A fully automatic noodle machine

A noodle machine, fully automatic technology, applied in the directions of dough extruder, horizontal installation tool mixing/kneading, etc., can solve problems such as inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

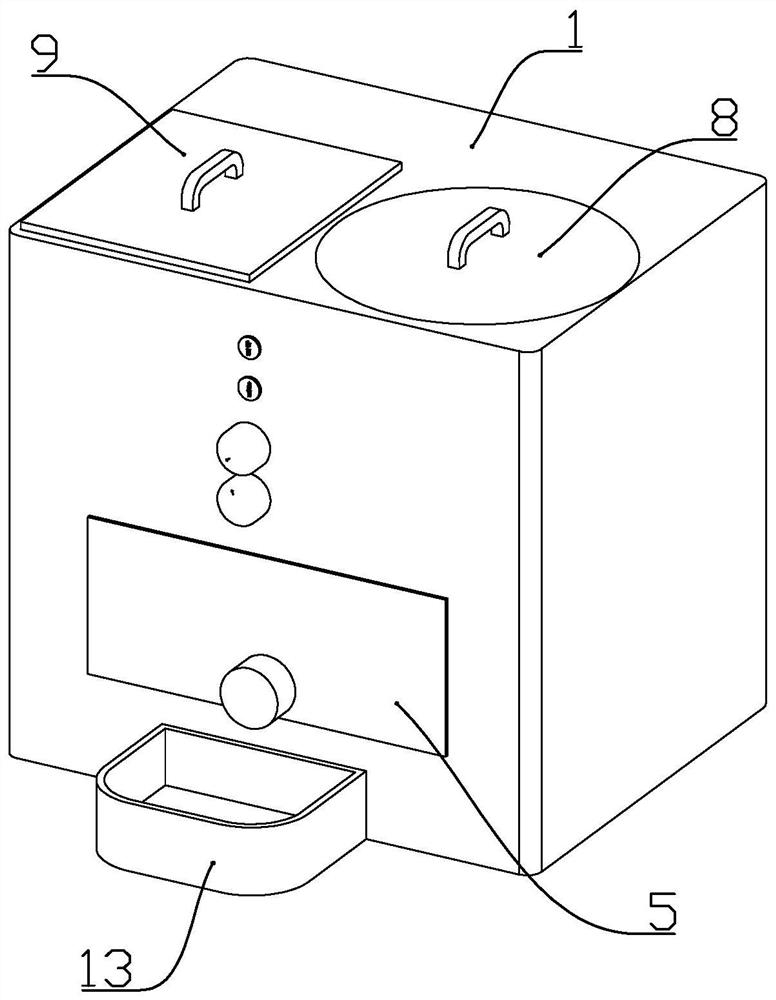

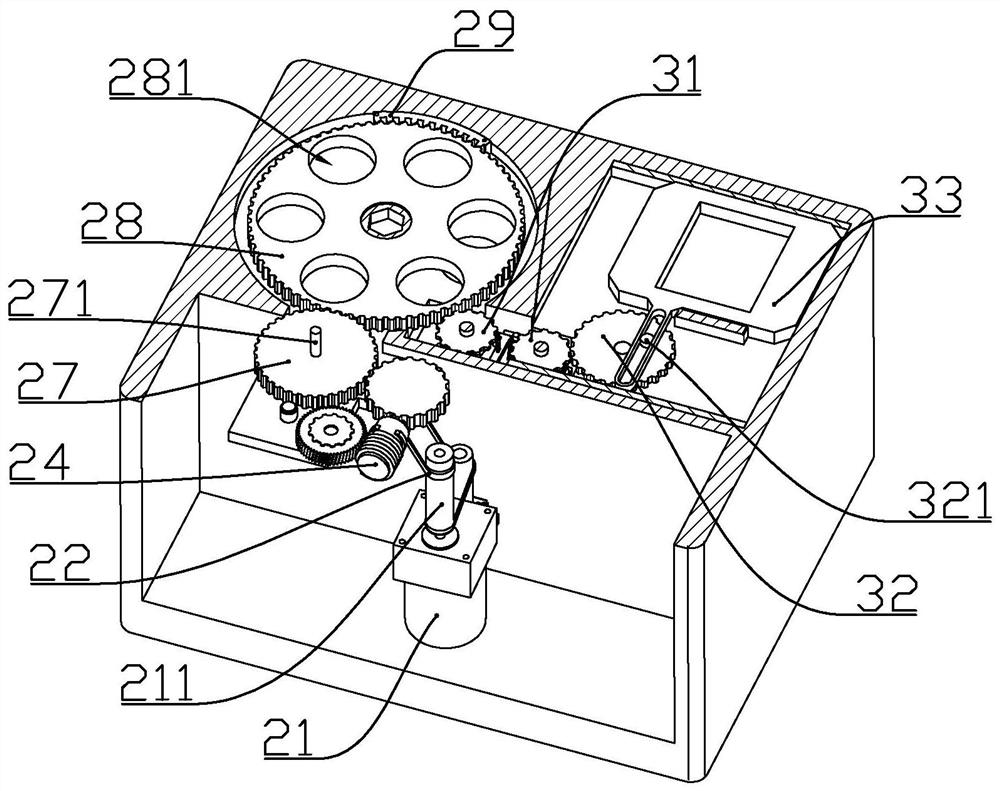

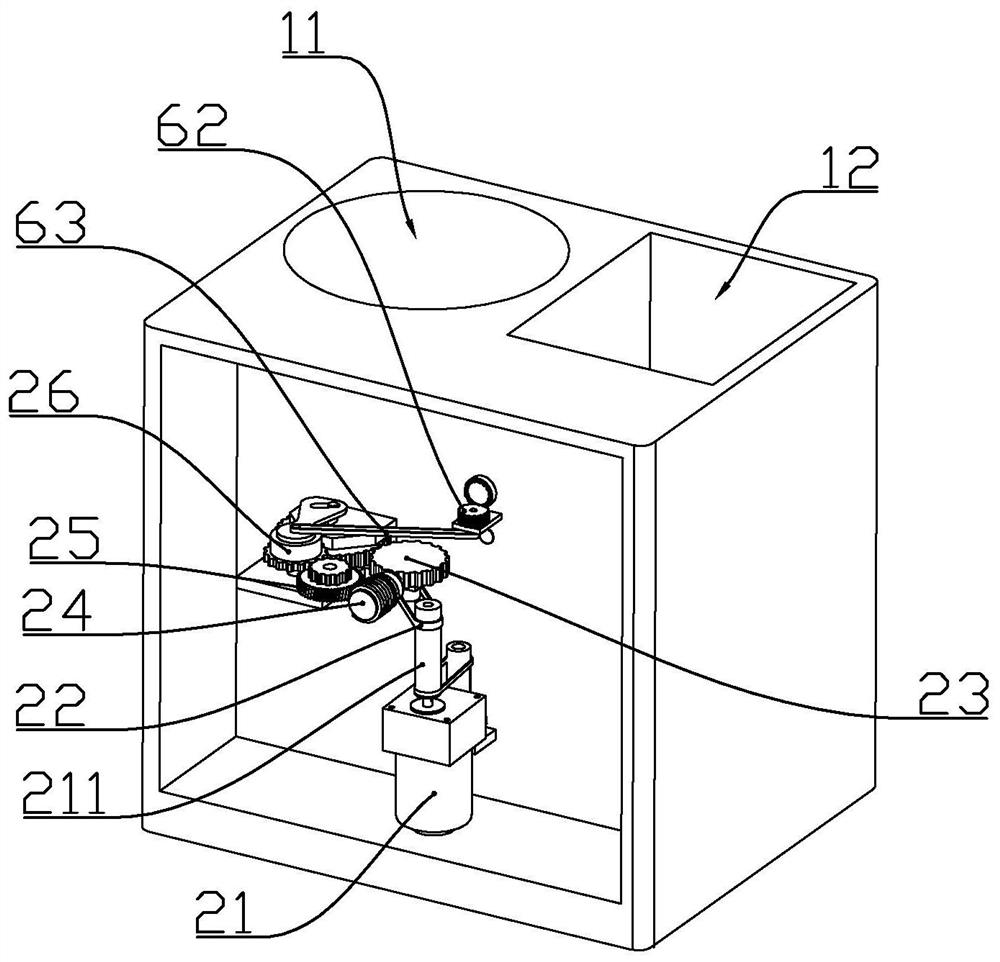

[0048] according to Figure 1 to Figure 19 As shown, a fully automatic noodle machine in this embodiment includes a housing 1; a temporary flour storage chamber 11 and a water tank 12 are formed on the upper end of the housing 1; Cover 8; the top of the water tank 12 is detachably installed with a water tank cover 9; the bottom of the flour temporary storage chamber 11 is equipped with a flour blanking assembly for controlling flour blanking; the bottom of the water tank 12 is equipped with a The water outlet assembly; the lower part of the housing 1 is detachably connected with a mixing base 5 for receiving the flour falling from the flour temporary storage chamber and the water falling from the water tank; noodle assembly; the noodle machine also includes a servo motor 21 for driving the flour feeding assembly, controlling the water outlet group and working with the noodle assembly.

[0049] The flour feeding assembly includes a delivery gear 28 driven by the servo motor 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com