Test device for simulating tunnel active fault crossing

A technology of active faults and test devices, applied in measurement devices, geographic modeling, instruments, etc., can solve the problems of not considering the influence of the surrounding rock properties at the bottom of the tunnel, unable to simulate the reciprocating dislocation of the fault and the change of the movement rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

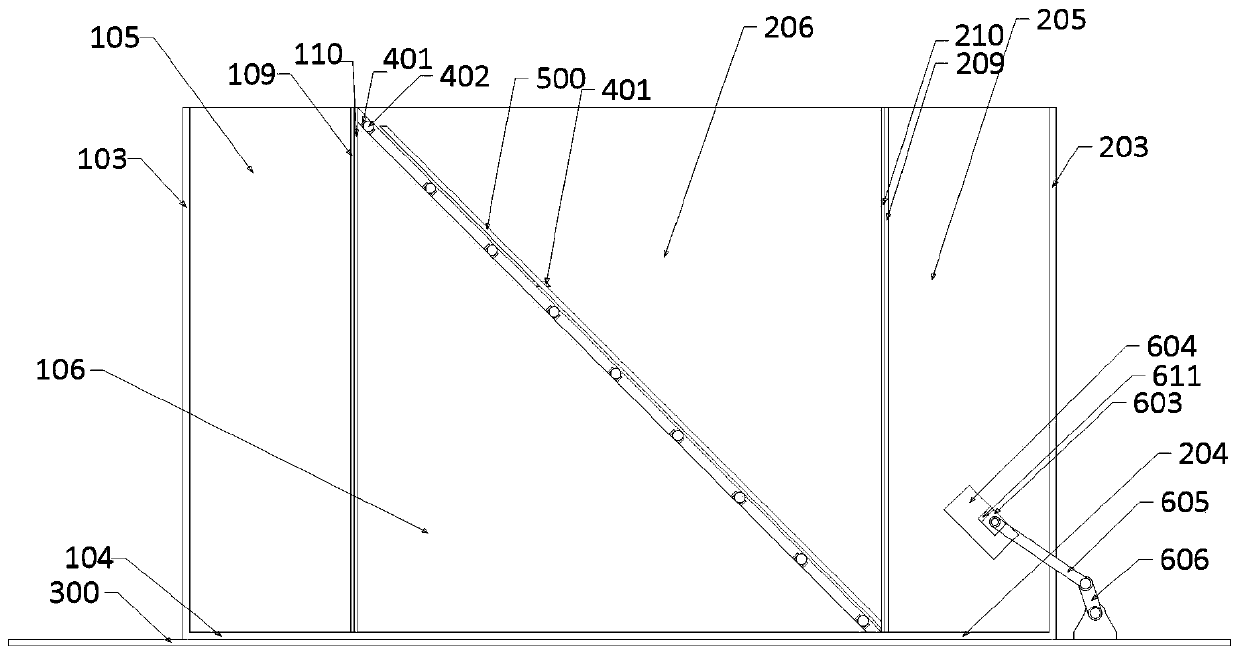

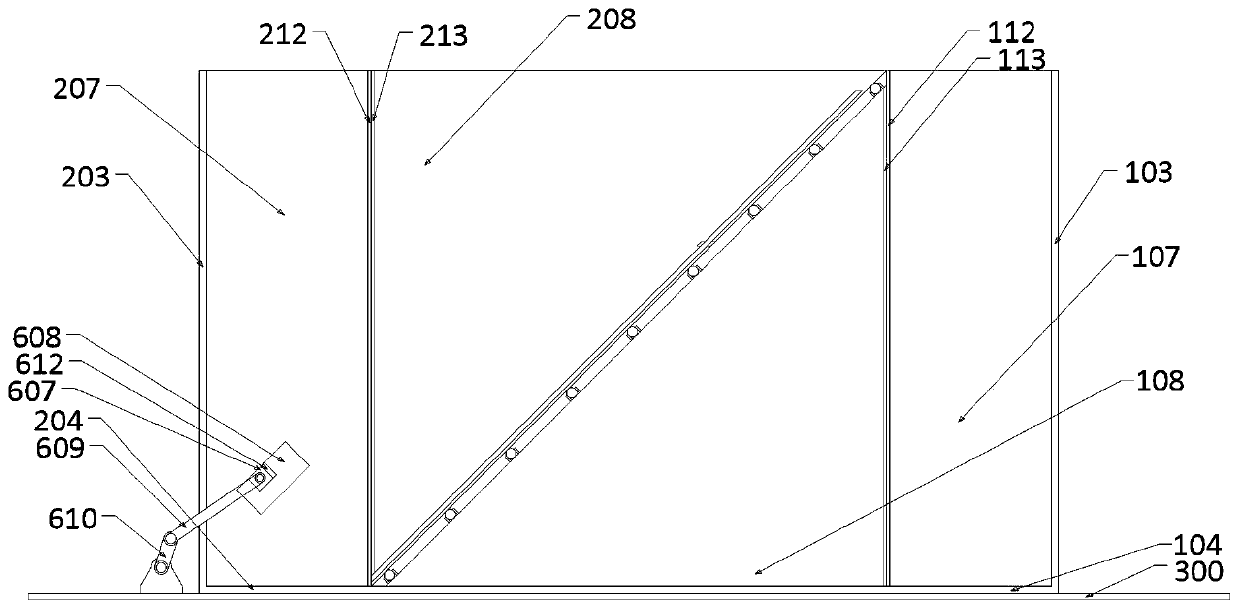

[0022] The test device for simulating a tunnel crossing an active fault includes: a fixed box 100 , a movable box 200 , a rigid base 300 , a roller support 400 , a movable steel plate 500 and a crank slider loading device 600 .

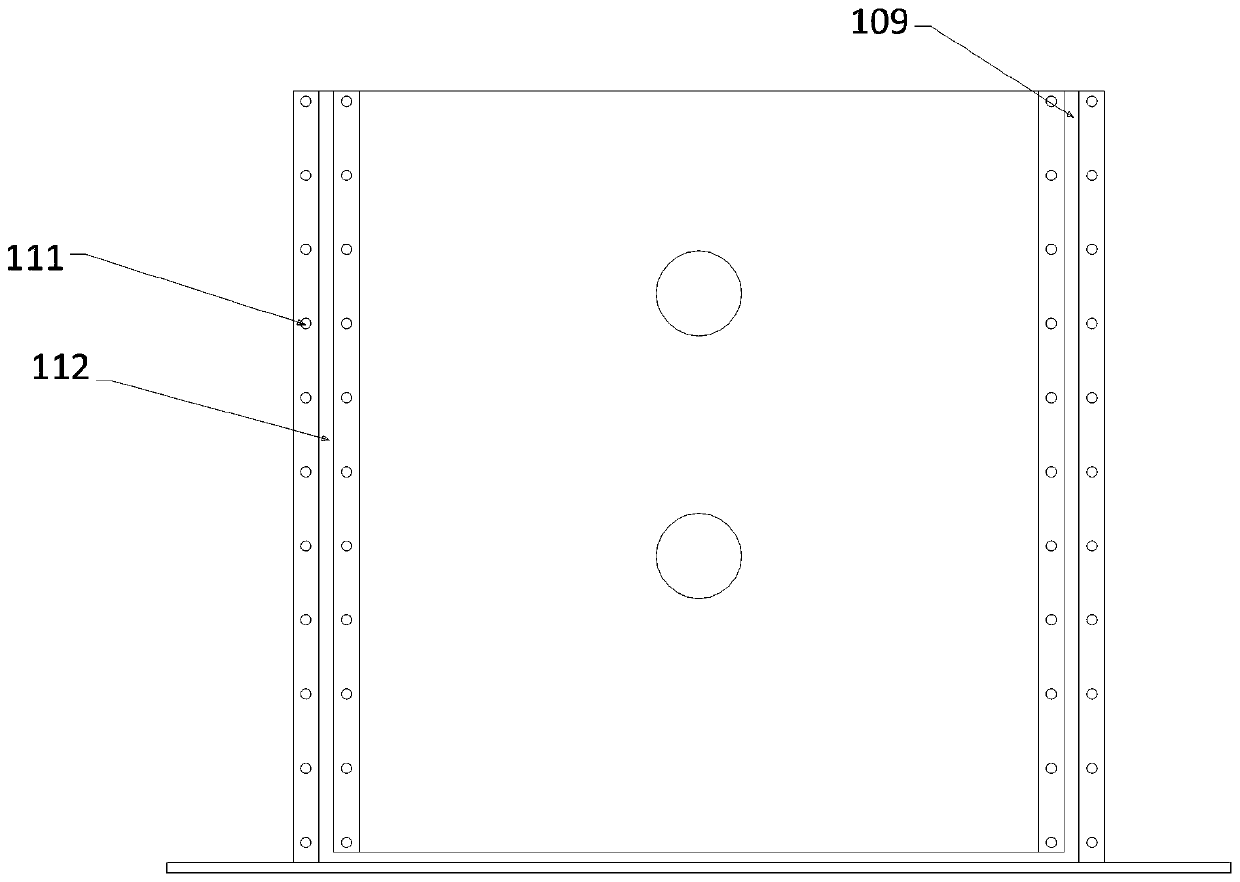

[0023] The fixed box 100 is composed of a left front plate 101 , a left rear plate 102 , a left side plate 103 , a left bottom plate 104 , and a roller support 400 . The left front plate 101 is composed of a left front rectangular steel plate 105 and a left front triangular steel plate 106. The left front rectangular steel plate 105, the right T-shaped steel plate 109 and the left front triangular steel plate 106, the left T-shaped steel plate 110 are connected by high-strength bolts 111; Rectangular steel plate 107 and left rear triangular steel plate 108 constitute, left rear rectangular steel plate 107 right T-shaped steel plate 112 and left rear triangular steel plate 108 left T-shaped steel plate 113 are connected by high-strength bolts 111; left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com