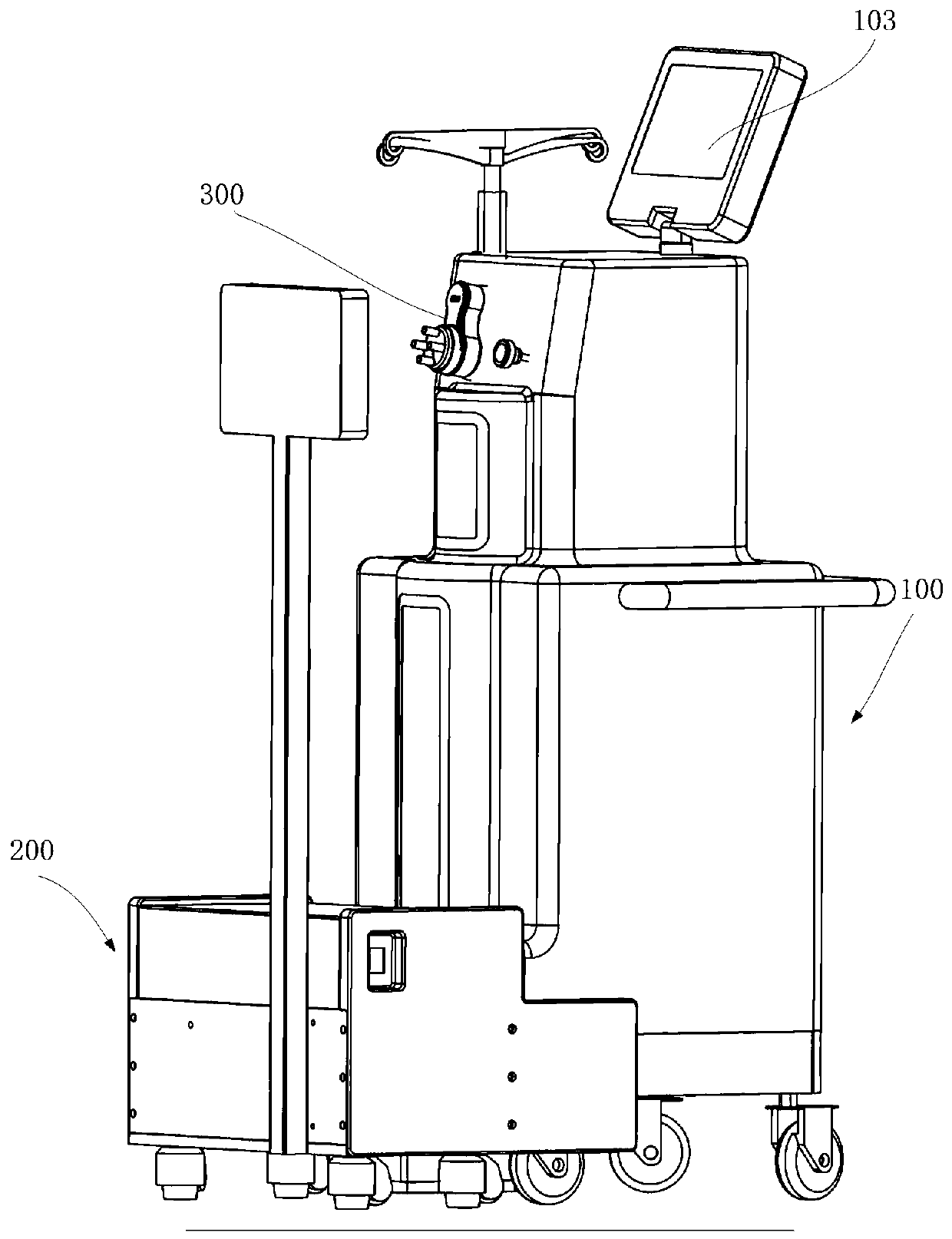

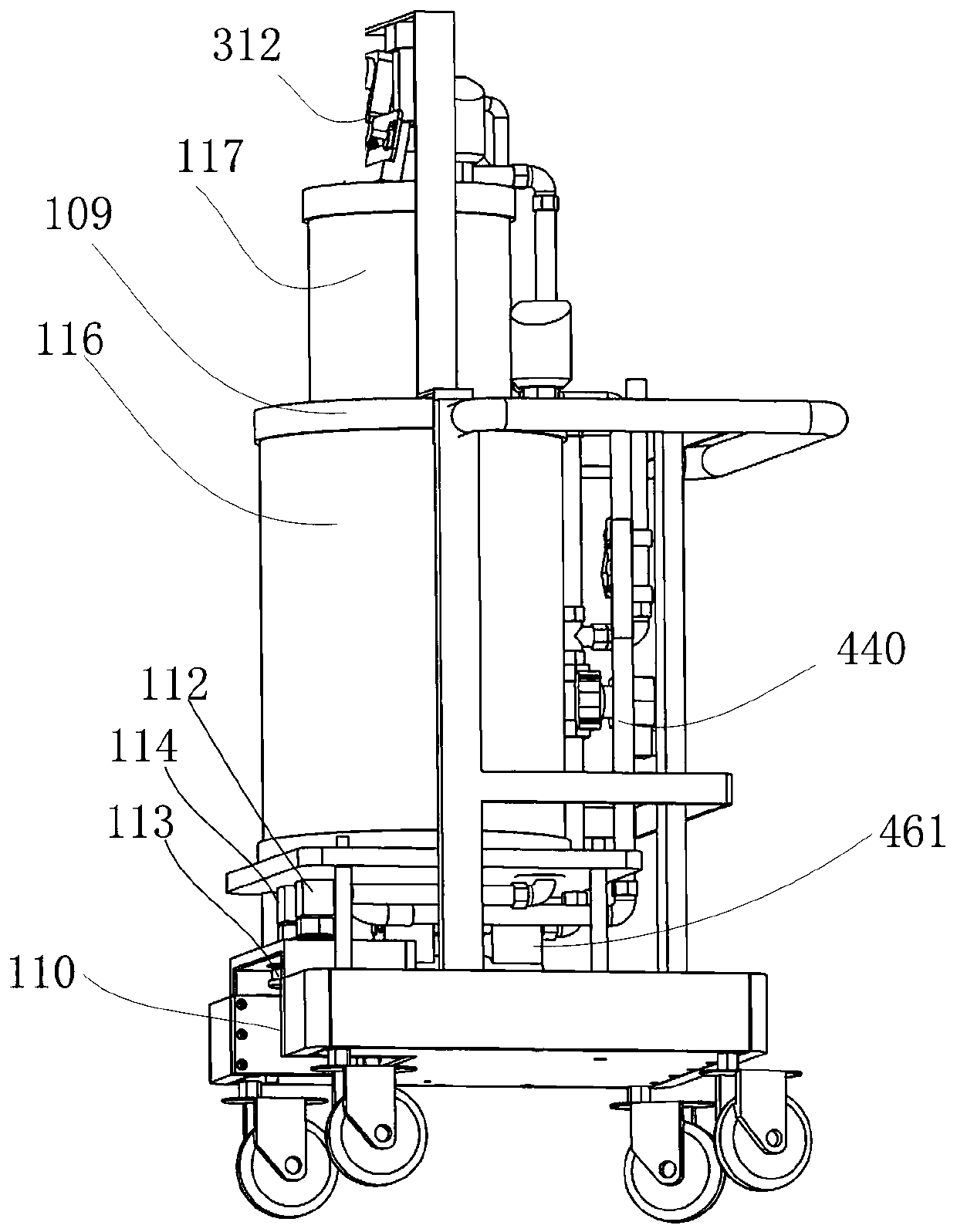

[0074] Such as Figure 1-Figure 5 as shown, figure 1 and figure 2 A waste liquid collection and treatment system 10 is shown, the system includes a waste liquid collection device 100 and a docking device 200, figure 1 The waste liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com