Stiffened polypropylene resin material

A technology of polypropylene resin and polypropylene pellets, which is applied in the field of rigid polypropylene resin materials, can solve the problems of low impact strength, poor longitudinal tear performance, and unstable shrinkage of polypropylene resin, and achieve improved impact strength and Longitudinal tear resistance and shrinkage stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention are described in detail below. No specific techniques or conditions are indicated in the examples, and the techniques or conditions described in the literature in this field or the product specification are carried out. The reagents or instruments used were not indicated by the manufacturer, and they were all commercially available conventional products.

[0019] Implementation column 1

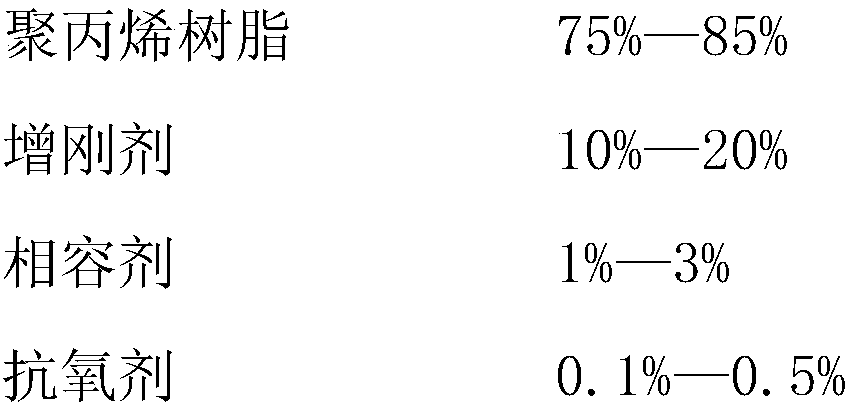

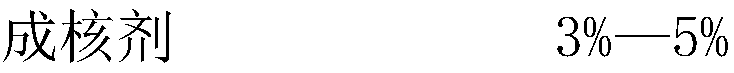

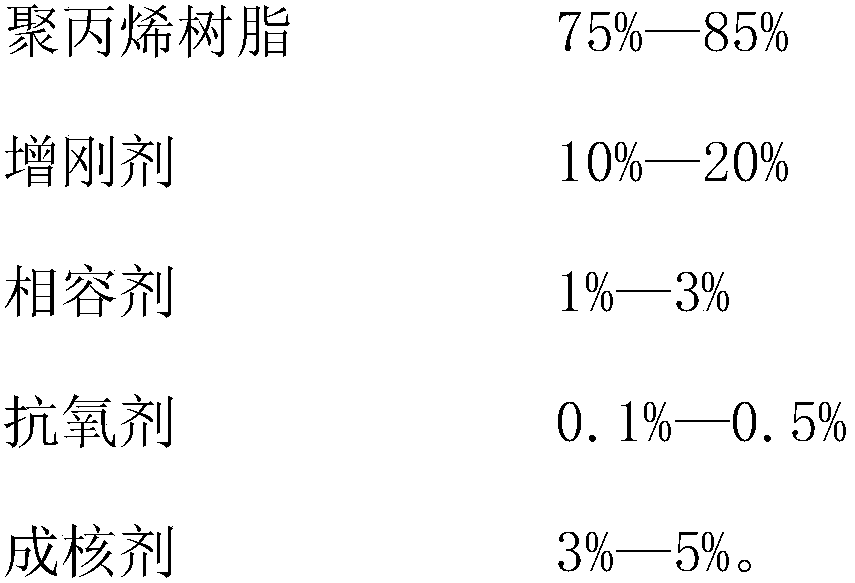

[0020] A kind of rigid polypropylene resin material, it is made up of the raw material of following mass parts:

[0021] 80% of polypropylene resin, 12.9% of stiffening agent, 2% of compatibilizer, 0.1% of antioxidant, and 5% of nucleating agent. Wherein the ratio of the polypropylene pellets to the polypropylene powder is 10.

[0022] Among the above components, the polypropylene resin is homopolypropylene, the compatibilizer is hydrogenated styrene-butadiene block copolymer, and the antioxidant is tetrakis [3-( 3,5-di-tert-butyl-4-hydroxypheny...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com