H-bridge drive circuit and current sensor based on H-bridge drive circuit

A bridge drive circuit and current sensor technology, applied in the field of sensing, can solve problems such as inapplicability, increased coil size, and large space, and achieve the effects of improving functional safety, large-range measurement, and high-precision measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

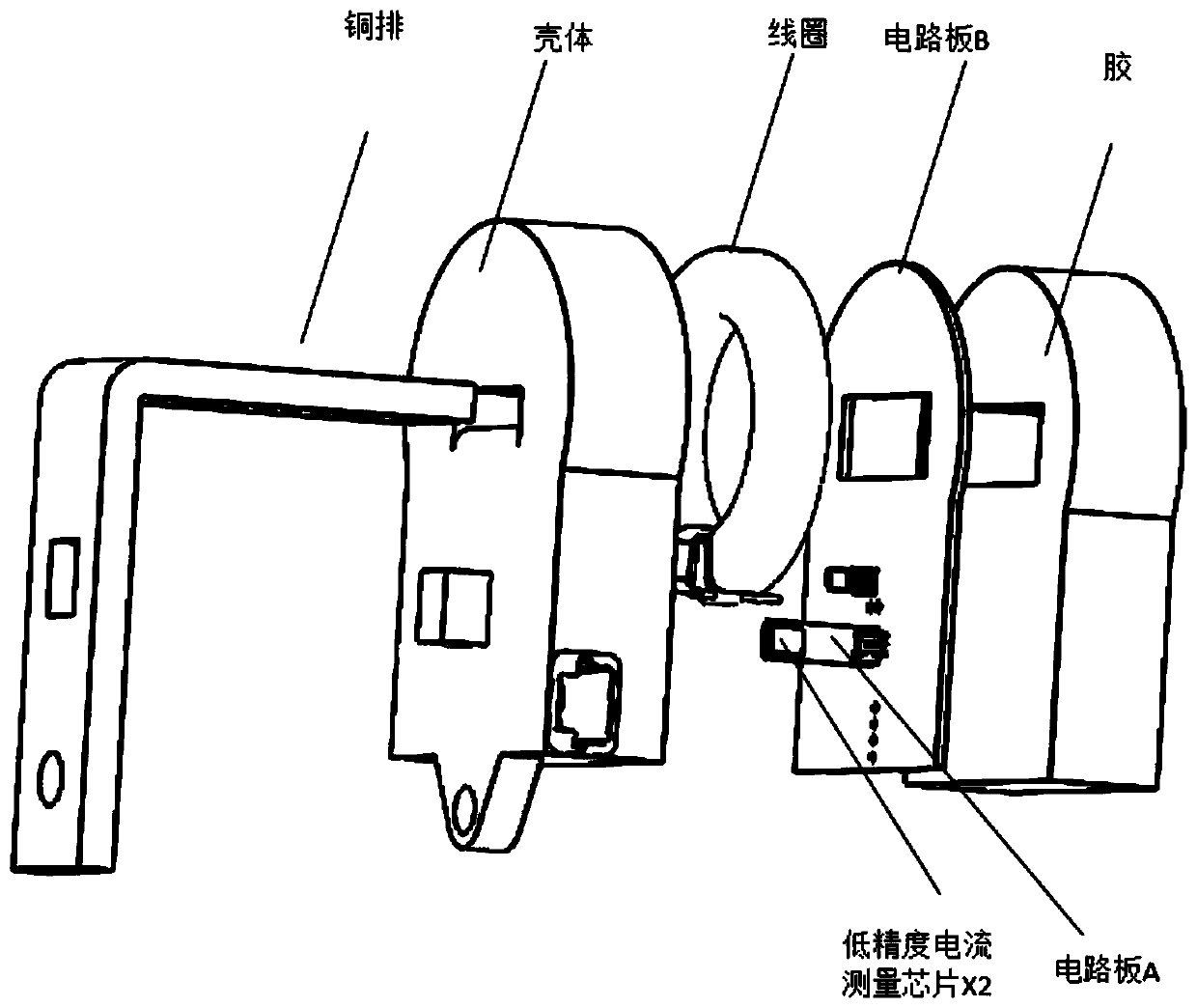

[0034] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

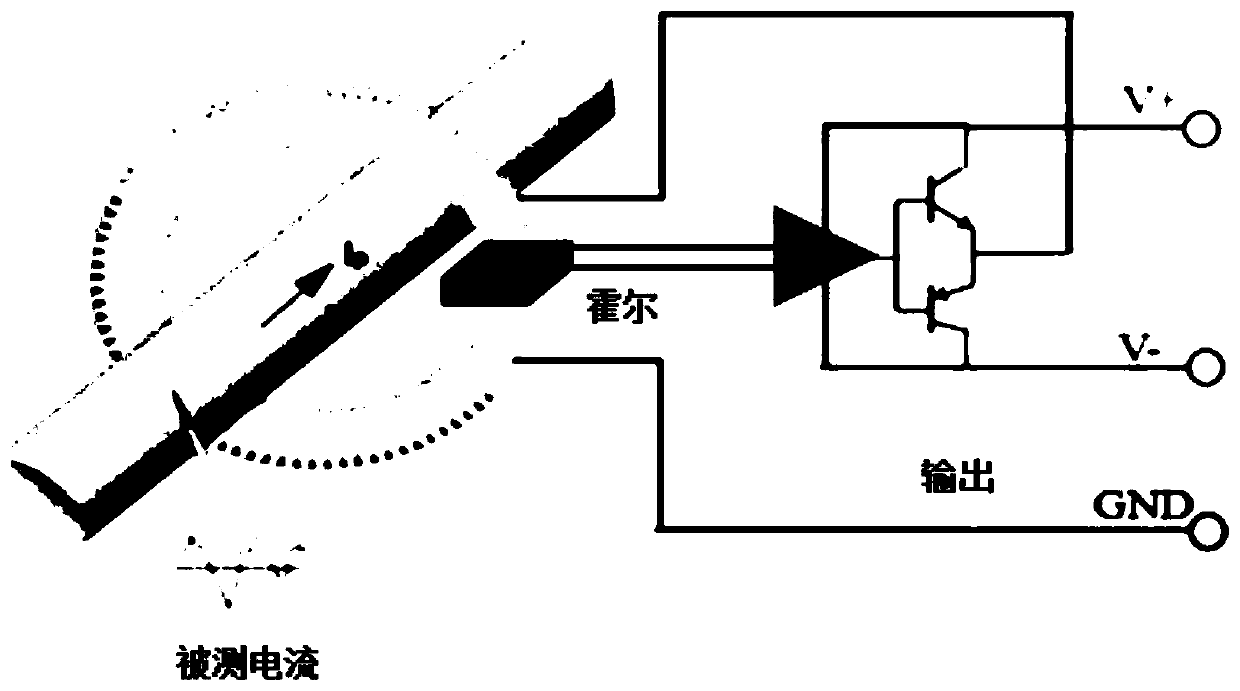

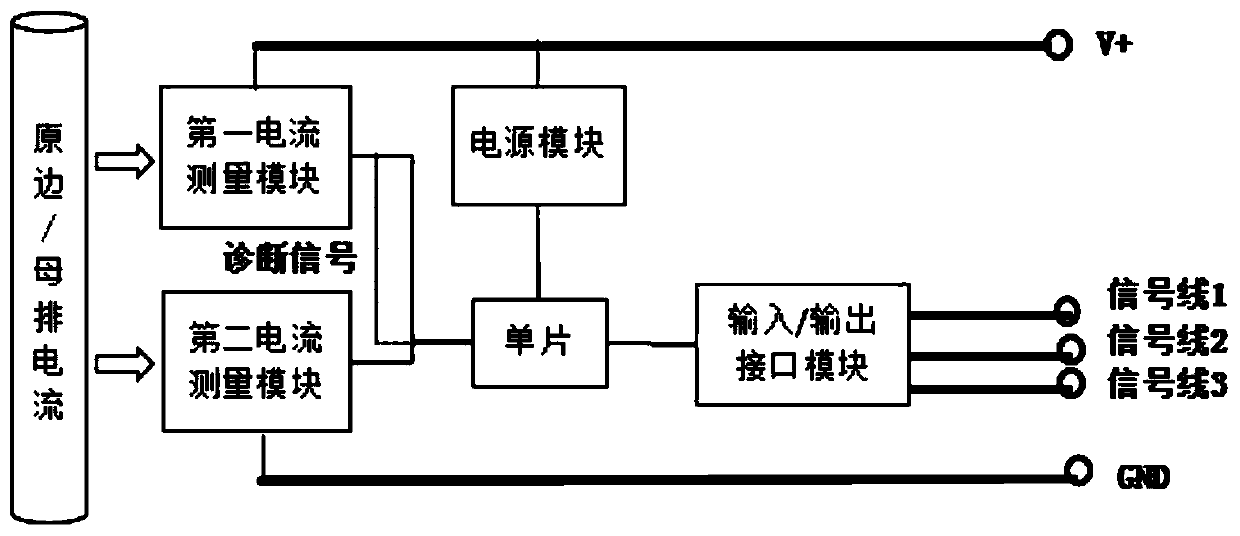

[0035] The present invention proposes an H-bridge driving circuit, comprising a first operational amplifier OP1, a second operational amplifier OP2, N first NPN transistors T1, N first PNP transistors T2, N second NPN transistors T3, N first Two PNP transistors T4, first to second resistors R1-R2 and sampling resistor Rs, N≥1; where,

[0036] The input terminal of the first operational amplifier OP1 is connected with the output terminal of the external magnetic sensitive unit, the output terminal of the first operational amplifier OP1 is connected with the base pole of the first NPN transistor T1 and the base pole of the first PNP transistor T2 respectively, the first The collector of the NPN transistor T1 is connected to the collector of the second NPN transistor T3, the emitter of the first NPN transistor T1 is connected to the emitter of the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com