Glass wiping device for granule counting machine

A particle counting machine and glass technology, which is applied in the field of glass wiping devices for particle counting machines, can solve the problems of easy accumulation of dust on glass, affecting counting accuracy, and counting accuracy, so as to avoid dust adhesion and improve accuracy. , the effect of easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

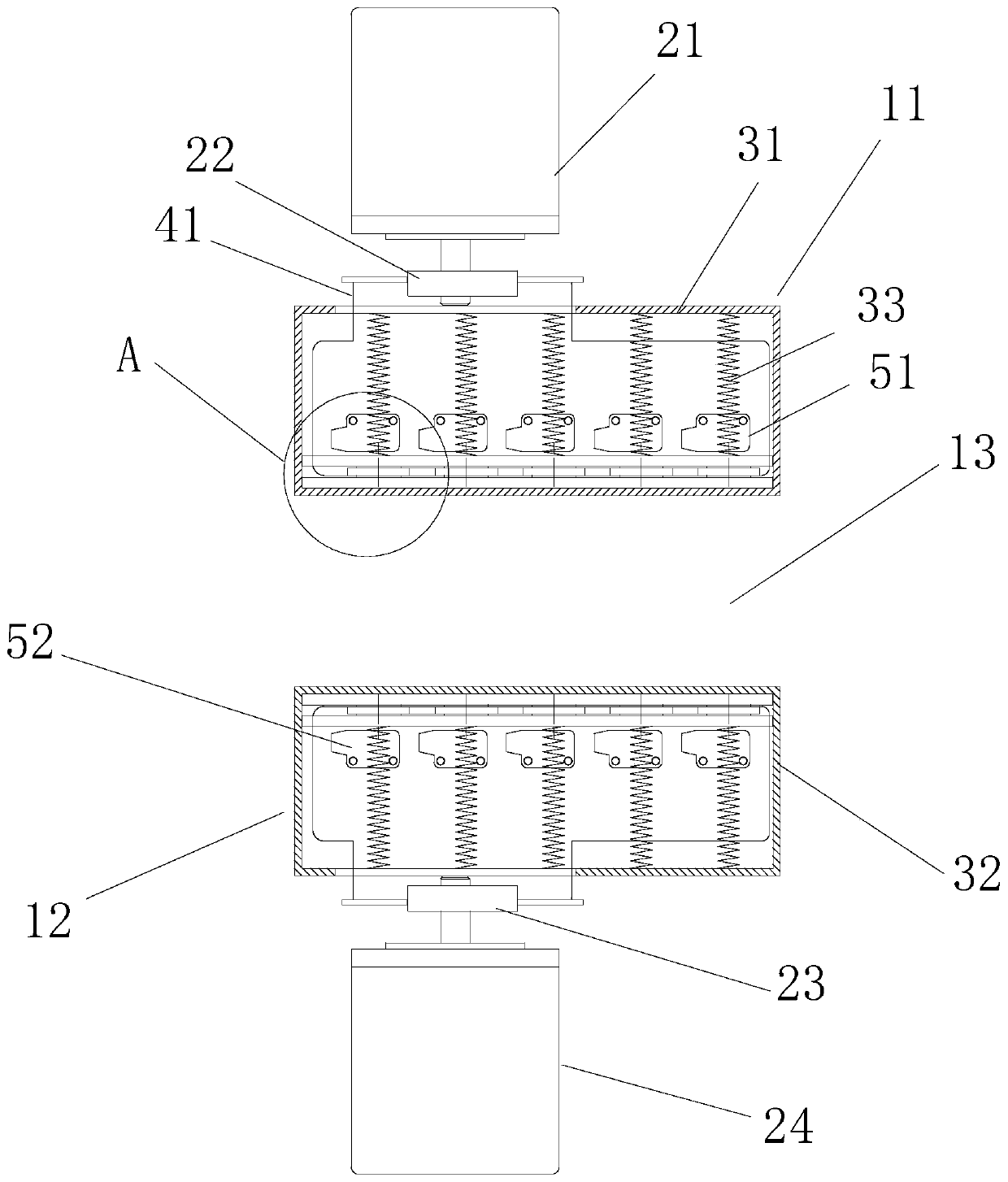

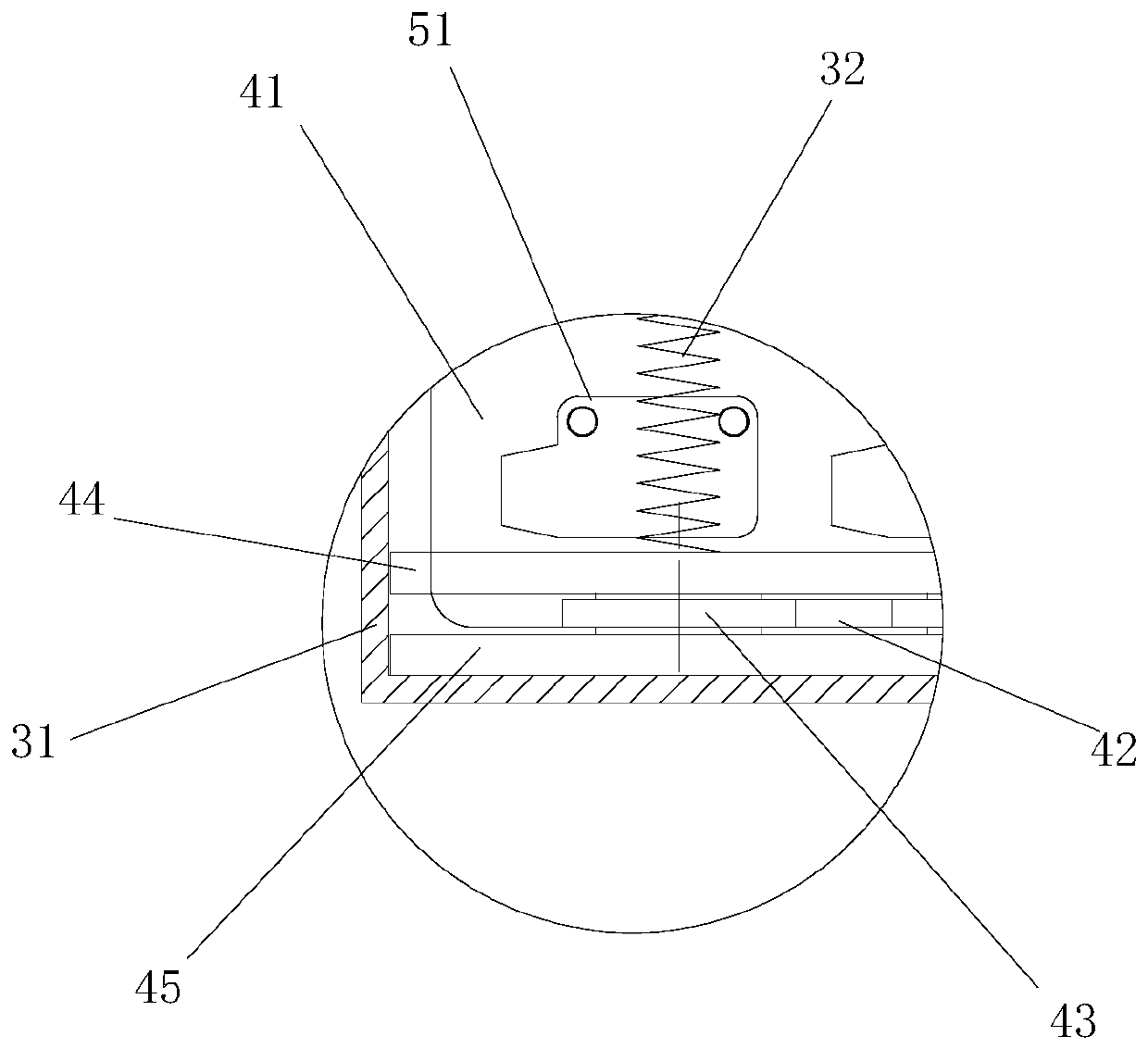

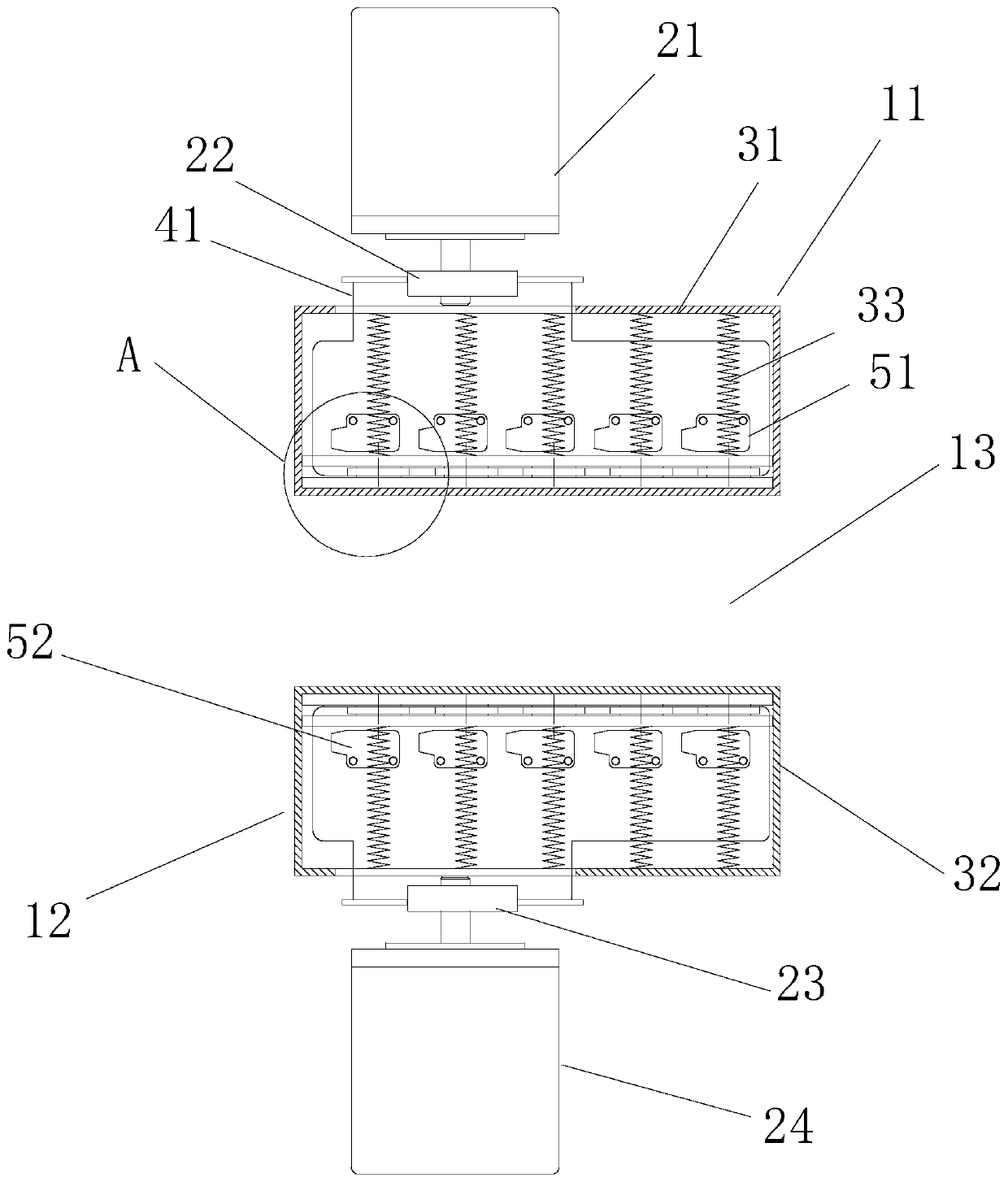

[0017] Example 1 as Figure 1 to Figure 2 As shown, the glass wiping device for counting machine of the present embodiment comprises an infrared emitting unit 11 and an infrared receiving unit 12 arranged symmetrically, the infrared emitting unit 11 comprises a transmitting box 31, the infrared receiving unit 12 comprises a receiving box 32, and the emitting Five infrared transmitters 51 are arranged side by side in the box body 31, five infrared receivers 52 are arranged side by side in the receiving box body 32, and strip-shaped transmission windows are respectively set on one side of the emission box body 31 and the receiving box body 32. The inside of the window is provided with an outer wiping plate 45 suitable for the elongated transmission window, and the outer wiping plate 45 is used to seal the transmission window for the first time to reduce dust from entering the corresponding launch box 31 or receiving box 32; the launch box 31. Reciprocating moving seats 41 are re...

Embodiment 2

[0022] The glass wiping device for the counting machine of the present embodiment comprises a symmetrically arranged infrared emitting unit 11 and an infrared receiving unit 12, the infrared emitting unit 11 comprises a transmitting box 31, the infrared receiving unit 12 comprises a receiving box 32, and the emitting box 31 Five infrared transmitters 51 are arranged side by side in the receiving box 32, and five infrared receivers 52 are arranged side by side in the receiving box 32. One side of the transmitting box 31 and the receiving box 32 is respectively provided with a strip-shaped transmission window. The outer wiping plate 45 that is compatible with the elongated transmission window is used to seal the transmission window first by the outer wiping plate 45 to reduce dust from entering the corresponding launch box 31 or receiving box 32; the launch box 31, receiving box Reciprocating moving seats 41 are respectively arranged in the box body 32, and the ends of each movin...

Embodiment 3

[0027] The glass wiping device for the counting machine of the present embodiment comprises a symmetrically arranged infrared emitting unit 11 and an infrared receiving unit 12, the infrared emitting unit 11 comprises a transmitting box 31, the infrared receiving unit 12 comprises a receiving box 32, and the emitting box 31 Five infrared transmitters 51 are arranged side by side in the receiving box 32, and five infrared receivers 52 are arranged side by side in the receiving box 32. One side of the transmitting box 31 and the receiving box 32 is respectively provided with a strip-shaped transmission window. The outer wiping plate 45 that is compatible with the elongated transmission window is used to seal the transmission window first by the outer wiping plate 45 to reduce dust from entering the corresponding launch box 31 or receiving box 32; the launch box 31, receiving box Reciprocating moving seats 41 are respectively arranged in the box body 32, and the ends of each movin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap