Electrode cap replacement machine

An electrode cap and replacement machine technology, applied in resistance welding equipment, auxiliary devices, auxiliary welding equipment and other directions, can solve the problems of cumbersome and time-consuming disassembly process, complex structure, inconvenient control, etc., to achieve compact structure, reasonable structure layout, and convenient control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

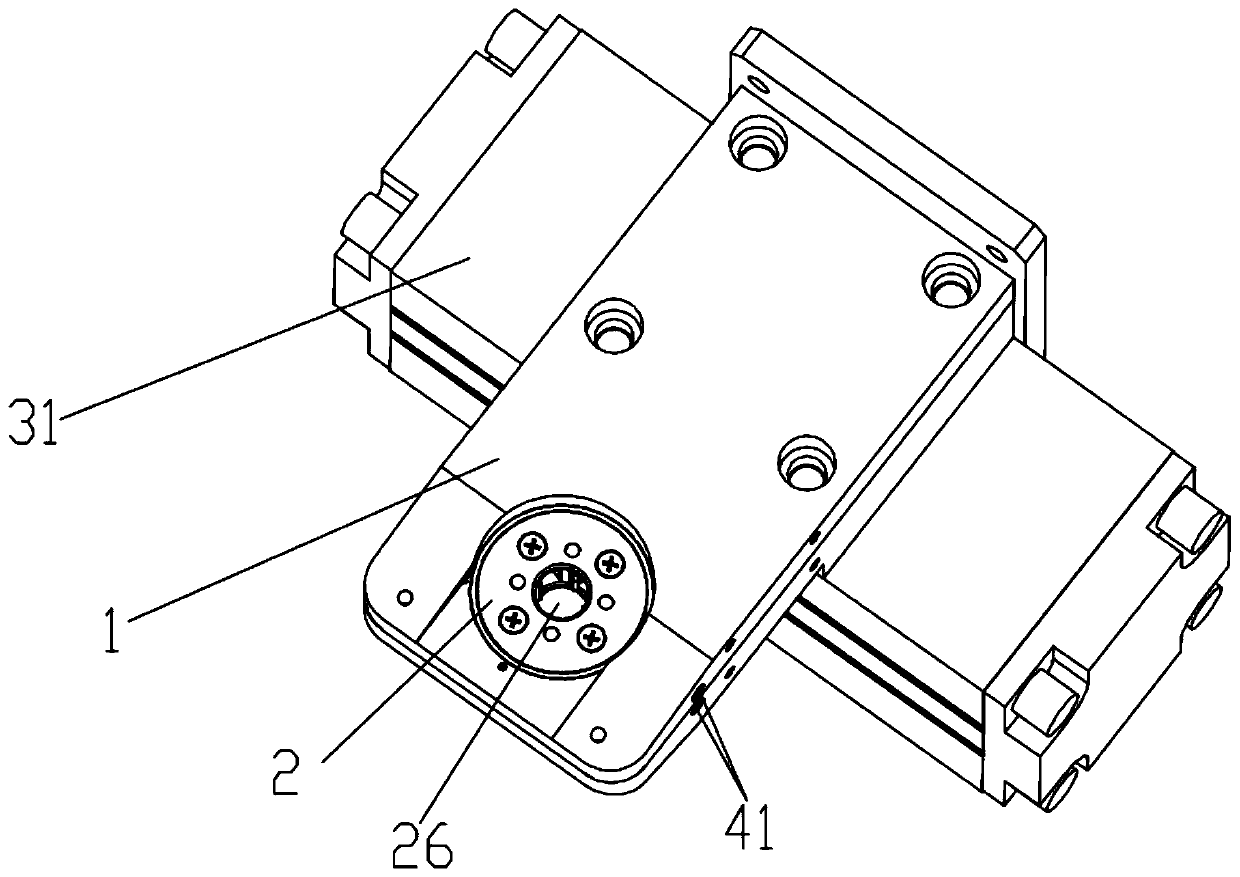

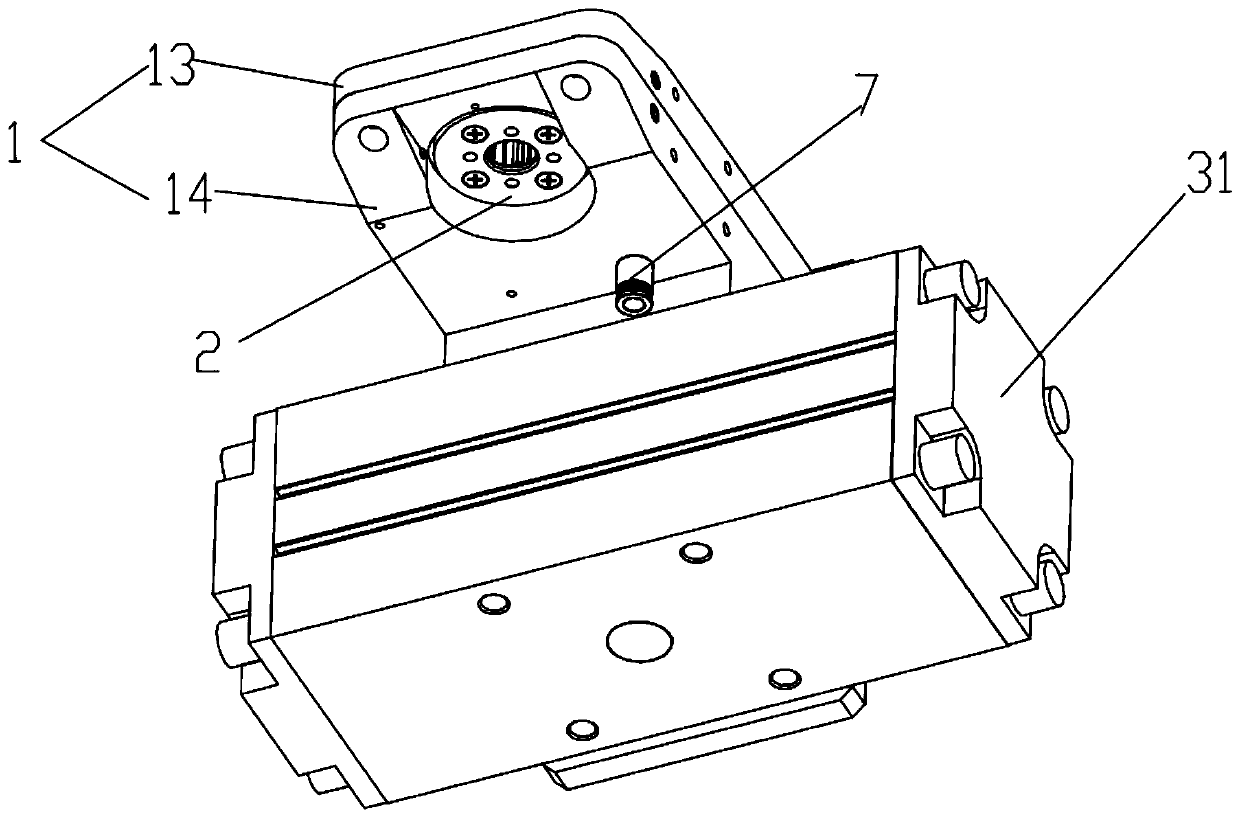

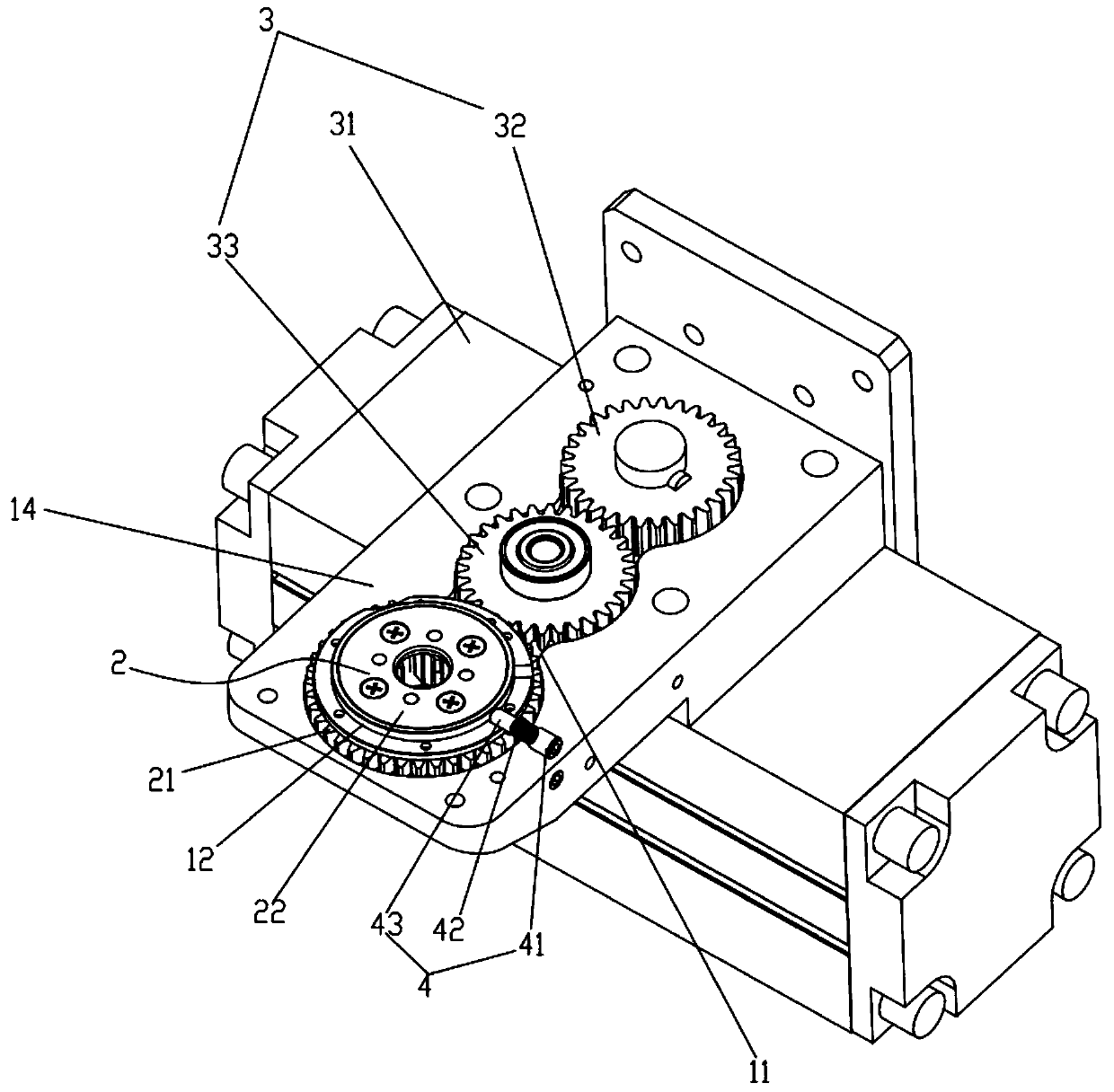

[0030] Such as Figure 1-6 As shown, the electrode cap replacement machine includes a housing 1, a cap removal head 2, a driving device 3 and a damper 4. The housing 1 is provided with an accommodation chamber 11, and the cap removal head 2 is movable in the accommodation chamber 11. Head 2 comprises decapping gear 21, claw cover 22 and four claws 23, and claw cover 22 comprises upper cover 221 and lower cover 222, and upper cover 221 and lower cover 222 are positioned at the both sides of decapping gear 21 respectively and pass Four connecting pins 24 are fixedly connected together, the cap removal gear 21 is located between the upper cover 221 and the lower cover 222 and can rotate relative to the claw cover 22, the cap removal gear 21 is a hollow ring structure, and the four claws 23 are along the The circumferential direction is evenly placed in the inner ring of the cap removal gear 21, and the rear ends of each claw 23 are respectively hinged with the inner wall of the c...

Embodiment 2

[0042] On the basis of embodiment 1 technical scheme, make following improvement:

[0043] Such as Figure 7 As shown, an electrode cap detector 5, an upper electrode cap feeder 61 and a lower electrode cap feeder 62 are added to the housing 1 of the electrode cap replacement machine, wherein the upper electrode cap feeder 61 and the lower electrode cap feeder 62 are respectively It is installed on the left and right sides of the housing 1, and is arranged side by side with the cap removal head 2 horizontally. Among them, the upper electrode cap feeder 61, the lower electrode cap feeder 62, and the electrode cap detector 5 can adopt the applicant’s prior application and disclosed technology, or can use the existing technology in this field, and its detailed structure will not be discussed herein. repeat.

[0044] Compared with the prior art, the electrode cap replacement machine of the present invention has the following advantages: ① A longitudinal clamping blade 231 is arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com