Ultrasonic vibration assisted self-rotating grinding machine and main shaft device thereof

An ultrasonic vibration and machine tool spindle technology, applied in the field of grinding processing, can solve problems such as the development of limited ultrasonic-assisted self-rotating grinding machine tools, and achieve the effects of improving the quality of the machined surface, preventing the grinding wheel from clogging, and improving the grinding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

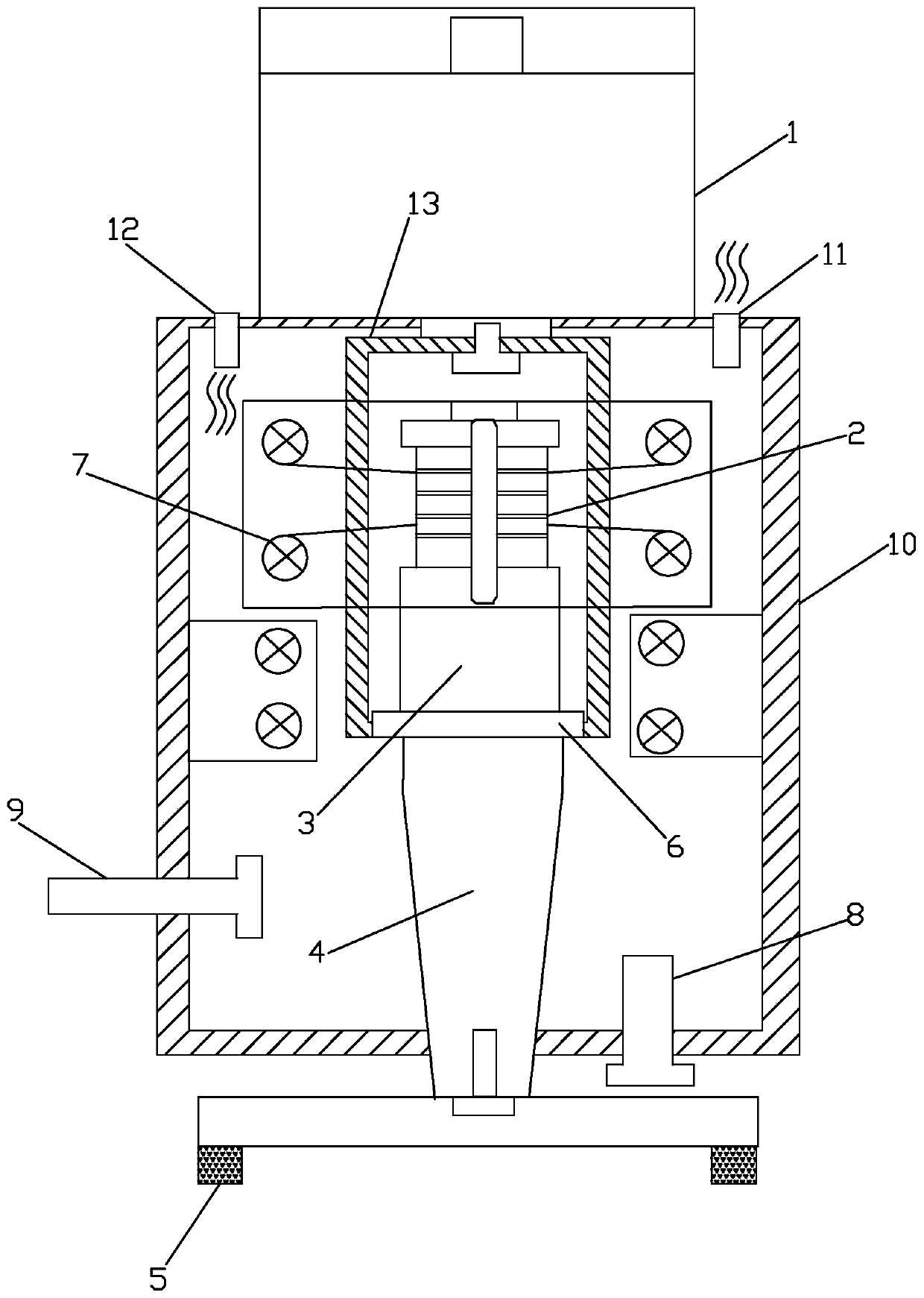

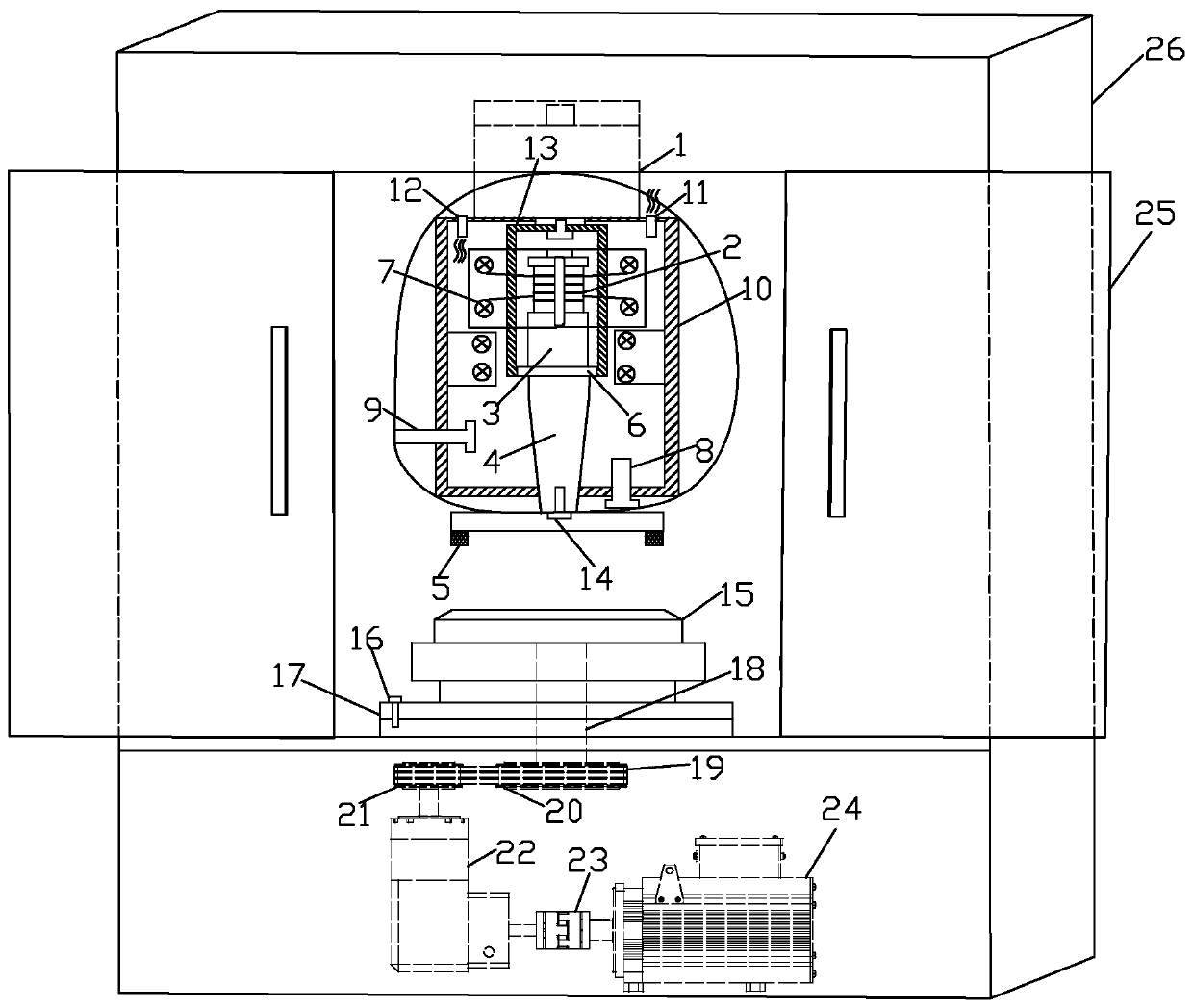

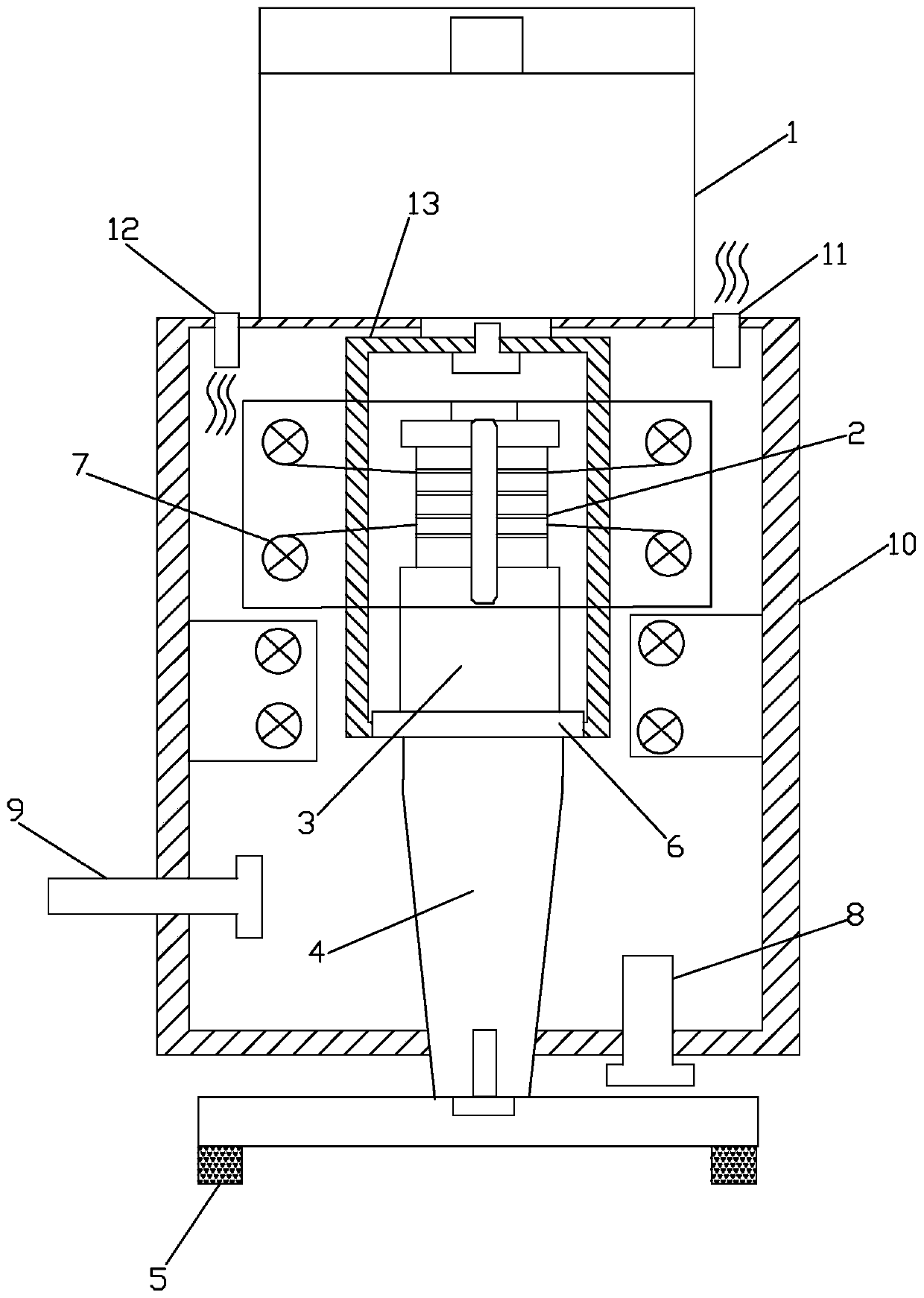

[0021] Please check figure 1 and figure 2 , the ultrasonic vibration assisted self-rotating grinding machine tool, including the machine tool main body and the main shaft device of the self-rotating grinding machine tool, the machine tool main body includes the machine tool shell part and the self-rotating part of the loading plate, and the main shaft device includes the rotating main shaft part and the ultrasonic vibration part , the ultrasonic vibration part is fixed on the rotating main shaft part.

[0022] The machine tool shell part includes a vertical box-shaped main shell 26 and a machine tool cabin door 25 mounted on the vertical box-shaped main shell 26 . The specific structure is as follows: the vertical box-shaped main casing 26 is provided with an opening, and the machine tool cabin door 25 is slidably or rotatably connected to the vertical box-shaped main casing 26 to open or close the opening.

[0023] The self-rotating part of the loading plate includes a loa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com