Automatic yarn separating device for spandex filaments

A spandex filament, automatic technology, applied in the field of spandex spinning, can solve problems such as unwinding, easy knotting, unevenness, etc., and achieve the effect of fast spinning speed, less operator operation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

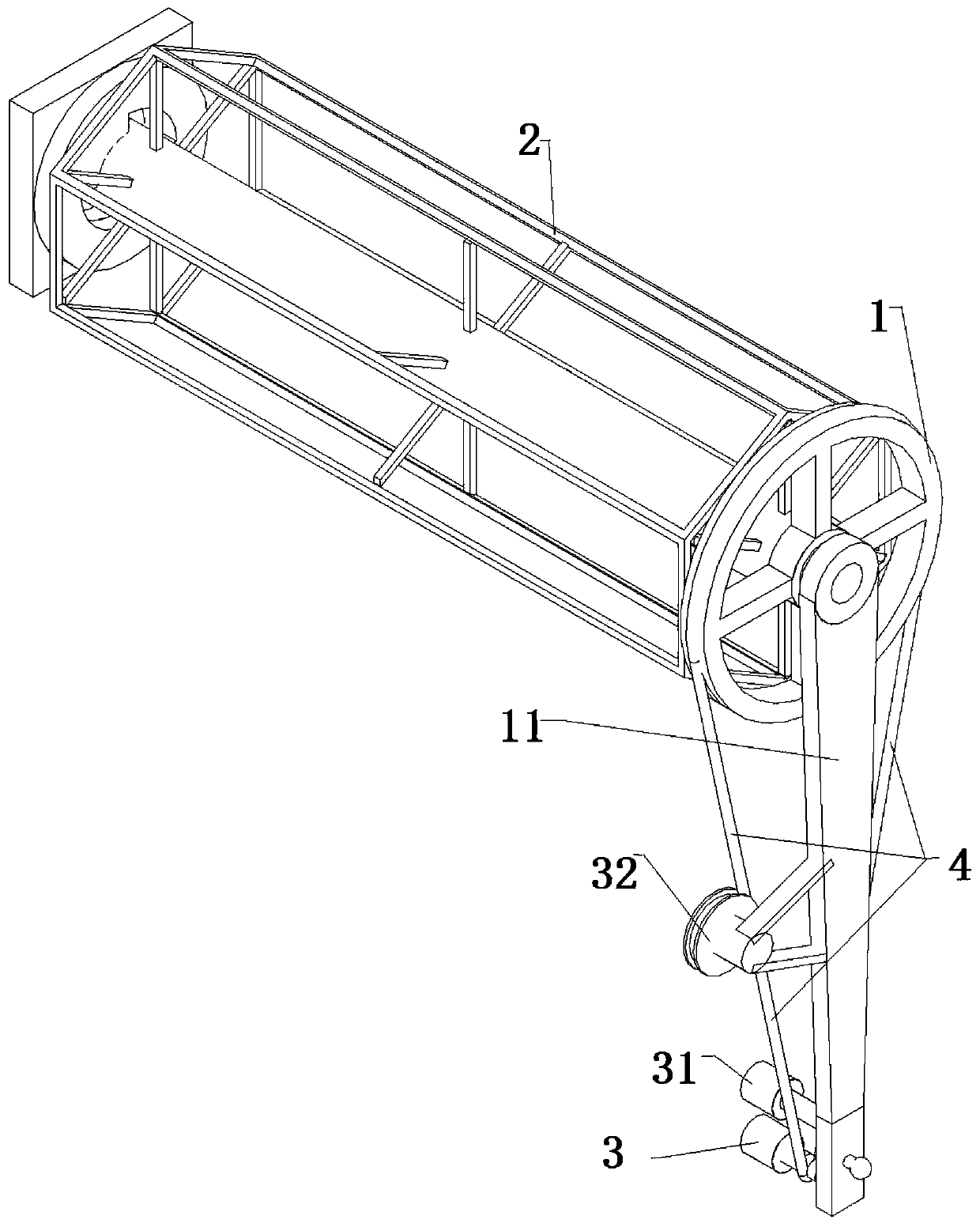

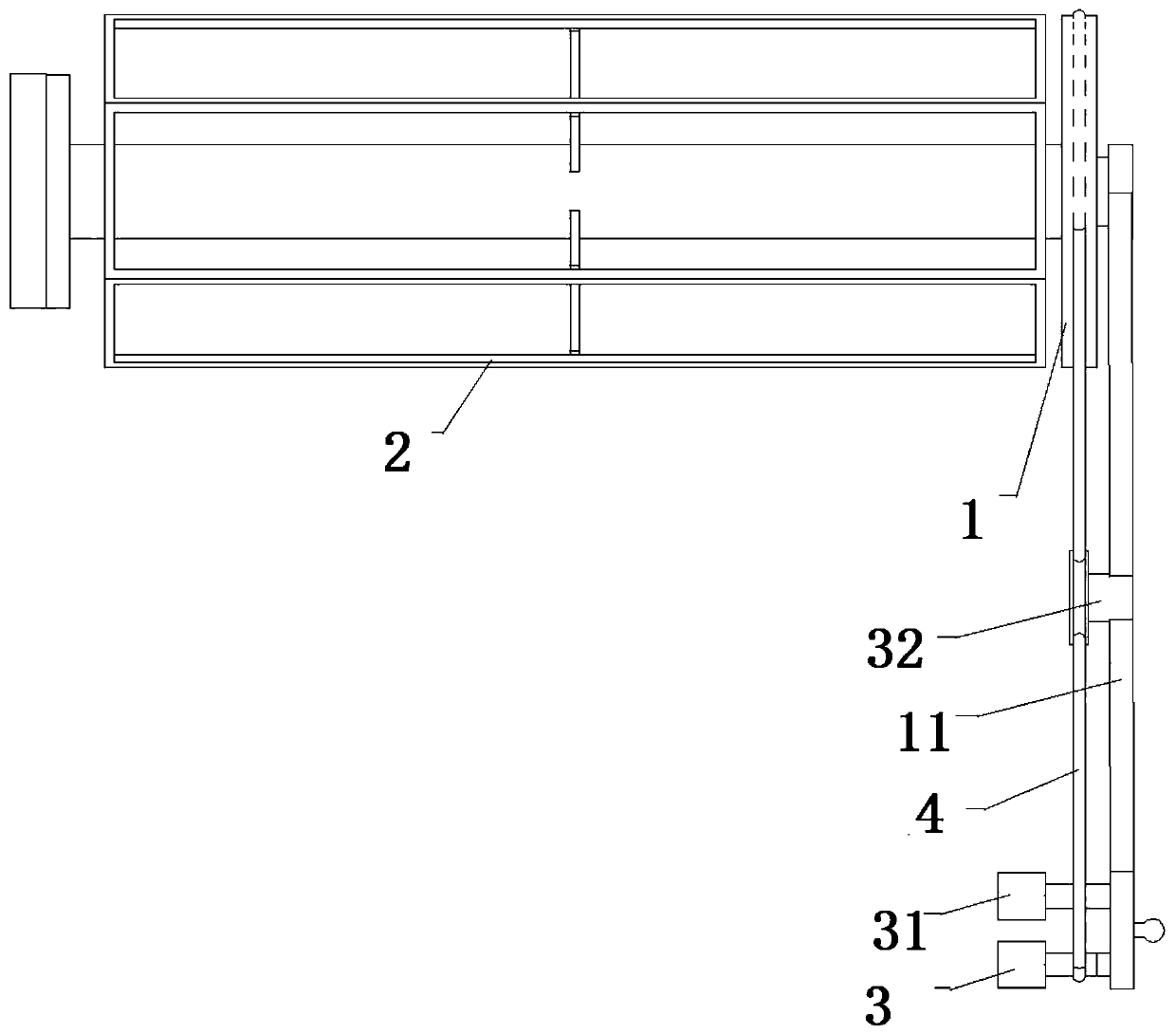

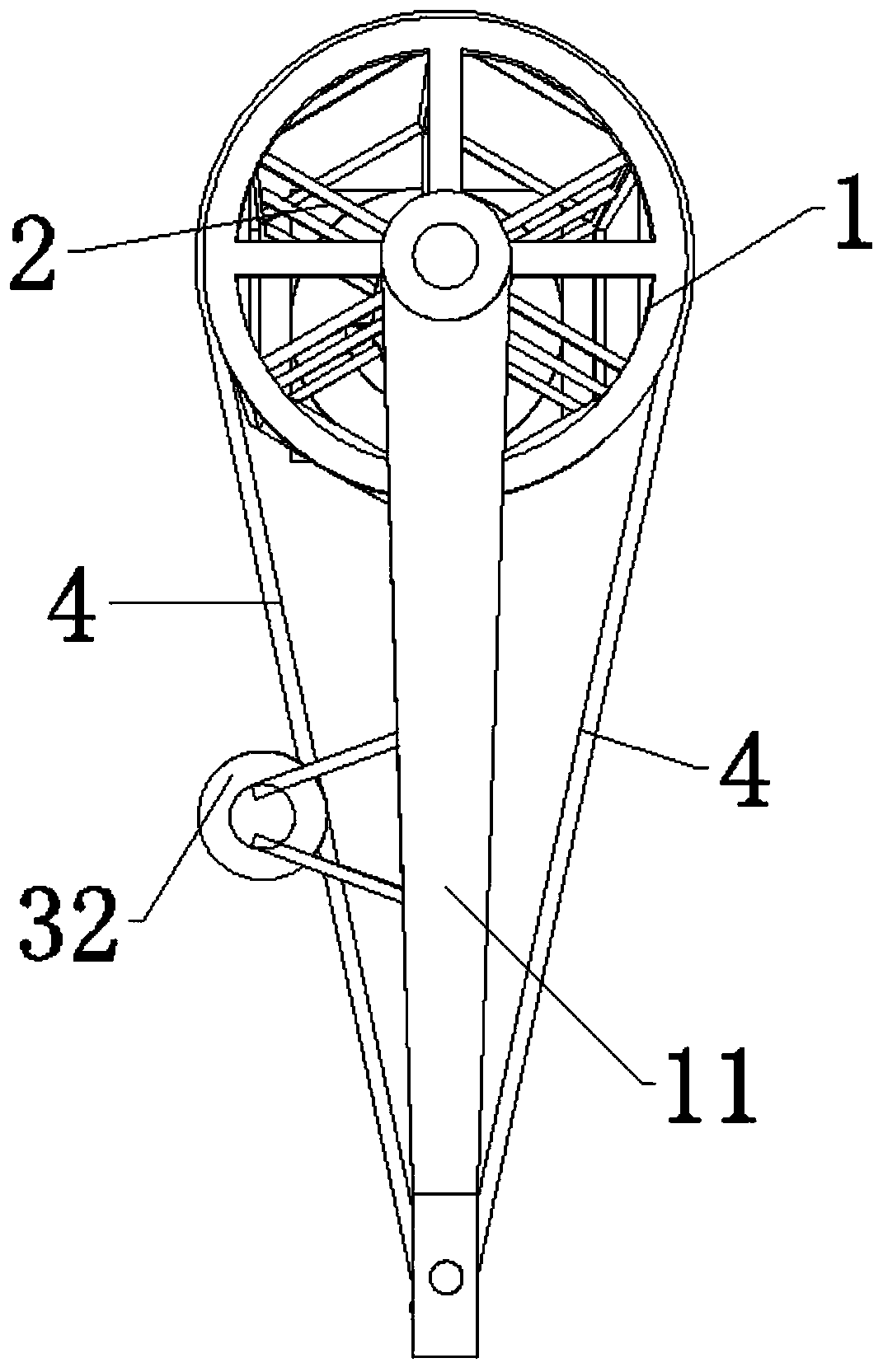

[0028] see Figures 1 to 4 As shown, the present invention provides a technical solution: an automatic spinning device for spandex filaments, comprising a driving wheel 3, the rotating shaft of which is fixed on the driving roller of the silk thread, and the driving wheel 3 passes through a transmission belt 4 with 1;

[0029] Driven wheel 1, described driven wheel 1 is connected with driving wheel 3 by transmission belt 4;

[0030] A splitting roller 2, the splitting roller 2 includes a rotating shaft 21 and a splitting frame 22, the splitting frame 22 is a regular polygonal tubular frame, and the splitting frame 22 is fixedly sleeved on the periphery of the rotating shaft 21;

[0031] The rotating shaft 21 of the spinning roller 2 is fixedly mounted on the driven wheel 1, and the axes of the rotating shaft 21, the splitting frame 22 and the driven wheel 1 are in the same straight line;

[0032] The linear speed of the said splitting roller 2 and driving wheel 3 is the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com