Device for cleaning sediments in machine tool water tank

A machine tool water tank and sediment technology, applied in the direction of cleaning hollow objects, cleaning methods and utensils, metal processing mechanical parts, etc., can solve the problems of occupying machine tool processing time, low cleaning efficiency, time-consuming and laborious, etc., to reduce enterprise losses and save time. , the effect of avoiding machine downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

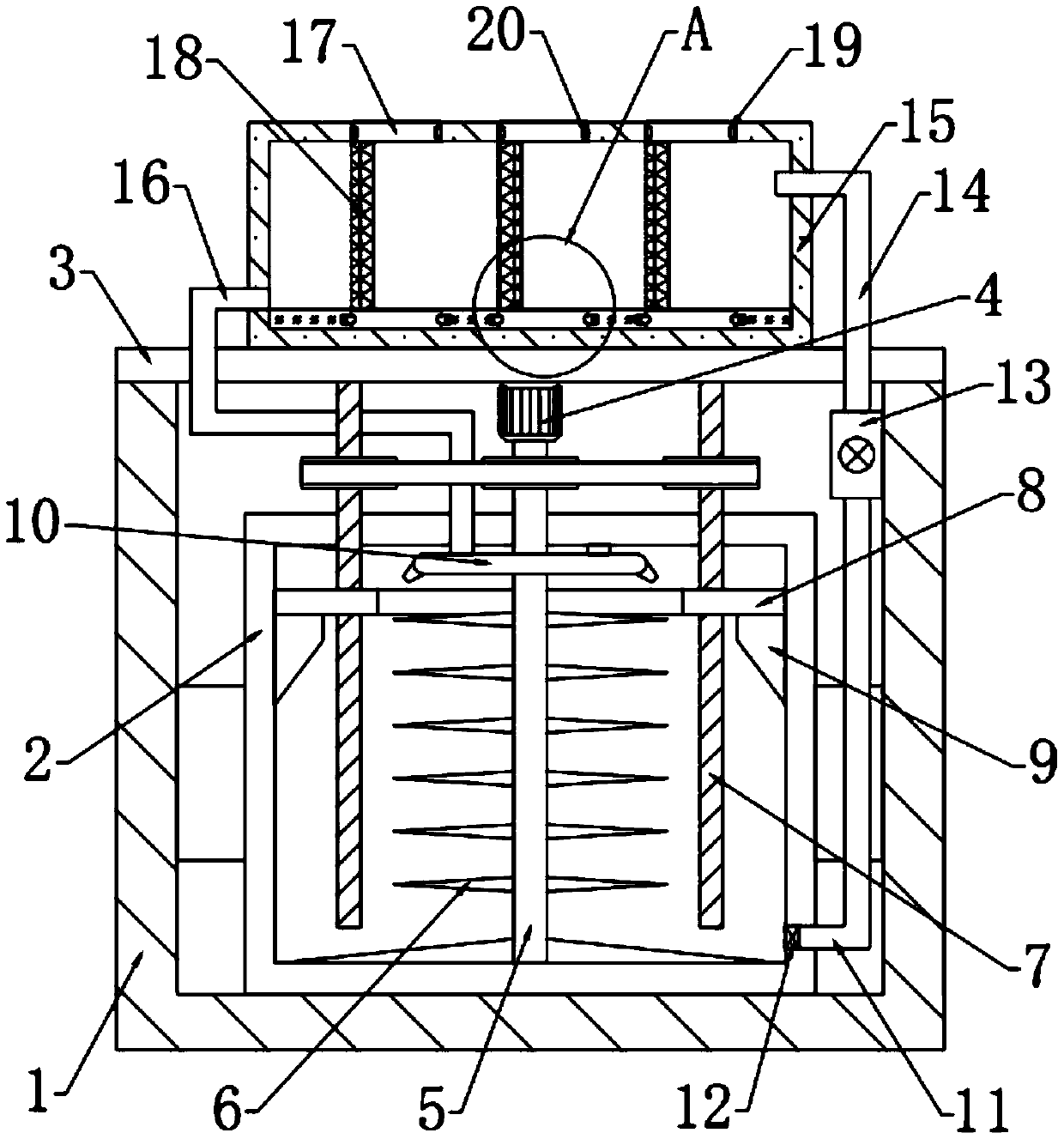

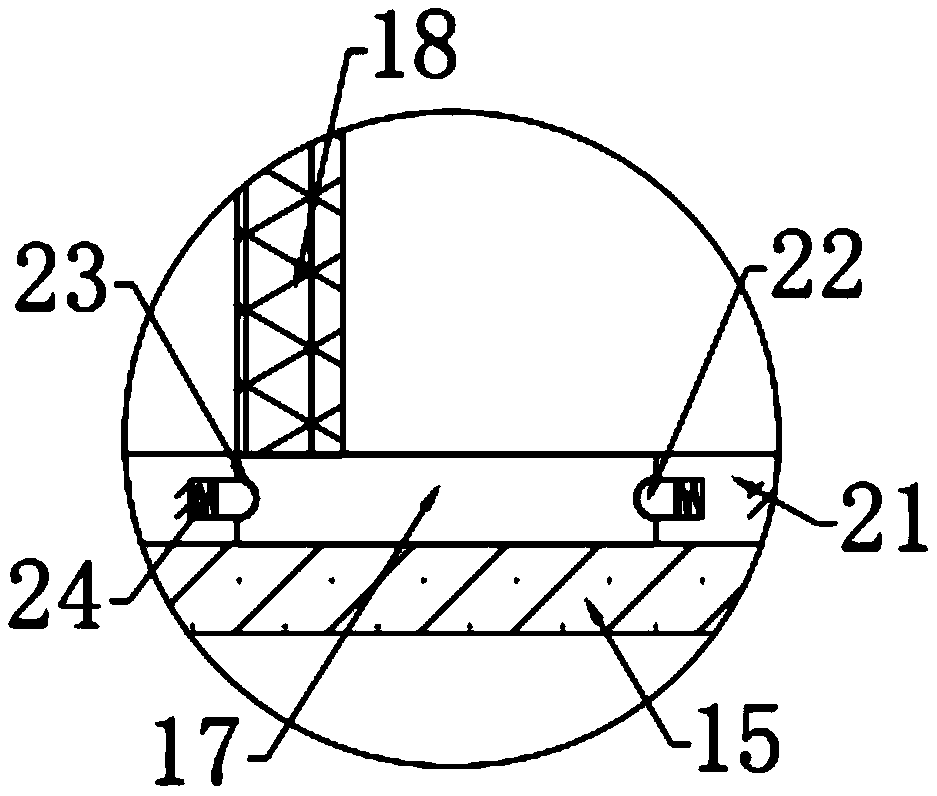

[0025] see Figure 1-3 , in an embodiment of the present invention, a device for cleaning machine tool water tank sediments includes a support frame 1, a water tank 2 is fixedly connected to the inner side of the support frame 1, and a chip removal mechanism is arranged on the inner side of the water tank 2. A top plate 3 fixedly connected to the support frame 1 is provided on the side, and a purification mechanism for collecting sediment is provided on the top of the top plate 3 .

Embodiment 2

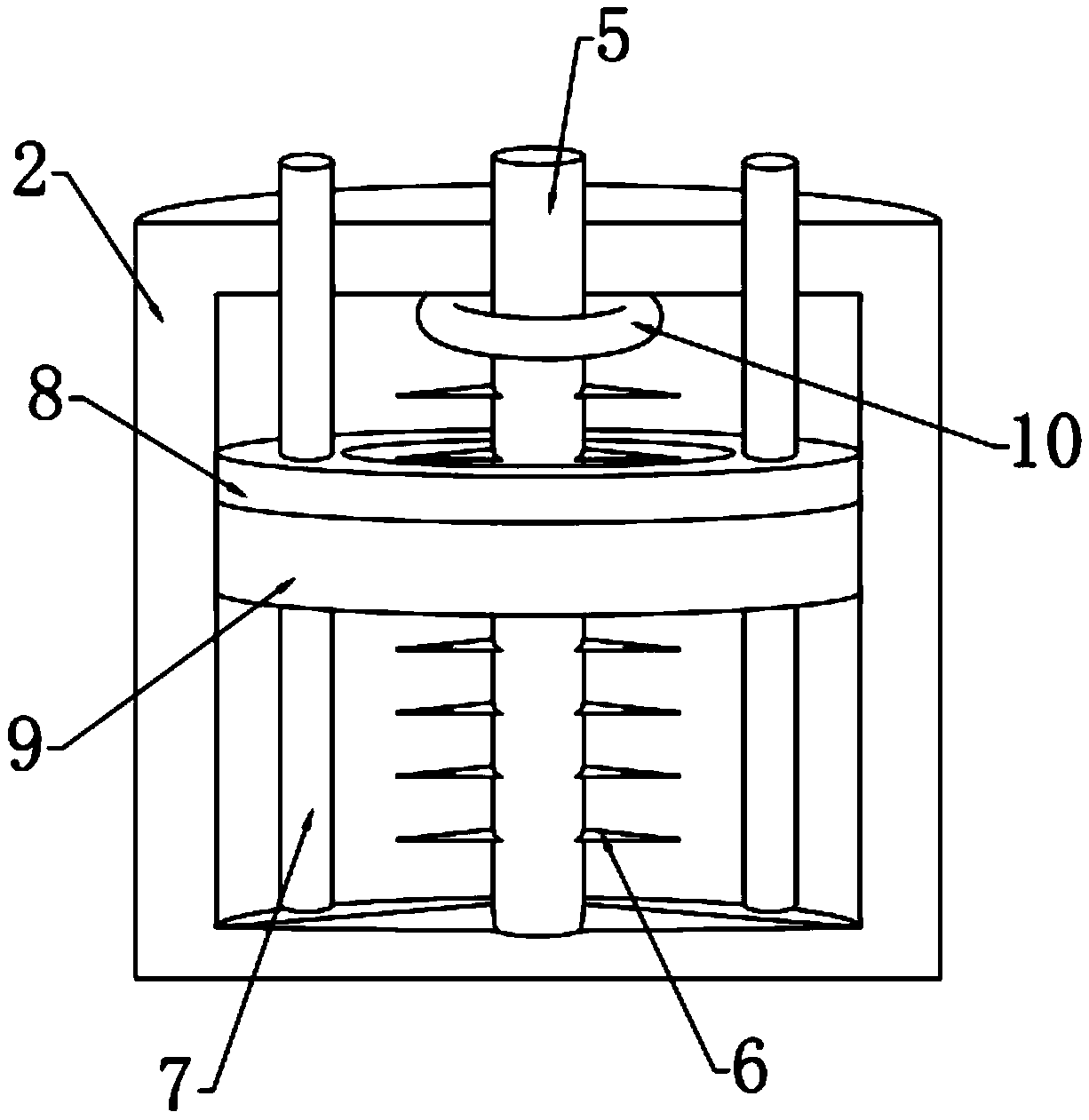

[0027] In this embodiment, the chip removal mechanism includes a push plate 8 arranged inside the water tank 2, and the bottom of the push plate 8 is fixedly connected with a scraper 9 that is attached to the inner side of the water tank 2. The left and right sides of the push plate 8 The inner sides of both ends are threadedly connected with a threaded rod 7, which is connected to the driving mechanism arranged at the bottom of the top plate 3. By setting the scraper 9 and moving up and down the scraper 9, the scraper attached to the box wall can be removed. The sediment is scraped off to facilitate the collection of the sediment.

[0028] In this embodiment, the drive mechanism includes a motor 4 bolted to the bottom of the top plate 3, the output end of the motor 4 is connected to the rotating rod 5, and the outer sides of the rotating rod 5 and the threaded rod 7 are fixedly connected with pulleys. , the pulleys are connected by a belt, and the bottom of the rotating rod 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com