Lifting type tail cover sealing device for concrete stirring transport vehicle and using method

A technology for mixing trucks and sealing devices, which is applied in cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve problems such as leakage of concrete and other materials, inability to guarantee the quality of transportation, and increase in the weight of sealed doors, so as to reduce moisture content. The effect of reducing the amount of loss, improving transportation efficiency, and reducing maintenance difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

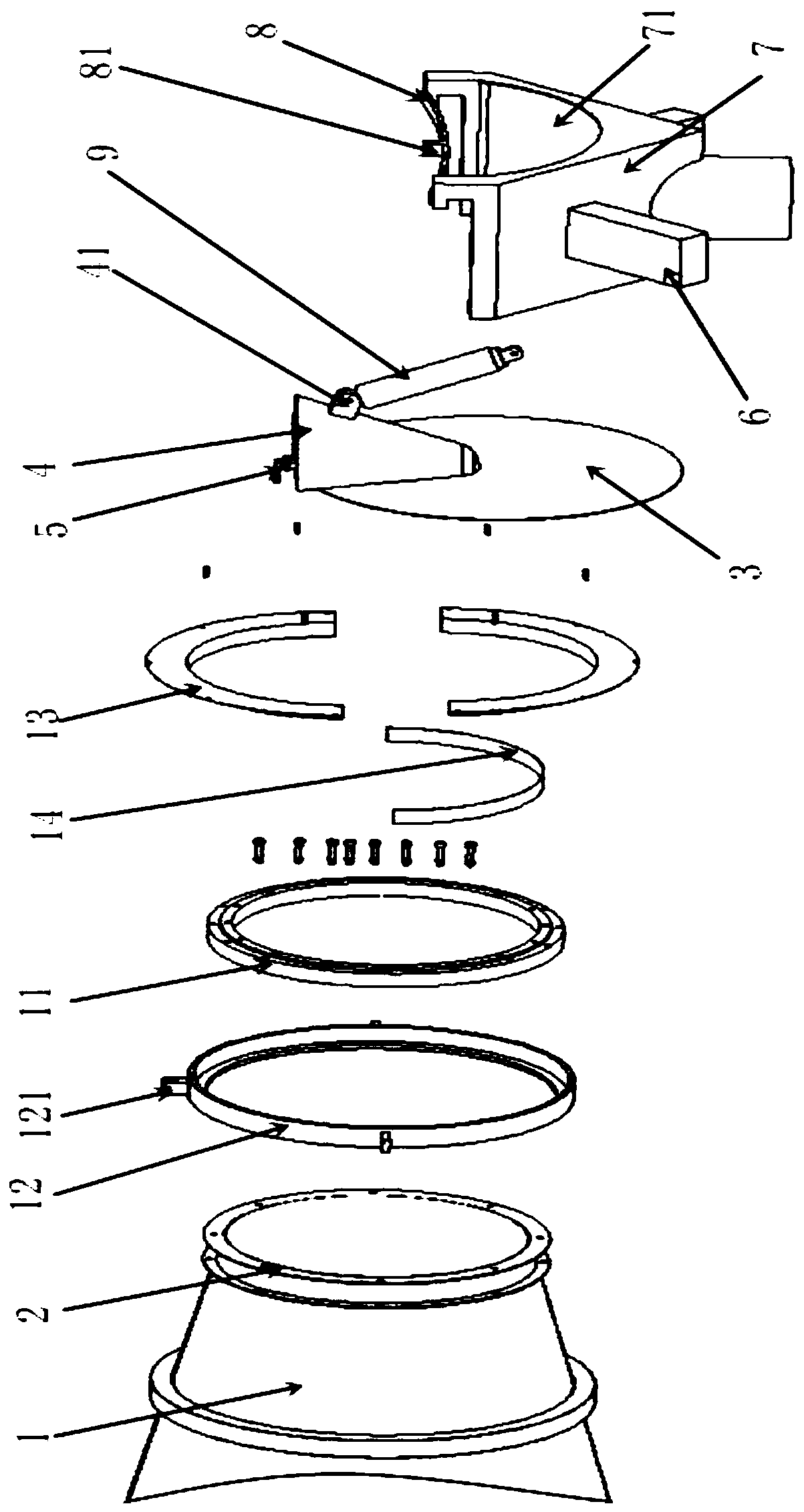

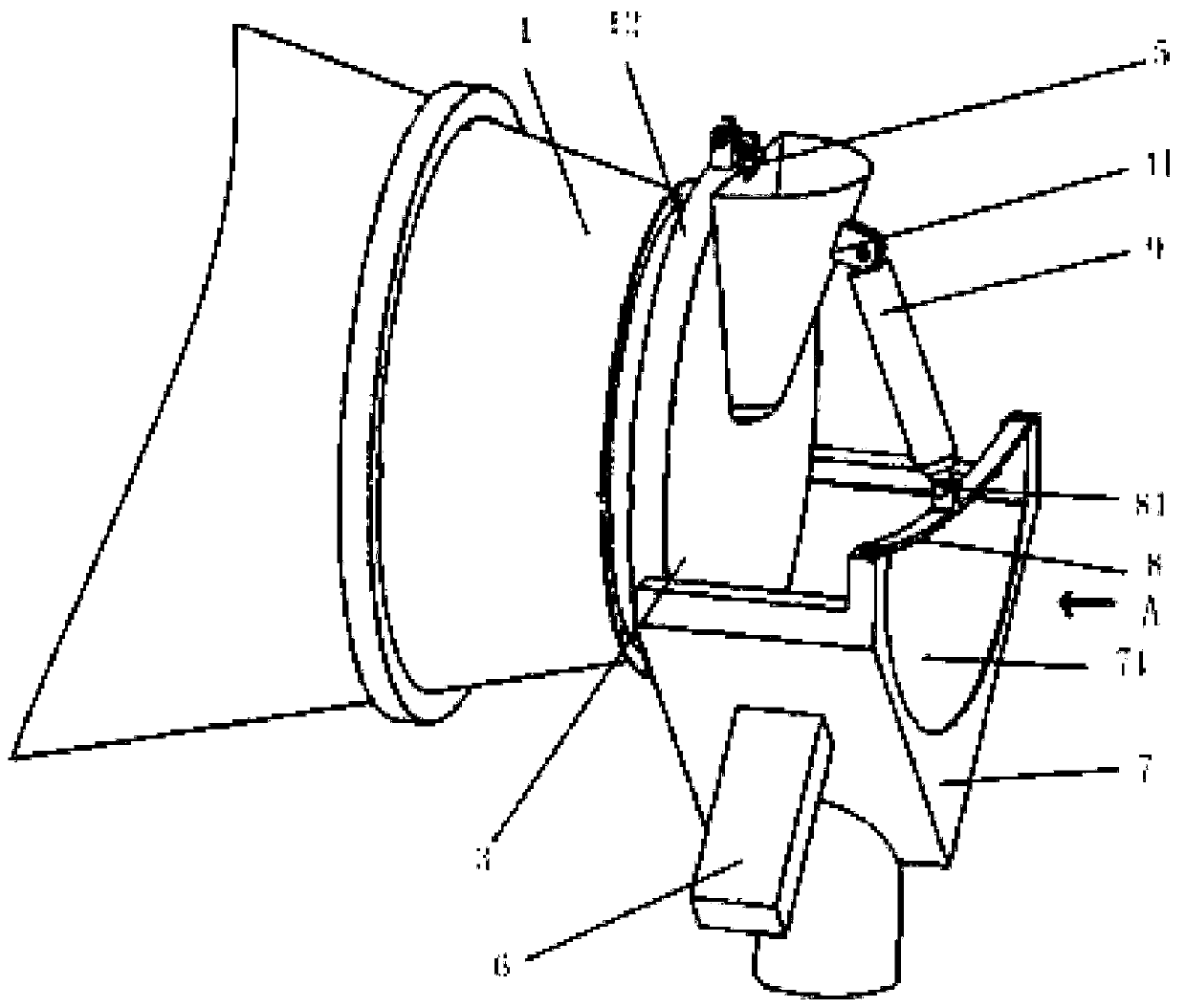

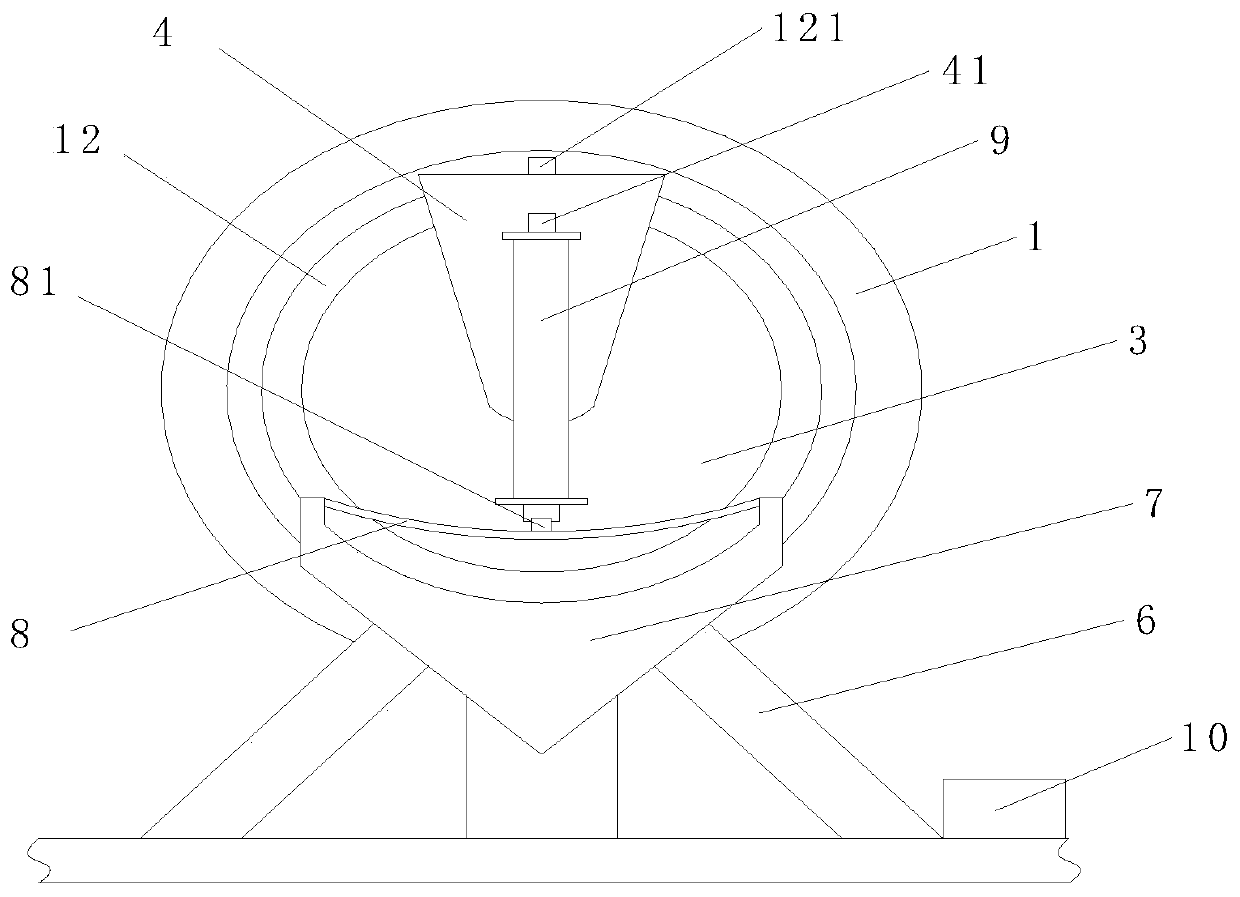

[0048] A lifting tail cover sealing device for a concrete mixer truck, comprising a mixing drum 1, a rotary sealing assembly, a tail cover assembly, a material guide assembly and an opening and closing drive system;

[0049] The tail of the mixing drum 1 is provided with an outlet flange 2, and the outlet flange 2 is evenly opened with oval holes for easy installation. In order to reduce the weight of the sealing door 3 and ensure the sealing effect, a rotary seal is fixedly connected to the outlet flange 2. components;

[0050] The tail cover assembly includes a sealed door 3 and a feed hopper 4; the top of the sealed door 3 is fixed with a connecting rod 5; the feed hopper 4 is welded and fixed on the rear side wall connected to the sealed door 3; the outer peripheral surface of the feed hopper 4 The first connecting ear 41 is fixed by welding;

[0051] The material guide assembly comprises a bracket 6 and a material guide 7, the top of the bracket 6 is welded and fixed on ...

Embodiment 2

[0055] A lifting tail cover sealing device for a concrete mixer truck, comprising a mixing drum 1, a rotary sealing assembly, a tail cover assembly, a material guide assembly and an opening and closing drive system;

[0056] The tail of the mixing drum 1 is provided with an outlet flange 2. In order to reduce the weight of the sealing door 3 and ensure the sealing effect, a rotary sealing assembly is fixedly connected to the outlet flange 2;

[0057] The tail cover assembly includes a sealed door 3 and a feed hopper 4; the top of the sealed door 3 is fixed with a connecting rod 5; the feed hopper 4 is welded and fixed on the rear side wall connected to the sealed door 3; the outer peripheral surface of the feed hopper 4 The first connecting ear 41 is fixed by welding;

[0058] The material guide assembly comprises a bracket 6 and a material guide 7, the top of the bracket 6 is welded and fixed on the side wall of the material guide 7, and the bottom end of the bracket 6 is wel...

Embodiment 3

[0068] When the present invention uses the opening and closing drive system as the hydraulic control system, a method for using the lifting tail cover sealing device for the concrete mixer truck includes the following steps:

[0069] Step 1: When unloading or cleaning in the cylinder, the motor 15 starts to drive the hydraulic pump 16 to rotate to supply oil to the hydraulic control circuit, and at the same time the hydraulic lock 18 is reset, and the first electromagnetic reversing valve 17 controls the flow of hydraulic oil to the first oil pipe;

[0070] Step 2: The first one-way throttle valve 21 on the first oil pipe regulates the speed of the hydraulic oil in the pipeline, and the hydraulic oil enters the left oil chamber of the hydraulic cylinder; the hydraulic oil in the right oil chamber of the hydraulic cylinder flows into inside the fuel tank;

[0071] Step 3: The hydraulic rod of the hydraulic cylinder is stretched out under the action of oil pressure, and at the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com