Aseptic bin

A sterile warehouse and integrated technology, applied in the field of sterile warehouses, can solve the problems of low mechanical strength, unfavorable sterile environment, and easy breeding of bacteria in the sterile warehouse, and achieve the effects of improving mechanical strength, reducing its own weight, and increasing strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

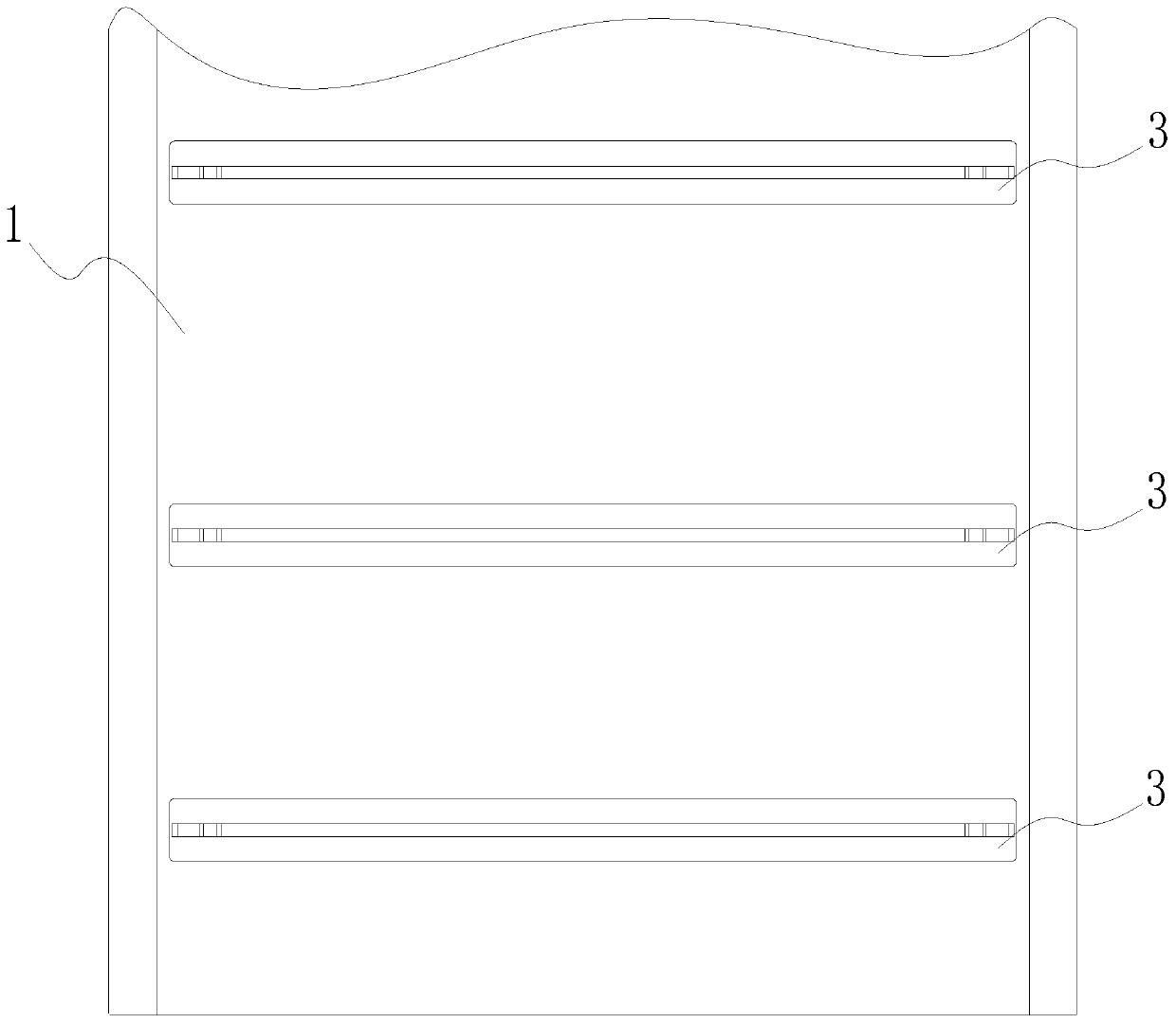

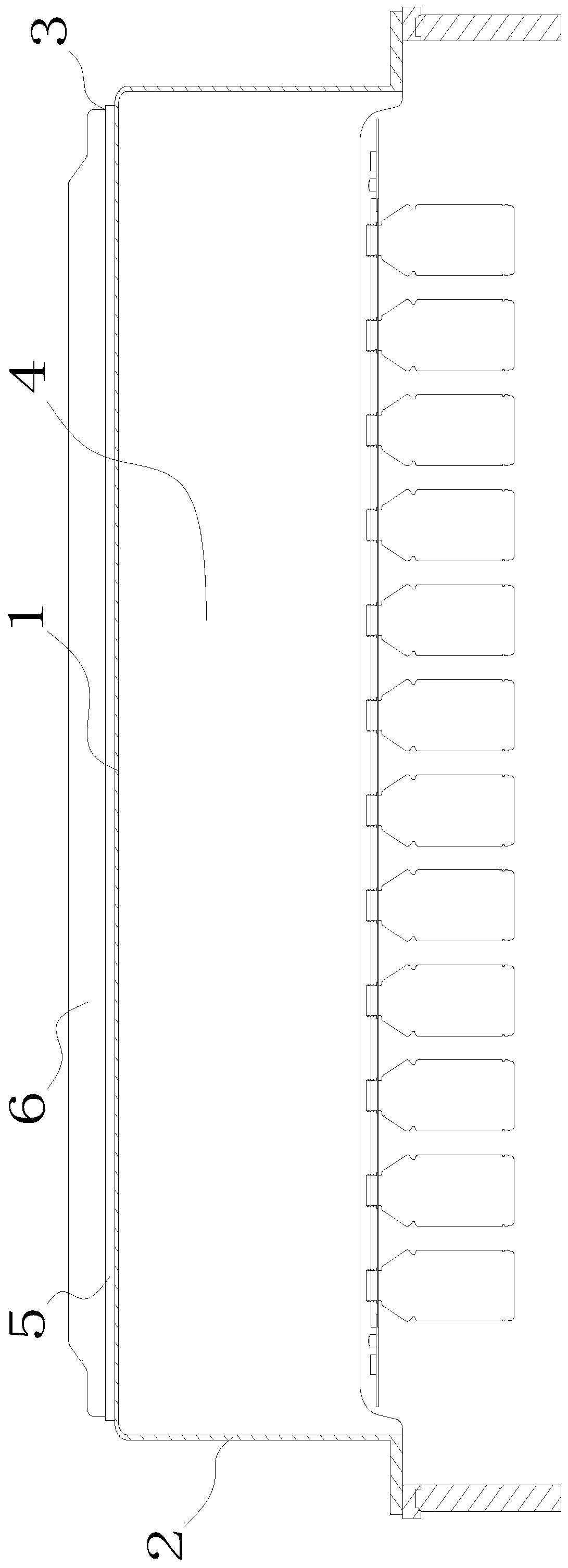

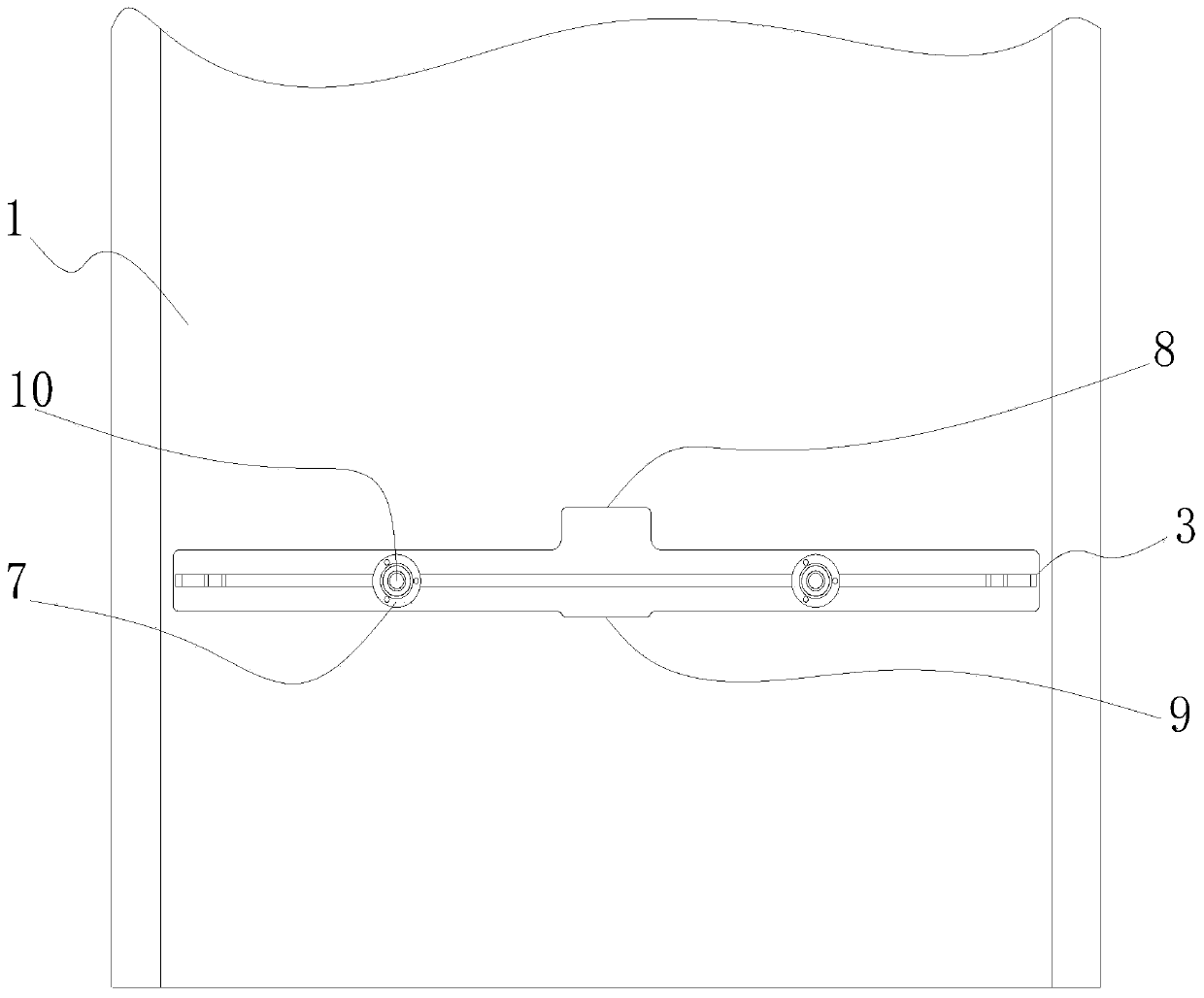

[0028] Such as figure 1 , 2 Shown, the first embodiment of the present invention.

[0029] The aseptic warehouse includes a top part 1 , a supporting part 2 and a reinforcement part 3 . Both the top part 1 and the support part 2 are made of sheet metal, the support part 2 is located at one side of the top part 1 , the support part 2 is perpendicular to the top part 1 . The top part 1 and the support part 2 are closely connected, and a storage cavity 4 of a semi-closed structure is formed between them. The reinforcing member 3 has an integrated structure and is in the shape of a strip as a whole. It includes a connection part 5 and a reinforcement part 6; The reinforcement part 6 is located on the connection part 5 and the reinforcement part 6 is perpendicular to the connection part 5, the reinforcement part 6 and the connection part 5 are integrated, the connection part 5 is fixed on the top part 1 and the reinforcement part 3 is in the width direction of the storage cavity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com