Split type range hood

A range hood, split-type technology, applied in the range hood field, can solve the problem that the range hood cannot be completely hidden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

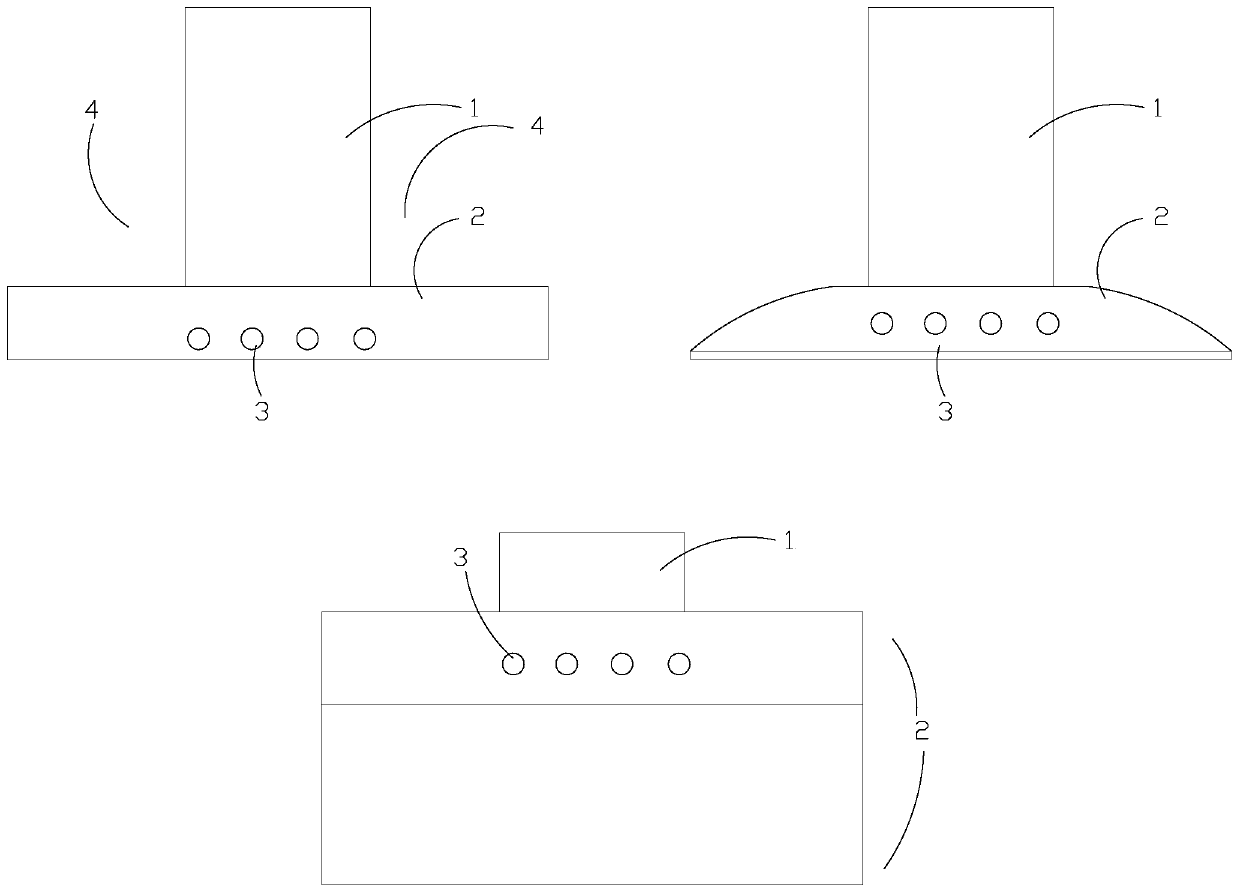

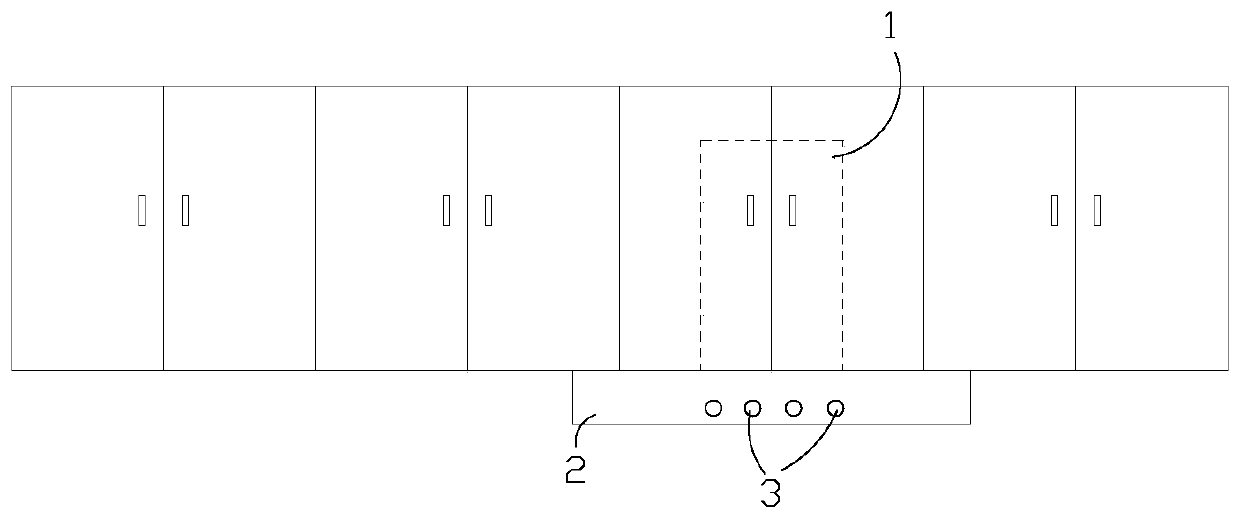

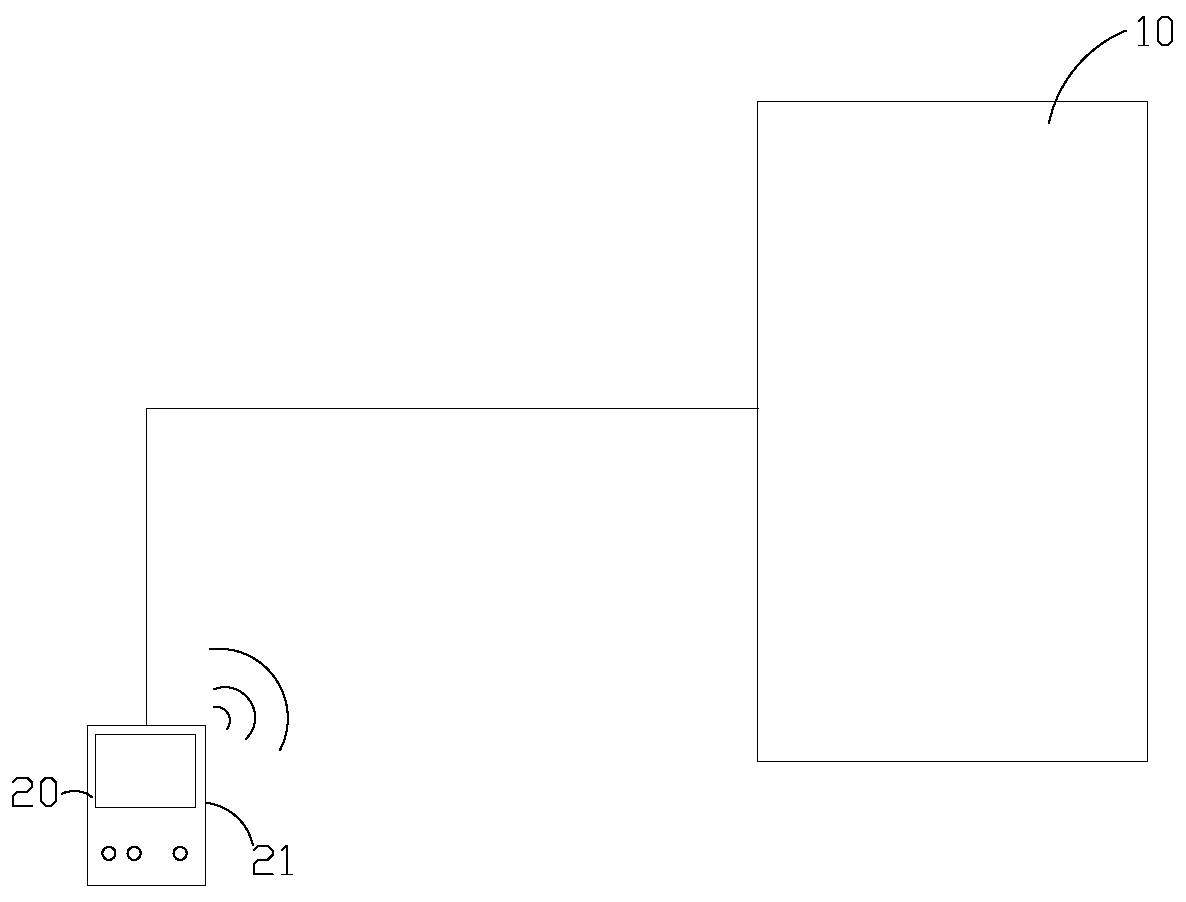

[0039] Such as Figures 3 to 16 shown, especially refer to the Figures 3 to 6 As shown, a split range hood includes a main body casing 10 and a controller 20, the controller 20 is set separately from the main body casing 10, that is to say, the controller 20 is set separately, and the controller 20 It is not provided on the main body casing 10 .

[0040] The controller 20 is used to control the working mode of the range hood. In practice, the controller 20 can control the start-stop mode of the range hood, and the controller 20 can also control the air volume of the range hood. The controller 20 can also control the lighting state of the range hood and so on, that is to say, the user can realize complete control of the range hood through the controller 20 .

[0041] Such as Figure 4 As shown, the main body casing 10 has an air duct 11 , a fan 12 is disposed in the air duct 11 , and the controller 20 controls the working state of the fan 12 .

[0042] During specific impl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com