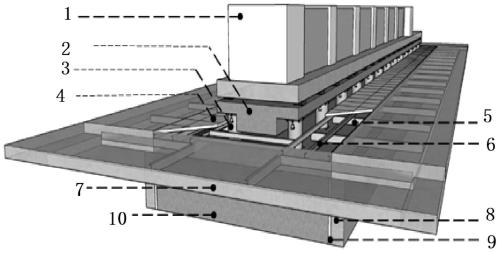

Open type sinking air floatation platform overhead floor overhanging vibration damping system

A raised floor and air-floating platform technology, which is applied to local raised floors, springs/shock absorbers, vibration suppression adjustment, etc. The effect of facilitating the organization of construction and reducing the difficulty of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Open-type submerged air-floating platform overhead floor cantilever vibration reduction system, the system is proposed for the air-floating workbench, the ultra-precision air-floating workbench system is the core subsystem of the current precision semiconductor manufacturing equipment, etc., requiring nano-level repeated positioning precision and synchronous motion precision. Due to the design of air bearings, etc., the system will experience vibrations with amplitudes of nanometers, which will affect the accuracy of the system. Micro vibrations are not the "air hammer" phenomenon that occurs in traditional air bearings. Micro vibrations occur in the bearing itself. in normal working condition. When microvibration occurs, its amplitude is usually several nanometers to tens of nanometers, and its frequency is from tens of hertz to several thousand hertz. A distinctive feature of this vibration, which occurs only when the air bearing is ventilated, is a fluid-induced vib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com