A kind of medical cationic polymer biopolymer material and its preparation method and application

A cationic polymer, biopolymer technology, applied in the field of medical cationic polymer biopolymer materials and preparation, cationic biopolymer materials and preparation fields, can solve problems such as self-dissolution failure, achieve excellent stability and mild reaction conditions , the effect of increasing the degradation half-life or dissolution time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

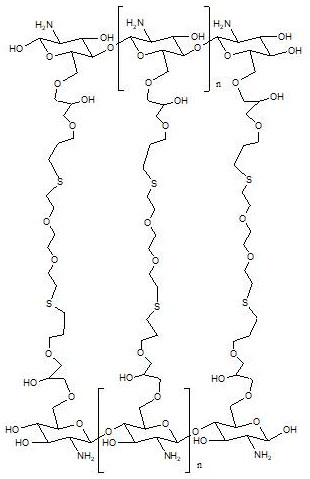

[0068] The present invention also provides the preparation method of the medical cationic polymer biopolymer material shown in above-mentioned formula (1), comprises the steps:

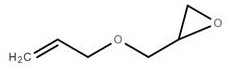

[0069] S1, the chitin-based polymer material and the compound 1 having the following formula (2) undergo a ring-opening addition reaction to obtain a compound 3 having the following formula (4); the specific reaction process is as follows:

[0070] First, the chitin biopolymer material is dissolved in water or an acidic aqueous solution (pH is acidic) to obtain a chitin biopolymer solution, and then according to the amount of the primary hydroxyl group in the chitin biopolymer material: the substance of compound 1 The ratio of the amount is 1:(0.1~2) (preferably 1:1.5), add compound 1 to the chitin biopolymer solution, stir at room temperature for 1~3 days, preferably 3 days; after the reaction is completed, stir rapidly , slowly added ethanol solution, compound 3 was precipitated. Filter, wash with ...

Embodiment 1

[0095] According to the amount of the substance of the primary hydroxyl group in the chitosan acetate: the ratio of the amount of the substance of compound 1 (allyl glycidyl ether) as shown in formula (7) is 1: 1.5, take the refined chitosan B Acetate (deacetylation degree: more than 95%) and allyl glycidyl ether (for example: chitosan acetate 20g, allyl glycidyl ether 21.2g), stand-by;

[0096] Chitosan acetate is added in proportion to purified water (corresponding to 600ml) and stirred for dissolution to obtain a chitosan acetate solution with a mass concentration of 3%. Add the weighed allyl glycidyl ether and stir at room temperature for 24 hours. The feed solution was freeze-dried for 2 days, and after drying, it was taken out and washed 3 times with absolute ethanol, each time with 200 ml of absolute ethanol, stirred for 10 min, then filtered and dried to obtain compound 3.

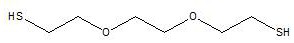

[0097] According to the ratio of the amount of the substance of the amino group in the obtained...

Embodiment 2

[0105] The difference between this embodiment and embodiment 1 is:

[0106] Compound 1 adopts the compound shown in formula (6): (1,2-epoxy-5-hexene).

[0107] Others refer to the method of Example 1 to obtain a high-molecular polymer sponge, which is designated as sample A2.

[0108] The chemical structural formula of the compound 3 obtained in the present embodiment 2 is specifically:

[0109]

[0110] One of the chemical structural formula of the sample A2 that present embodiment finally makes is:

[0111]

[0112] Also according to the reaction principle, sample A2 may also contain, the two ends of Y-containing compound 2 (2,2'-(1,2-ethylenedioxy) diethanethiol) are respectively connected with the primary hydroxyl groups at different positions. Compounds containing other linking structures of X compound 1 (1,2-epoxy-5-hexene).

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com