Rotary chopping board, manufacturing method and combined knife matched with rotary chopping board

A cutting board and rotating device technology, applied in the field of kitchen supplies, can solve the problems of uneven meat chopping, time wasting, and efficiency reduction, and achieve the effects of improving efficiency, reducing centrifugation problems, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

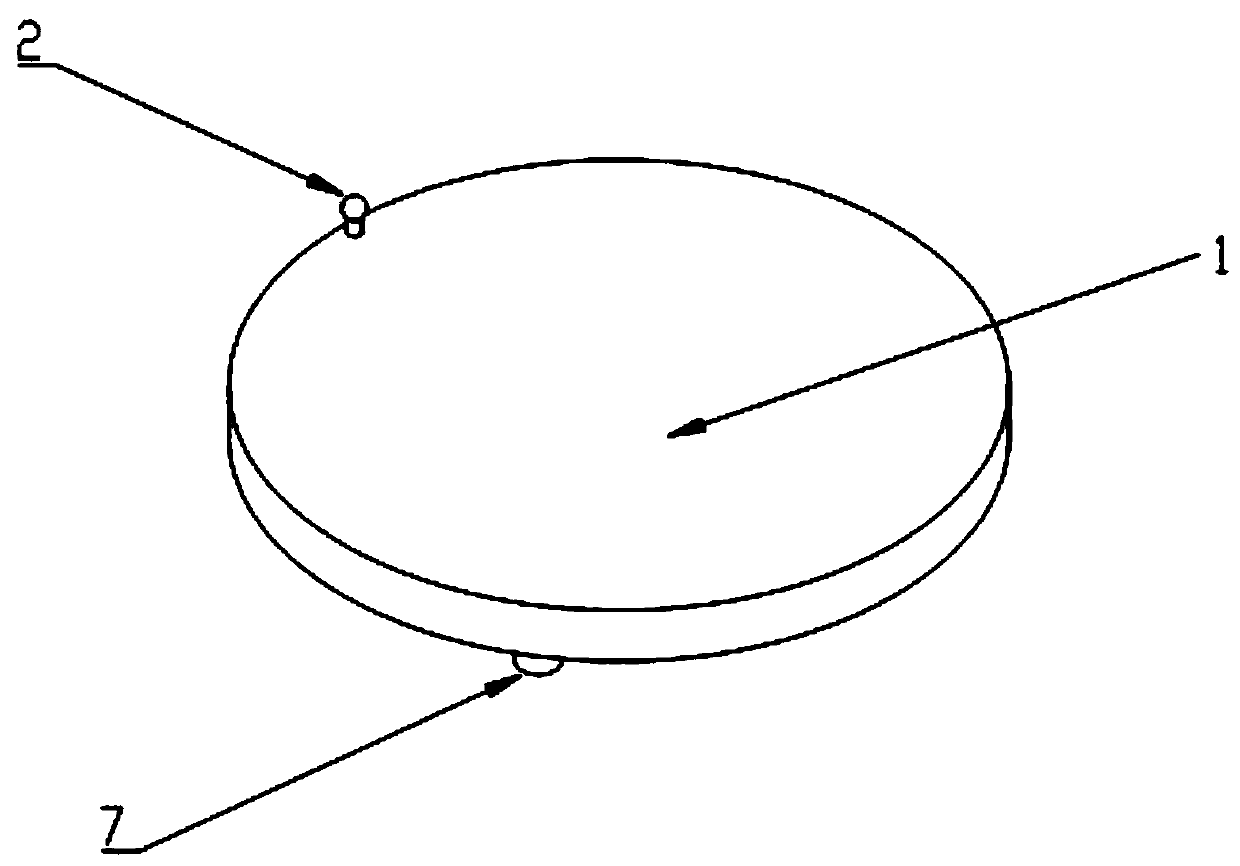

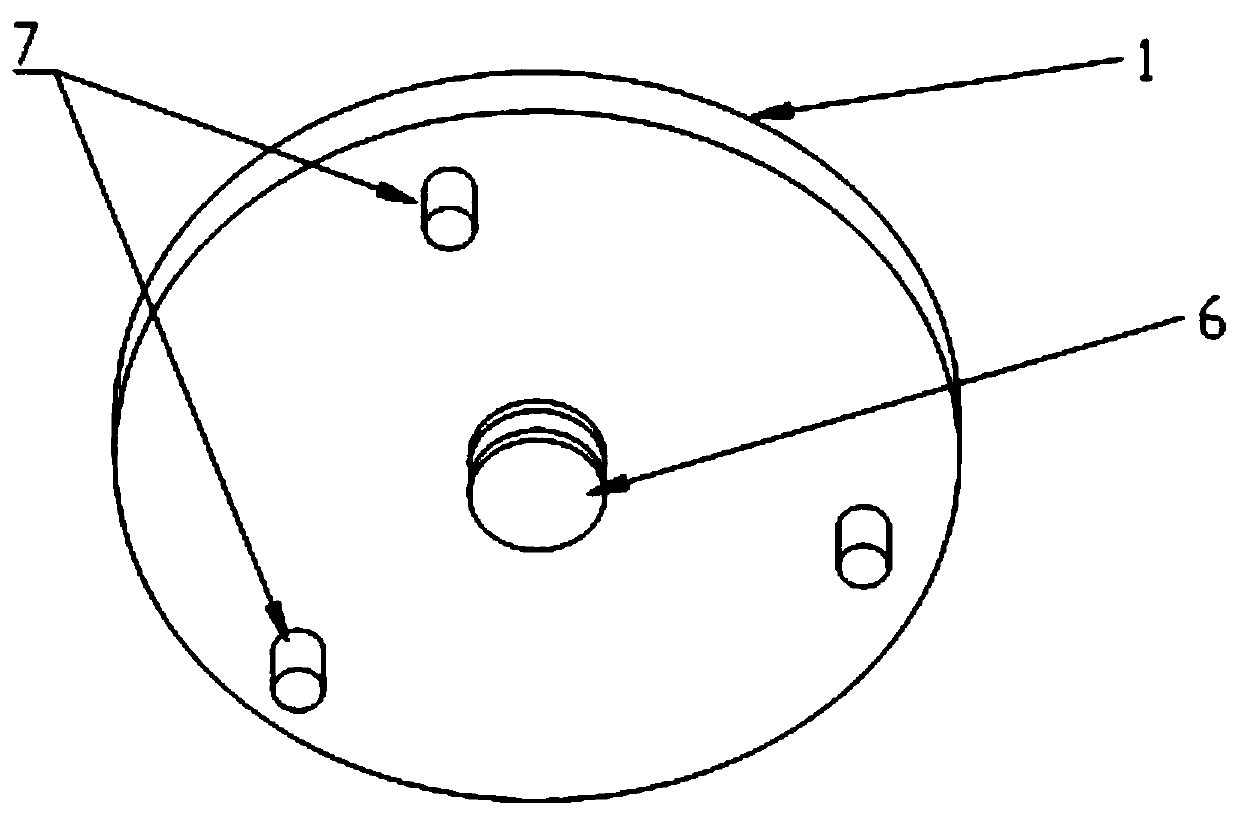

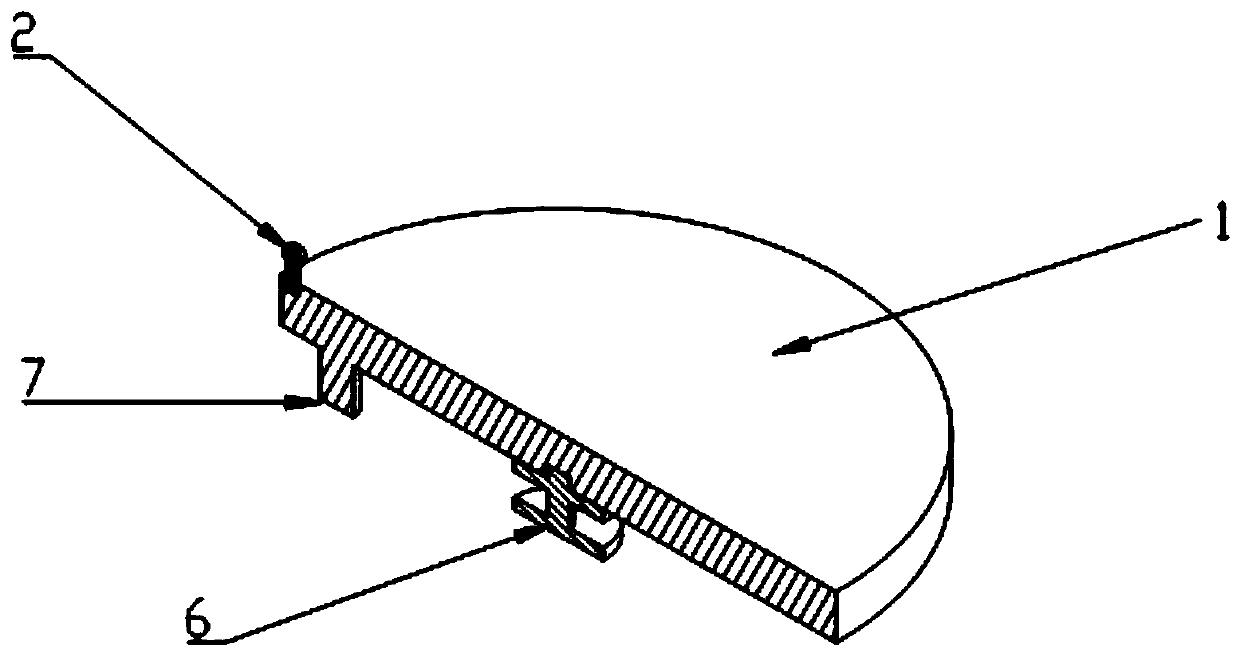

[0061] Such as Figure 1 to Figure 5As shown, the rotary cutting board and the manufacturing method of the present invention include a cutting board 1, which can be a square or circular cutting board, and the cutting board 1 can be selected as a common cutting board; The adjustment part 2 fixedly connected with the cutting board 1, the steps are: first drill a concave second connection hole 4 at the position near the side above the cutting board 1, and the second connection hole 4 can also be made in other ways; A protruding adjusting part 2 is installed in the second connection hole 4, so that the adjusting part 2 is fixedly connected with the cutting board 1 through the second connecting hole 4, and the adjusting part 2 is made of a material with a smooth surface. If it is a material with a rough surface, the adjusting part 2. The connection with the cutting board 1 is set as a flexible connection, which is used to reduce the friction force of the hand during use; at the sam...

Embodiment 2

[0066] Depend on Figure 6 to Figure 11 As shown, the rotary cutting board and the manufacturing method of the present invention, on the basis of the cutting board 1 and the adjusting member 2 of Embodiment 1, change the first connecting hole 3 below the cutting board 1 into an outwardly protruding connecting member 9 (the connecting member 9 can be an integral structure with the cutting board 1, or it can be a separate part installed inside the first connecting hole 3 in the structure of Embodiment 1), and at the same time, the rotating device 6 and the support member 7 of Embodiment 1 are replaced by Bottom plate 10, the size of the bottom plate 10 can be larger than the cutting board 1 or smaller than the cutting board 1, and can also be equal to the size of the cutting board 1, at the center above the bottom plate 10, and at the same time it is a position corresponding to the connecting piece 9 below the cutting board 1, A sunken third connecting hole 5 is drilled, and the...

Embodiment 3

[0070] Depend on Figure 12 to Figure 18 As shown, the rotating chopping board and the manufacturing method of the present invention, on the basis of Embodiment 1, replace the rotating device 6 under the cutting board 1 with a separate rotating base 13, which is a rotating bearing, or with the rotating bearing Other components with the same function make the rotating base 13 support the cutting board 1, and at the same time make the cutting board 1 have a rotating function, and then add a connecting piece 9 on the basis of embodiment 1, and the connecting piece 9 is installed in the first connecting hole 3, Pass through the center of rotating base 13 vertically at the same time, cooperate with rotating base 13 gaps; Install a chassis 14 that is fixedly connected or screwed with connector 9 below rotating base 13 in addition, make cutting board 1 and rotating base 13 and chassis 14 rely on The connecting piece 9 is connected as a whole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com