An Embedded Rail Transit System Applied to Mine

A rail transit and transportation system technology, applied in the field of transportation, can solve problems such as prolonging the transportation time, prolonging the coal mine hauling time, wheel jamming, etc., to achieve the effect of ensuring smooth operation and improving the quality of coal mine transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

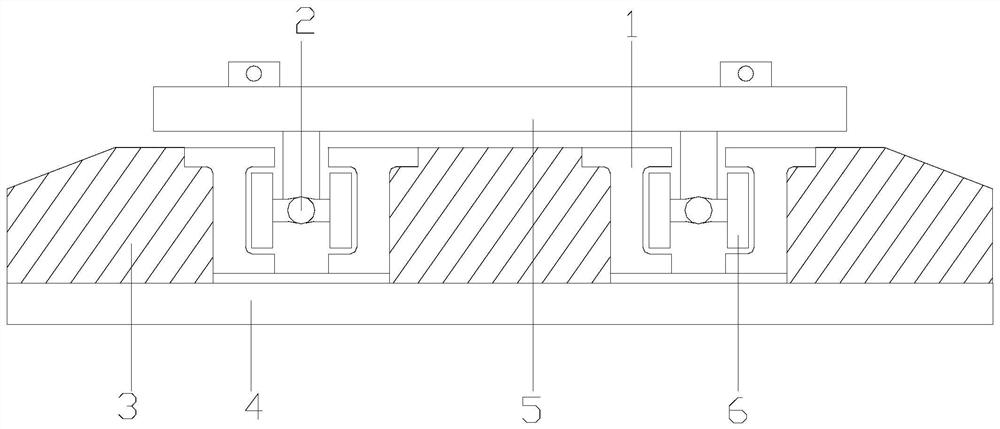

[0027] see Figure 1-Figure 5, the present invention provides an embedded rail transportation system applied to mines, the structure of which includes an embedded rail 1, a traction wheel connecting frame 2, a prestressed concrete slab 3, an adjustment layer 4, a carrier fixing structure 5, and a traction wheel The main body 6, the adjustment layer 4 is installed horizontally on the ground, the prestressed concrete slab 3 is located above the adjustment layer 4 and the bottom surface is attached to the upper surface of the adjustment layer 4, and the embedded track 1 is nested in the prestressed concrete slab 3 at the left and right ends, the carrier fixing structure 5 is located above the embedded rail 1, the traction wheel connecting frame 2 and the two ends of the bottom surface of the carrier fixing structure 5 are fixed together by bolts, the traction wheel main body 6 and the traction wheel The wheel connectors 2 are fastened to each other and are close to the inner wall...

Embodiment 2

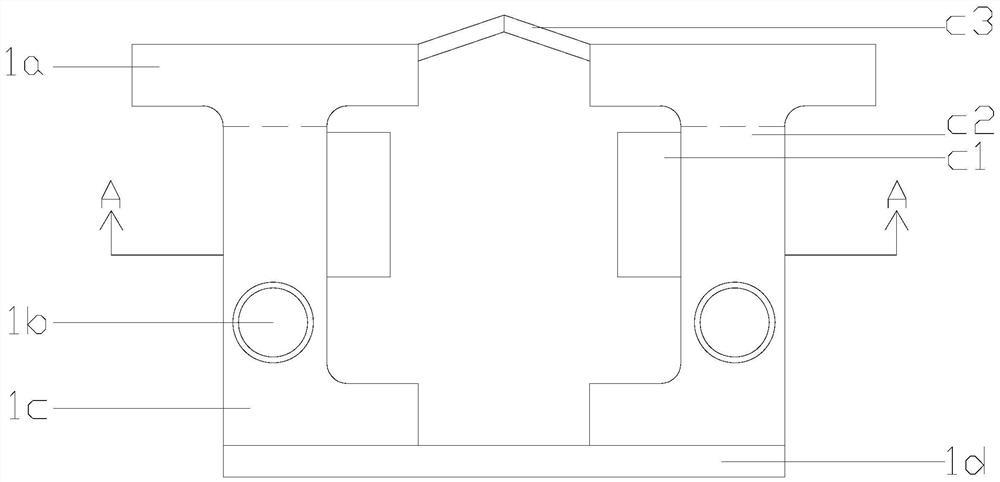

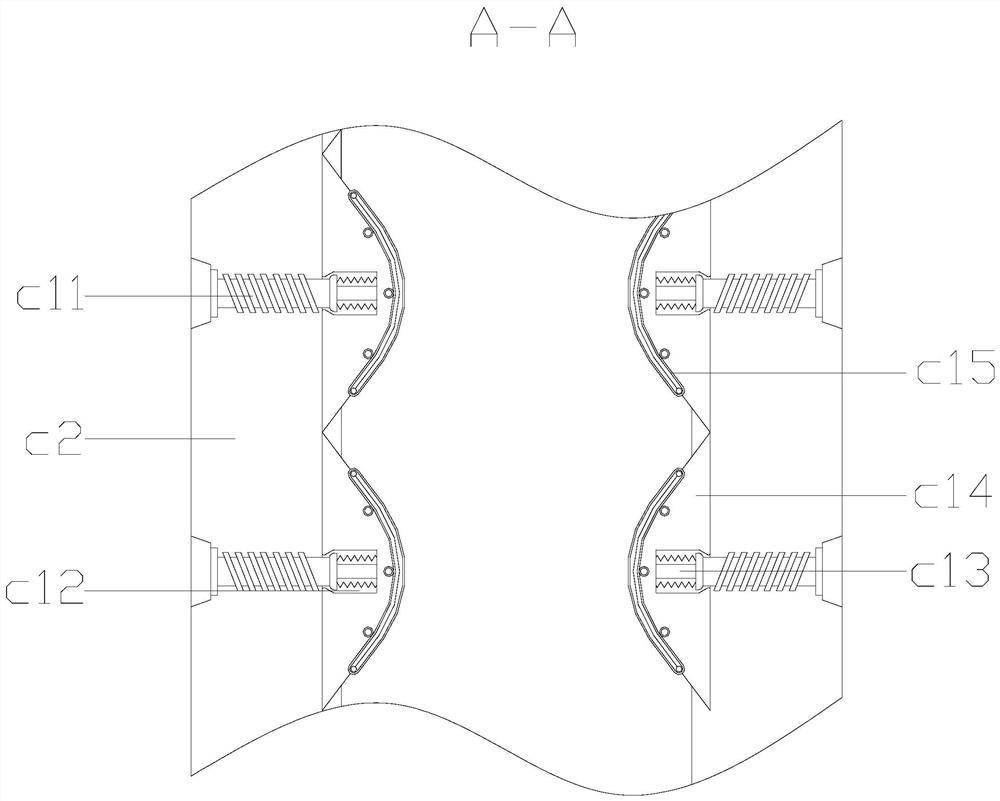

[0030] see Figure 6-Figure 8 , the carrier fixing structure 5 is composed of a carrier fixing chassis 51, a carrier connecting buckle 52, and a deviation correction support device 53. The carrier fixing chassis 51 is horizontally installed above the embedded rail 1, and the carrier connecting buckle 52 Welded with the upper surface of the carrier fixed chassis 51, the deviation correction support device 53 is nested at the bottom of the carrier fixed chassis 51, and the carrier connecting buckle 52 is provided with two and distributed at the left and right ends of the carrier fixed chassis 51 . The vehicle fixed chassis 51 is composed of a chassis body 511, a self-adjusting sliding groove 512, an induction hole 513, a torsion spring 514, and a center of gravity detection plate 515. The chassis body 511 is a rectangular structure, and the self-adjusting sliding groove 512 is nested In the middle of the chassis main body 511, the induction hole 513 is connected to the left and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com