Weighing sensor overload protection method and system

A weighing sensor and overload protection technology, which is applied to the detailed information of weighing equipment, instruments, weighing, etc., can solve the problems of sensor damage, sensor breakage, casting billet jamming, etc., and achieve easy implementation, remarkable effect, and systematic The effect of rigorous operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

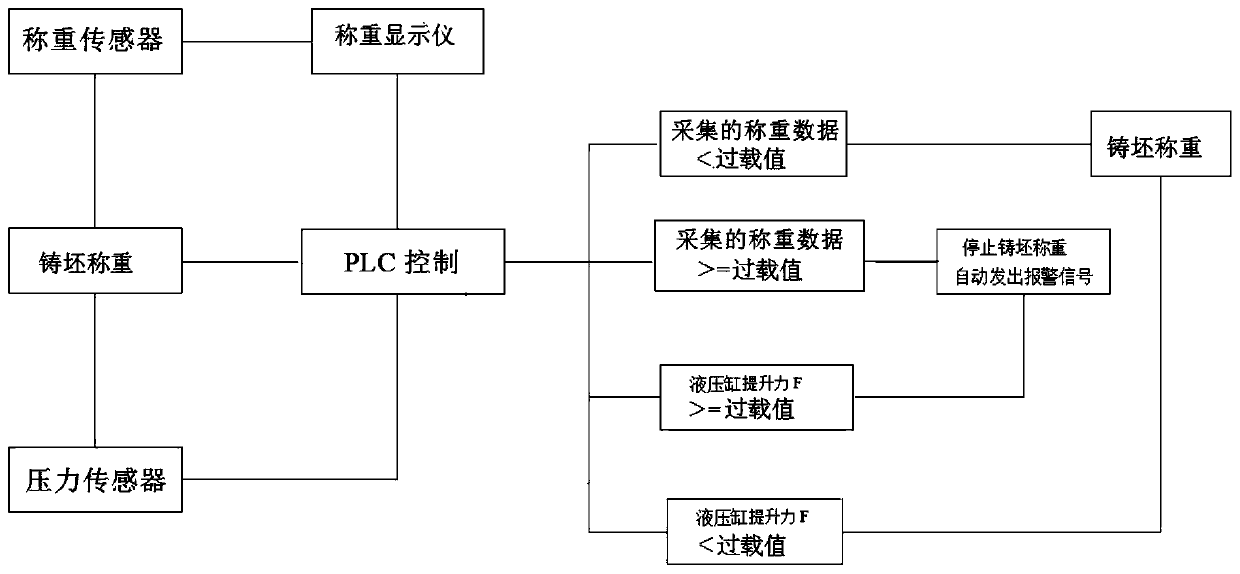

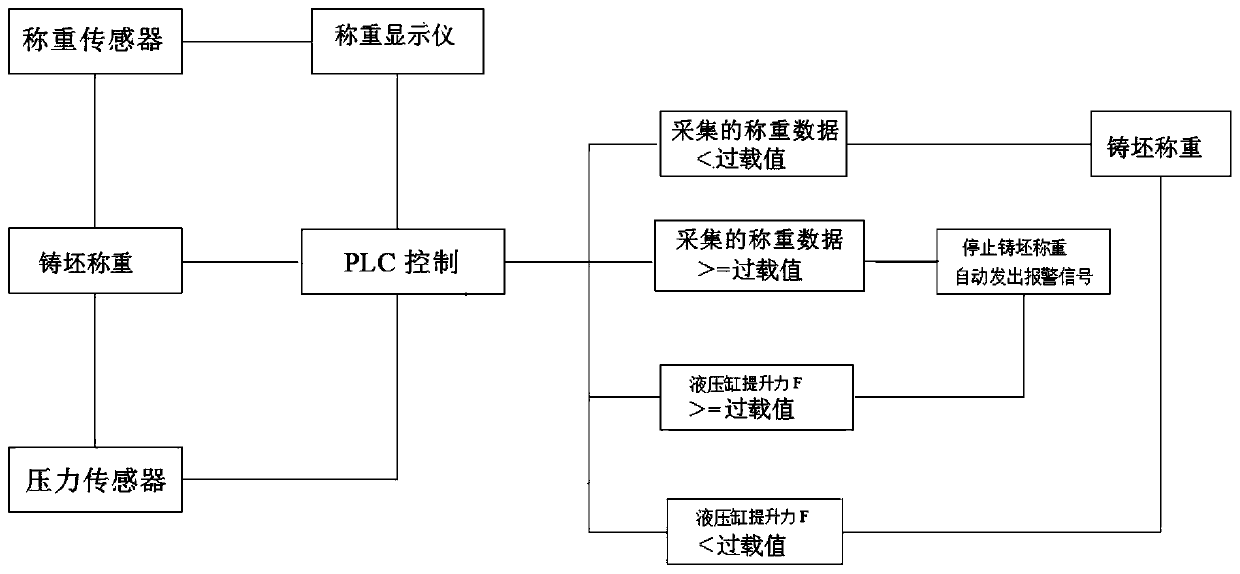

[0031] The following will clearly and completely describe the technical solutions in the embodiments of the present invention in conjunction with the accompanying drawings in the embodiments of the present invention:

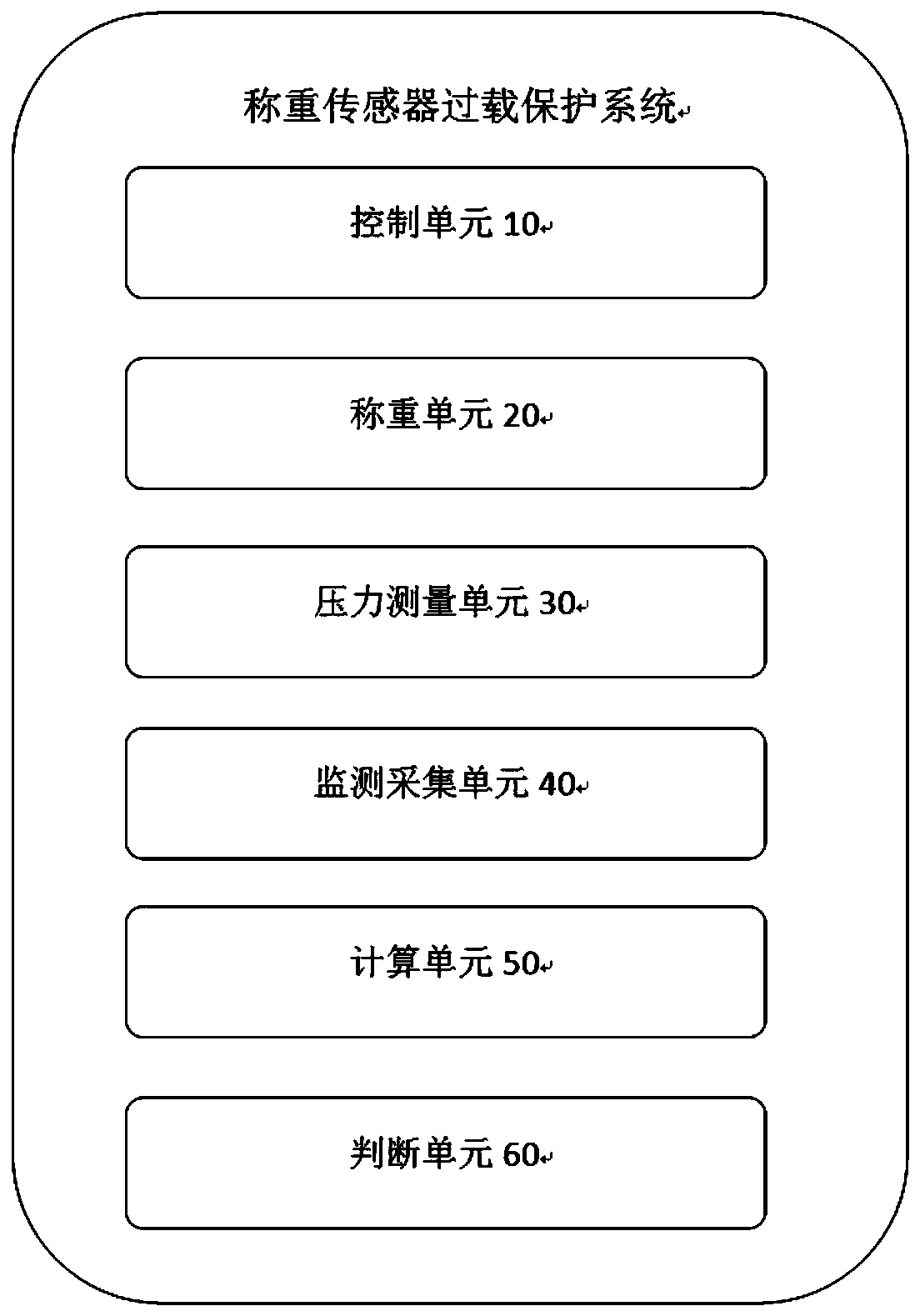

[0032] figure 2 Schematically shows the structure of the load cell overload protection system. Such as figure 2 As shown, a load cell overload protection system provided by the present invention includes: a control unit 10 , a weighing unit 20 , a pressure measurement unit 30 , a monitoring and acquisition unit 40 , a calculation unit 50 , and a judgment unit 60 .

[0033] In the present invention, the control unit 10 adopts a PLC controller for automatic control, and is used to control the start and stop of casting slab weighing, and / or realize the functions of the monitoring and collecting unit 40 , the calculating unit 50 and the judging unit 60 . PLC controller (Programmable Logic Controller, Programmable Logic Controller) is used for control, flexible a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com