Bedding mortar mold for assisting connection of prefabricated cover beam and prefabricated stand column

A prefabricated cover and column technology, which is applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of reduced waste rate of sitting grouting molds, poor compatibility of sitting grouting molds, unavailable sizes, etc., to avoid grout leakage , not easy to angle deviation, high stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

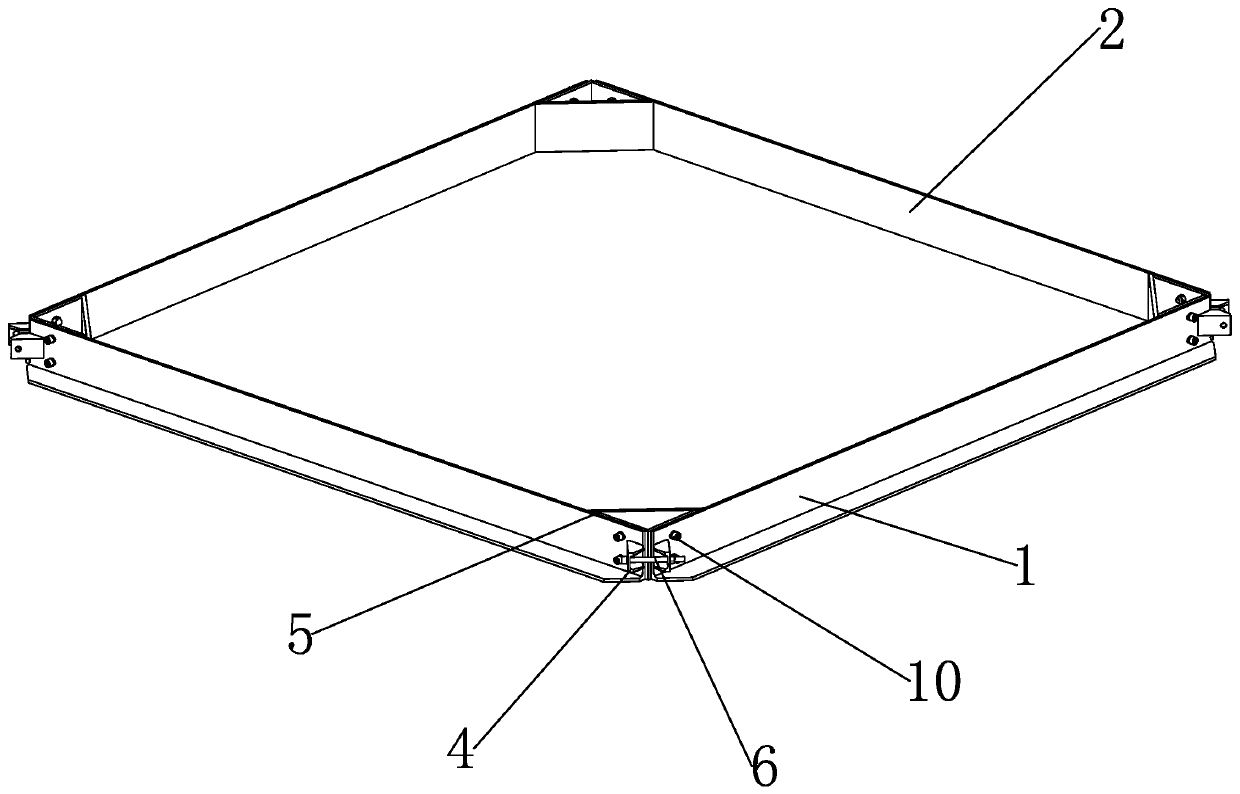

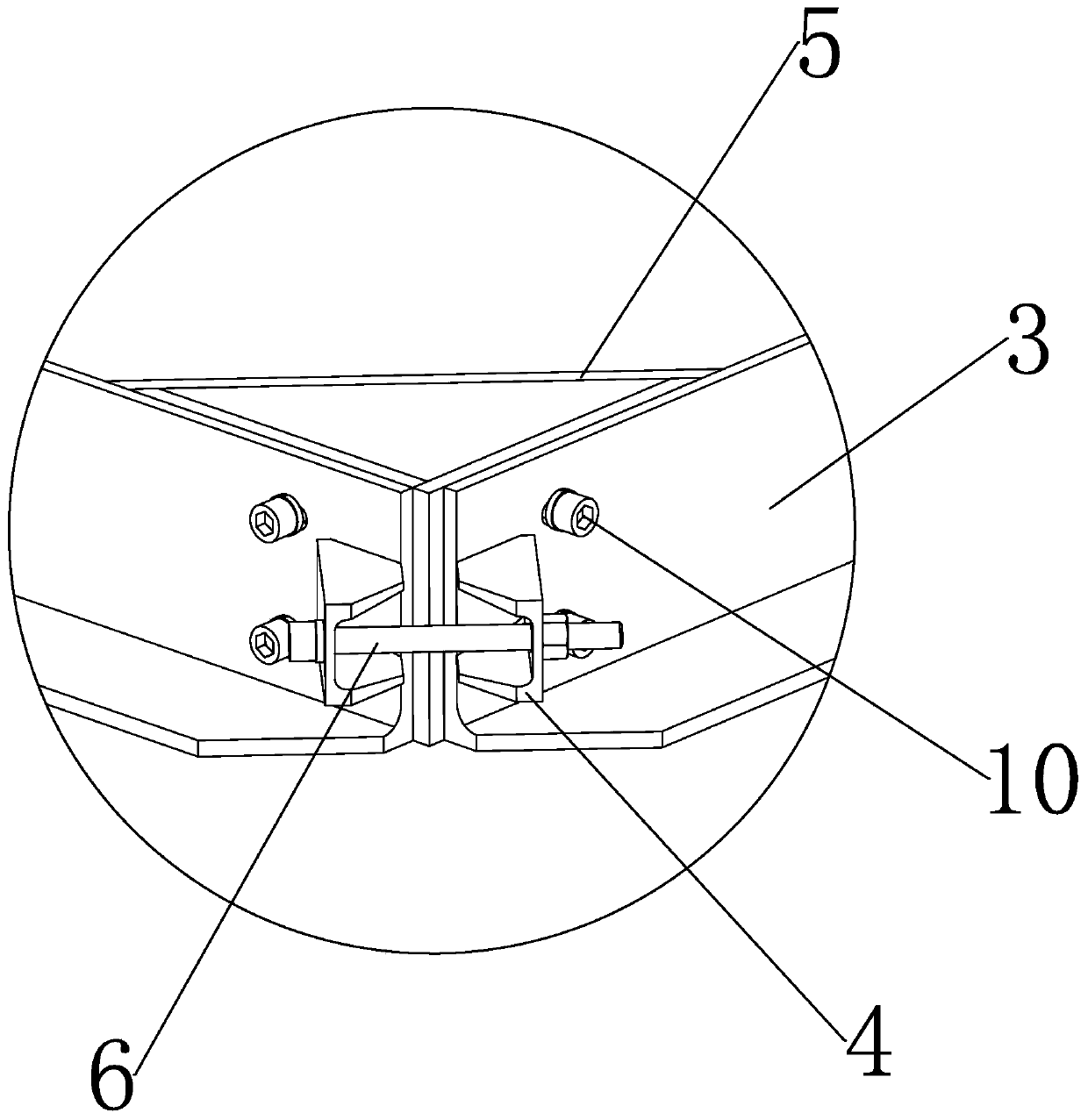

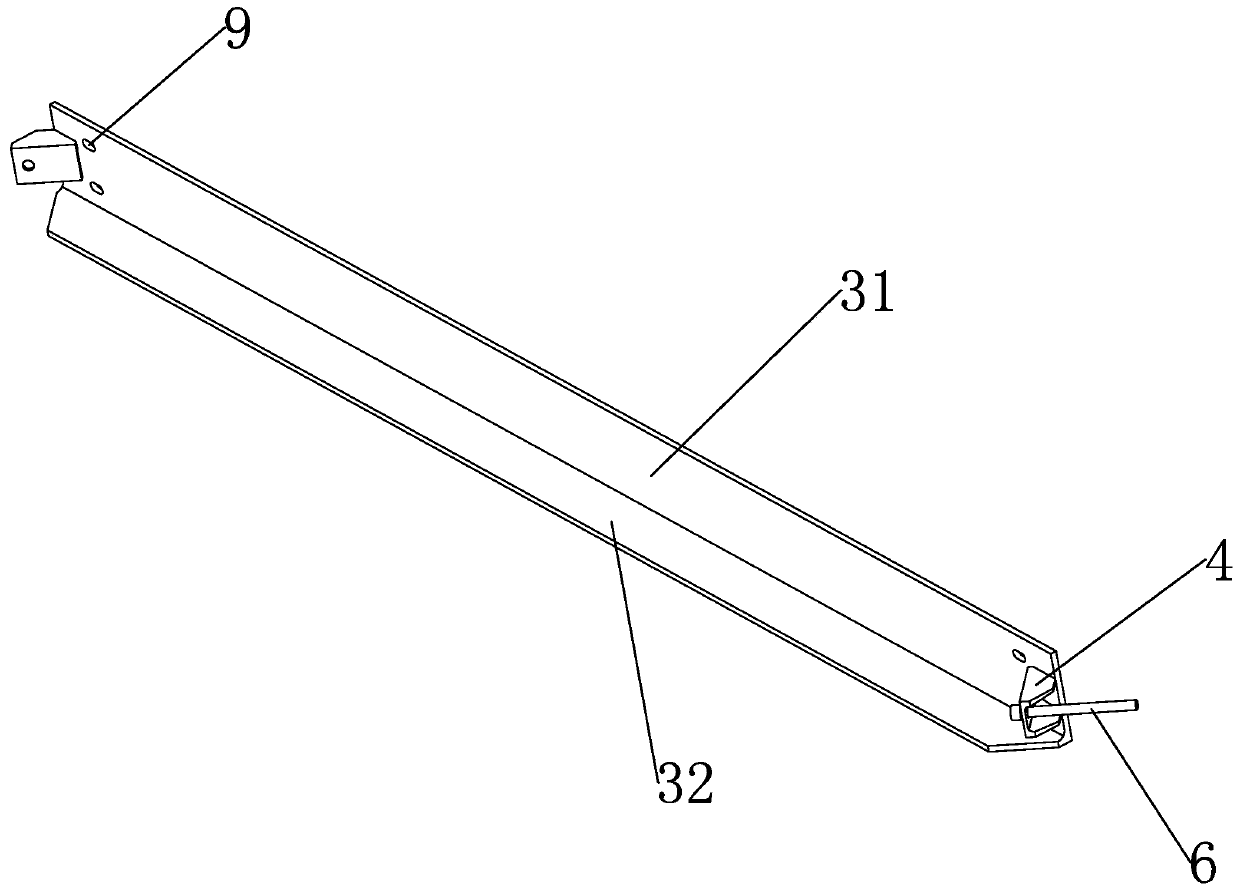

[0028] Such as Figure 1 to Figure 5 As shown, a sitting grouting mold for auxiliary prefabricated cover beam and prefabricated column connection is characterized in that it includes a sitting grouting frame 2 formed by splicing side molds 1 to accommodate the grouting slurry. The side molds include a body 3 and a Two connectors 4 are respectively arranged at both ends of the body in the length direction, and a slurry stopper 5 is provided at the corner of the sitting frame. Part and the first fixing part 6 cooperate to form a detachable connection; the section of the body is "L" shape, the body includes a first folded plate 31 and a second folded plate 32, the second folded plate includes a large end and a small end, The large end of the second folded plate is fixedly connected to the lower edge of the first folded plate, and the small end of the second folded plate arranged along the normal direction of the first folded plate is located outside the sitting frame; the stopper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com